Mini mixer capable of uniform mixing gas mixture rapidly, and preparation method

A uniform mixing and micro-mixer technology, which is applied in mixing methods, fluid mixers, chemical instruments and methods, etc., can solve problems such as unsatisfactory quantity requirements and small size, and achieve enhanced mixing performance and increased contact area , is conducive to the effect of gas mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] Embodiment: Application of the new T-shaped micro-mixer in the micro-thermal photoelectric system

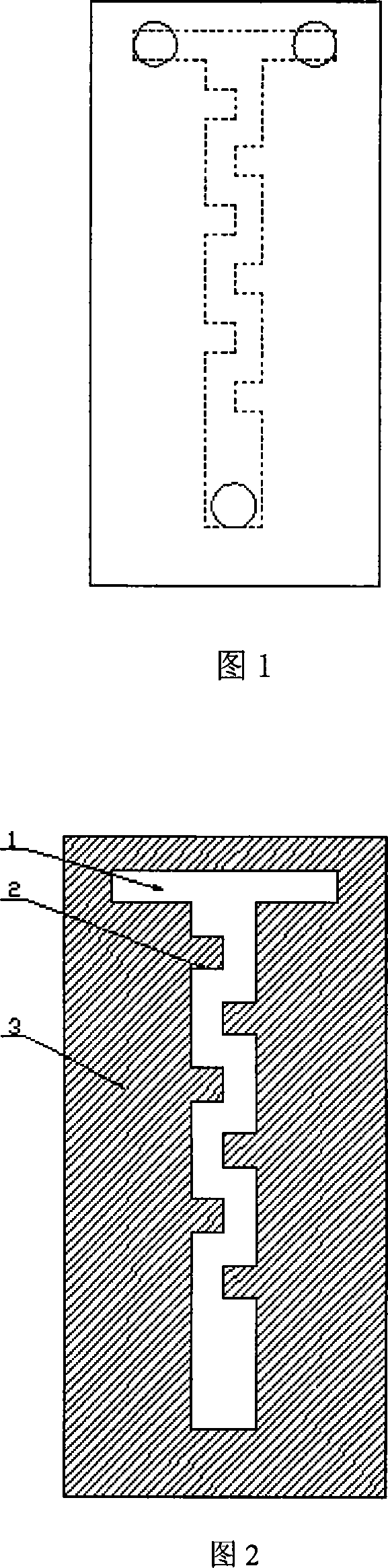

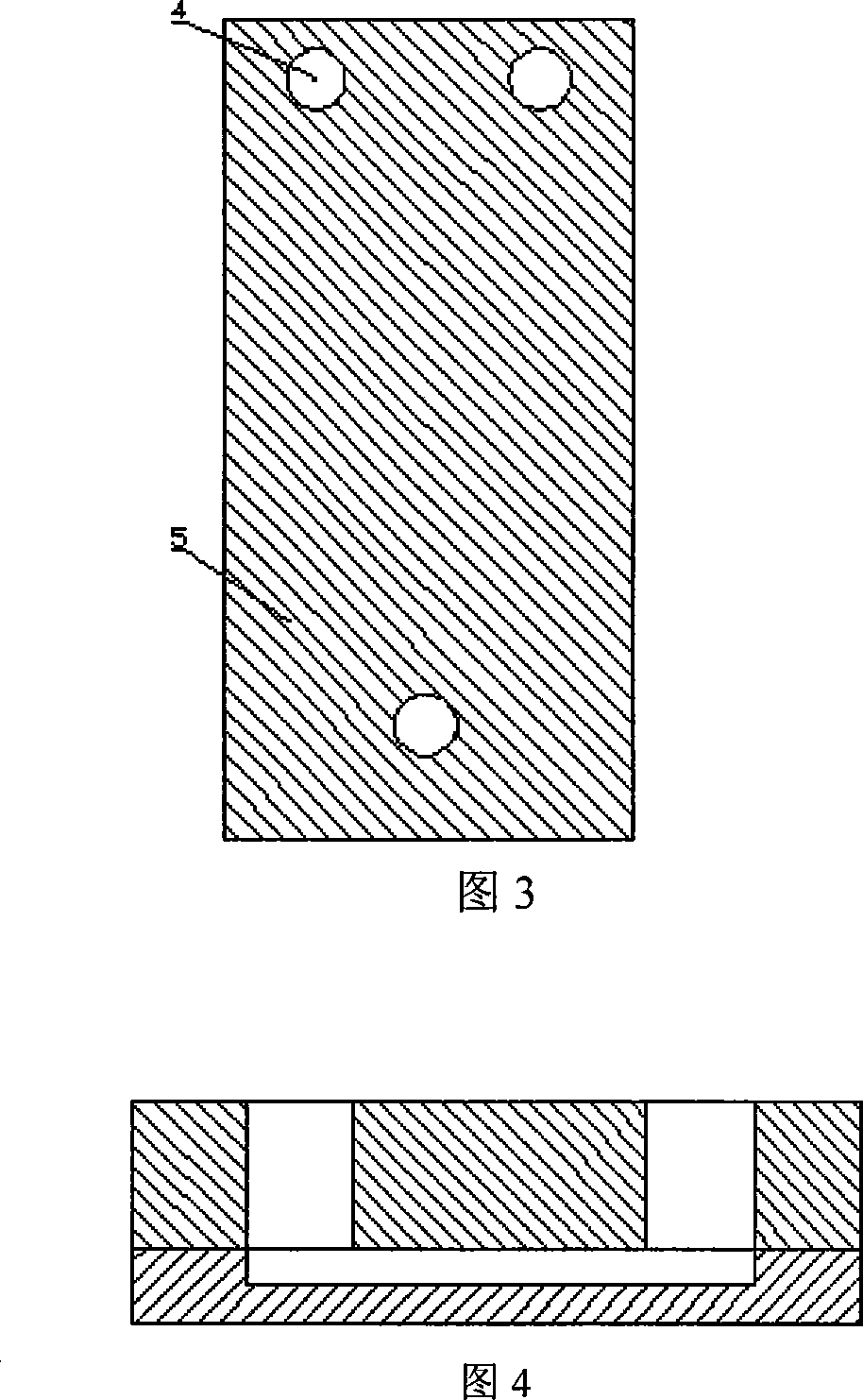

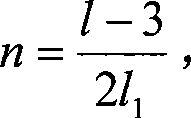

[0016] In the micro-thermal photoelectric system, hydrogen and oxygen mixed in advance are required, and the mixed gas is introduced into the combustion tube for combustion. Therefore, the micro-mixer for mixing is more important, and the micro-mixing channel of the present invention adds convex The new micro-mixer of the ridge (2) enables fast and relatively uniform mixing. Firstly, on a 20×10×0.5mm silicon plate (3), an incomplete T-shaped groove with a depth of 250 μm and 6 cube ridges with a side length of 250 μm is obtained by photolithography and etching, and the length of the mixing channel is It is 16mm wide and 0.5mm wide, and then bonded with 7740 heat-resistant glass with a thickness of 500μm and a diameter of 2mm holes corresponding to the three ports of the T-shaped micro-mixer, making it a closed micro-pipe , make a good interface on the hole, plug in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com