Novel bag cage head integration part

An integrated part and head technology, applied in the field of air box type bag filter and bag cage head, can solve the problems of increased production cost, shortened equipment maintenance cycle, easy occurrence of de-soldering, etc., to reduce production cost and save money. Effect of processing steps and reduction of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

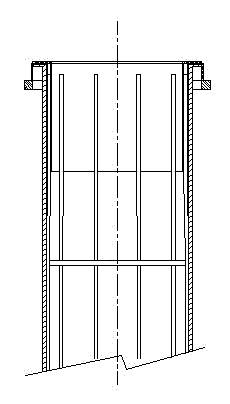

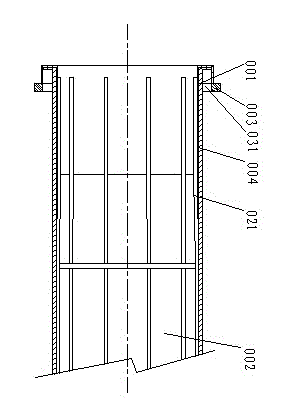

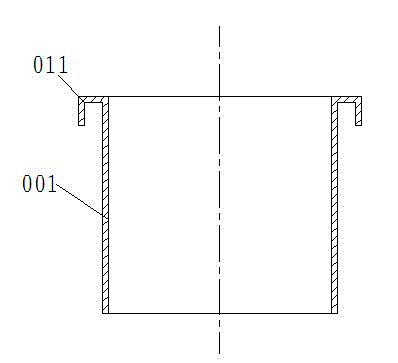

[0011] A new type of bag cage head assembly, including a cylindrical base 001, one end of the base 001 is folded outward to form a circle of flange 011, the flange 011 is in the shape of a "7", and the cylindrical base The length of 001 is 80cm~140cm. When manufacturing the bag cage, put the cylindrical base on the longitudinal rib 021 of the cage body 002, and weld and fix it one by one. The flange 011 hangs and fixes the cage body 002 in the flower plate hole 031 of the flower plate 003, the filter bag 004 is placed on the cage body 002, and the head of the filter bag 004 is inserted into the gap of the "7" shaped flange 011. The head of the filter bag 004 is effectively protected. By setting a cylindrical base 001 of 80cm~140cm, the filter bag 004 on it can be effectively protected from being damaged by high-pressure gas injection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com