Novel water pump

A water pump, a new type of technology, applied in the direction of pump components, pump control, variable-capacity pump components, etc., can solve the problems that the drainage pipe cannot automatically spray at multiple angles, the spraying distance is fixed, and it is inconvenient to use, so as to speed up flow mixing and speed up Circulation, the effect of expanding the spraying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

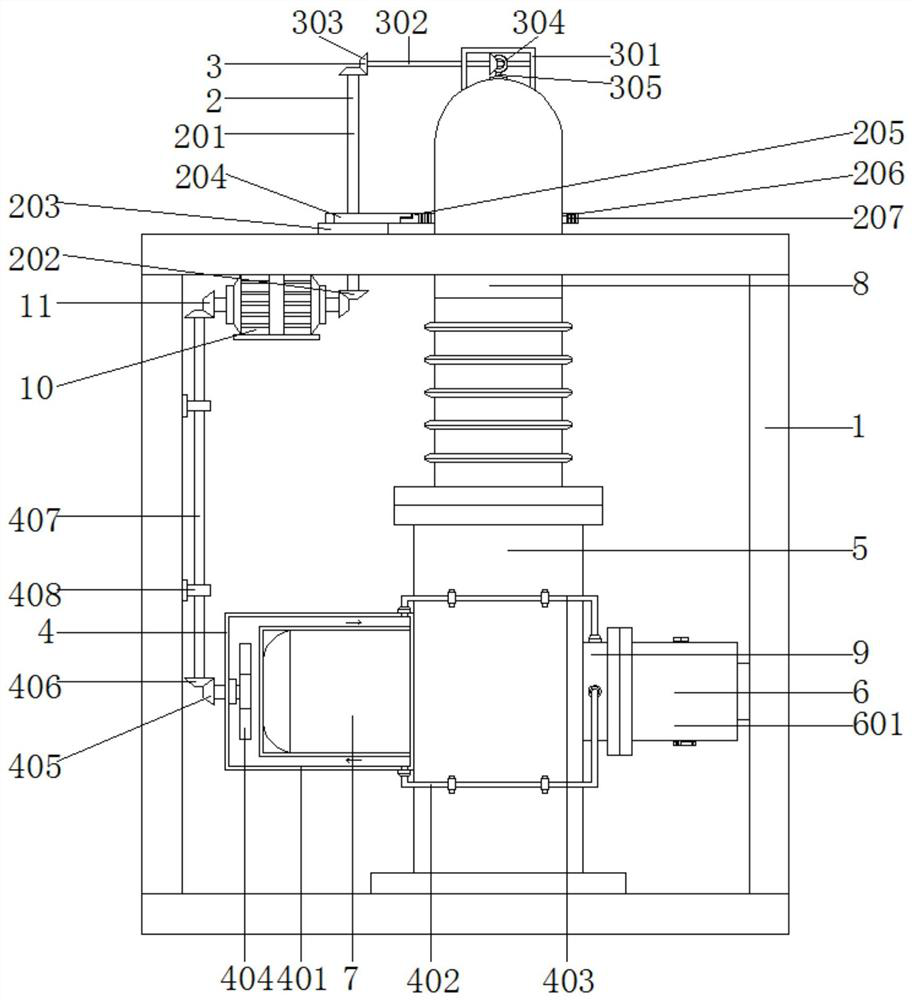

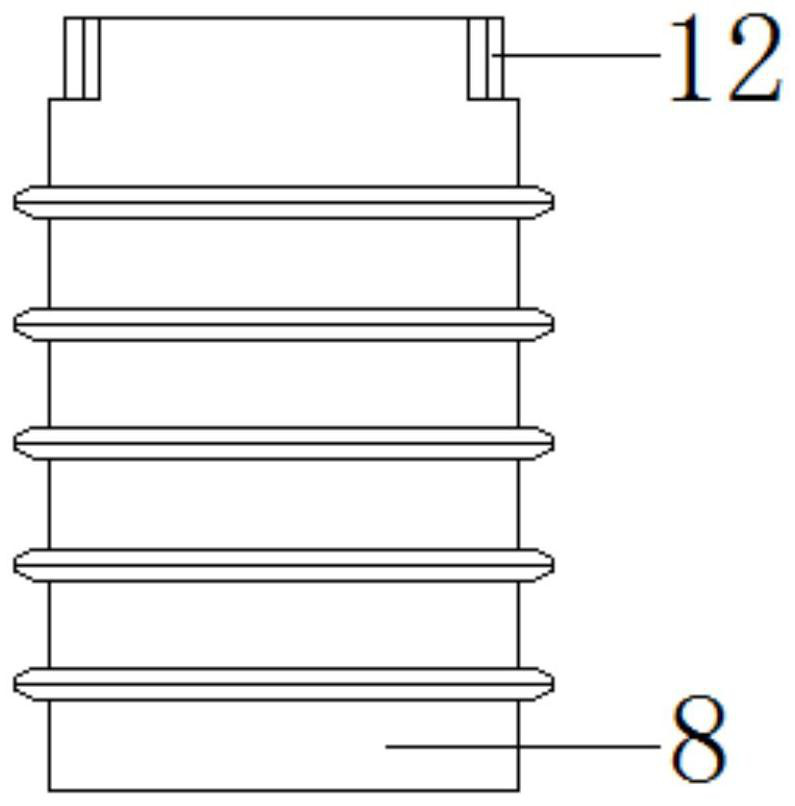

[0046] see Figure 1-4 and Figure 12 , a new type of water pump, comprising a frame 1 and a water pump main body 5, the water pump main body 5 is fixedly connected above the bottom of the frame 1, a driving motor 7 is installed on one side of the water pump main body 5, and a connecting pipe 9 is installed on the other side, the water pump main body 5 The top of the drainpipe 8 is provided with a drainpipe 8, and the bottom end of the drainpipe 8 passes through the top of the frame 1, and a sealed bearing 12 is arranged between the bottom end and the top of the water pump main body 5; 5 between the rotary connections.

[0047] One side of the drain pipe 8 is provided with a first adjustment mechanism 2, the first adjustment mechanism 2 includes a first transmission rod 201, a first bevel tooth 202, a first gear 203, a movable rod 204, a moving plate 205, and a semicircular tooth pattern. Plate 206, rectangular toothed plate 207, slide plate 208, clip 209 and second gear 210...

Embodiment 2

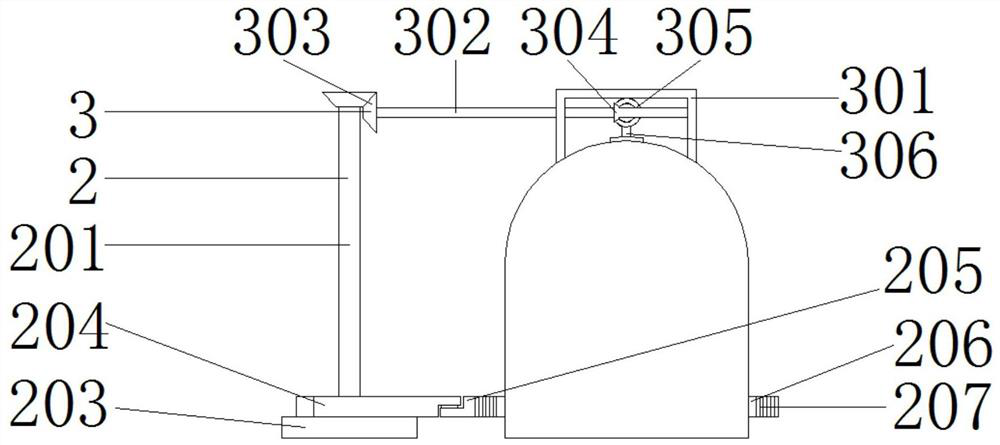

[0050] see figure 1 , 3 , 5 and Figure 12 , the top of the drain pipe 8 is provided with a second adjustment mechanism 3, the second adjustment mechanism 3 includes a concave plate frame 301, a second transmission rod 302, a second bevel tooth 303, a third bevel tooth 304, a support rod 305, a curved rod 306, connecting rod 307 and blocking sheet 308; the top of the drain pipe 8 is provided with a concave plate frame 301, the inside of the concave plate frame 301 is provided with a second transmission rod 302, and the two ends of the second transmission rod 302 are provided with a second Bevel teeth 303, one side of a set of second bevel teeth 303 is engaged with third bevel teeth 304, one side of the third bevel teeth 304 is provided with a curved rod 306, and the two ends of the curved rod 306 are provided with support rods 305, And the middle end is provided with a connecting rod 307 , one end of the connecting rod 307 is provided with a blocking piece 308 , and one end ...

Embodiment 3

[0055] see figure 1 and Figure 6 , the outside of the drive motor 7 is provided with a water-cooling assembly 4, the water-cooling assembly 4 includes a transparent shell 401, a water inlet hose 402, a water outlet hose 403, a stirring leaf 404, a fourth bevel tooth 405, a fifth bevel tooth 406, a third transmission Rod 407, fixing piece 408 and guide pipe 409; The outside of drive motor 7 is provided with transparent shell 401, and the top of one end of transparent shell 401 is provided with water outlet hose 403, and one end of water outlet hose 403 is connected with the top of connecting pipe 9, transparent The bottom of one end of the housing 401 is provided with a water inlet hose 402, and one end of the water inlet hose 402 is connected to the side wall of the connecting pipe 9, and one end of the water inlet hose 402 is provided with a guide tube 409, and the guide tube 409 is arranged on the connecting pipe 9. Inside the pipe 9 ; the other end of the transparent casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com