a digester

A biogas digester and pond body technology, applied in the field of biogas digesters, can solve the problems of affecting gas production, affecting the living environment, easy to form scum, crusting, etc., to reduce pollution, protect the ecological environment, reduce crusting and pH imbalance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

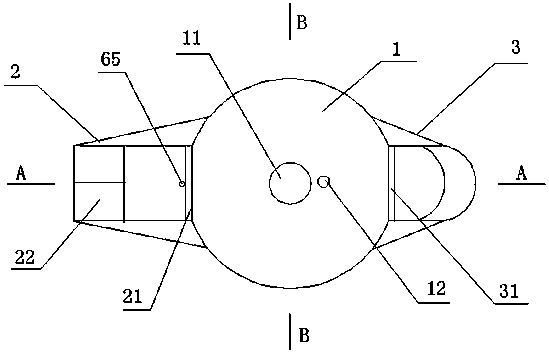

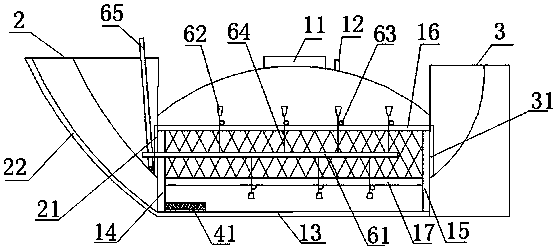

[0026] A biogas digester, comprising a pond body 1, a feed channel 2, a discharge channel 3, a slag cleaner 4, a stirring system, and two material boxes,

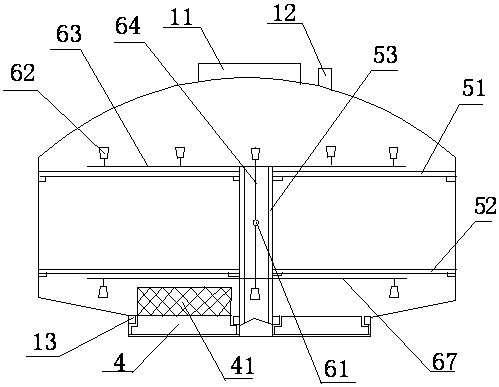

[0027] One end of the tank body 1 is provided with a feed channel 2, the other end is provided with a discharge channel 3, the top is provided with a skylight 11 and an air duct 12 with a cover, and two channels 13 are provided at the bottom of the pool, and the channels 13 are slidingly connected. A number of slag cleaners 4, two front columns 14 are arranged side by side at the front end of the middle part of the pool bottom, and two rear columns 15 are arranged side by side at the rear end. Connected by the lower crossbeam 17, the upper crossbeam 16, the lower crossbeam 17 and the channel 13 are arranged in the same direction,

[0028] The material box includes an upper grid plate 51, a lower grid plate 52, and a vertical grid plate 53. The upper and lower grid plates are arranged in parallel, and one side of the upper g...

Embodiment 2

[0041] Stirring system comprises connecting rod 61, some stirring blades 62, two paddle shafts 63, some stirring blade arms 64, remote rod 65, cross bar 66, and connecting rod 61 is positioned between two hoppers, and connecting rod 61 one end and remote The end of the rod 65 is hinged, the middle part of the remote rod 65 is hinged with the cross bar 66 installed on the discharge channel wall, the upper and lower sides of the connecting rod 61 are hinged with one end of the stirring blade arm 64, and the paddle shaft 63 is installed on the top of the upper beam 16, At the lower part of the lower beam 17, the stirring blade arm 64 is hinged with the paddle shaft 63, and a plurality of stirring blades 62 are installed at intervals on the paddle shaft 63.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com