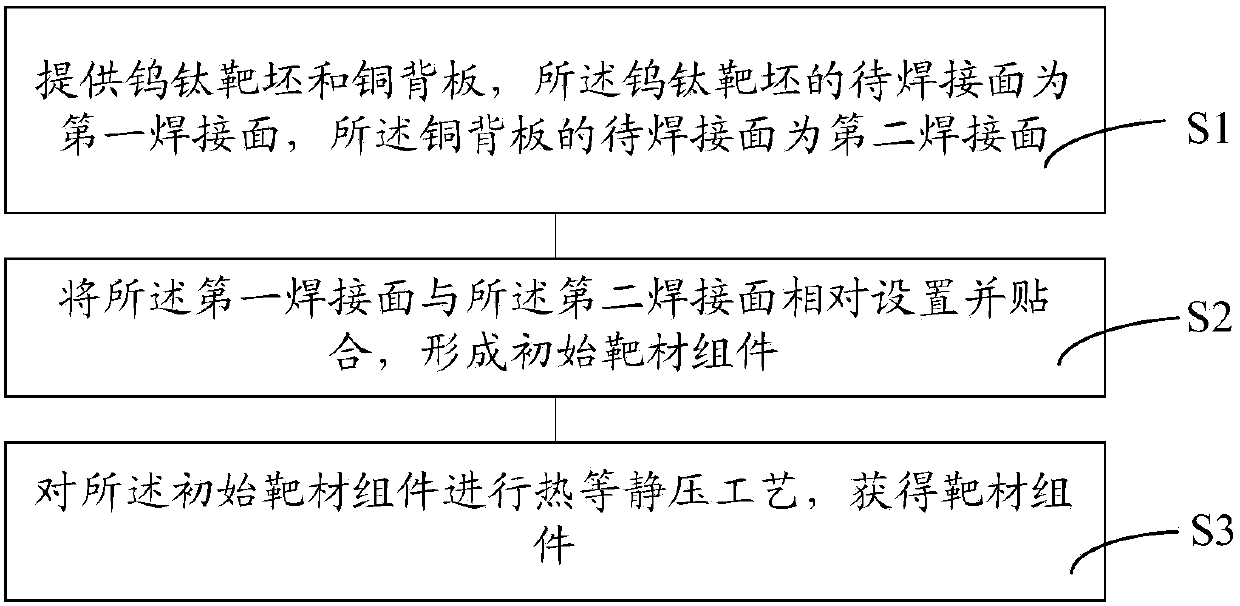

Manufacturing method of target module

A manufacturing method and component technology, which is applied in the field of target component manufacturing, can solve the problems that the target component yield needs to be improved, and achieve the effects of high production process stability, improved bonding strength, and simple welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

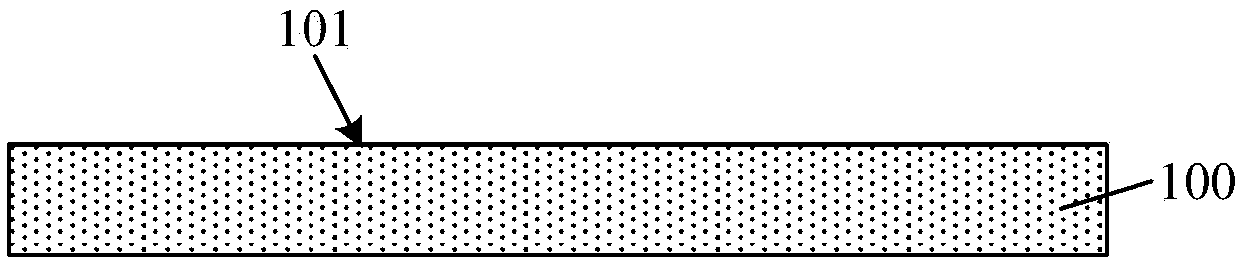

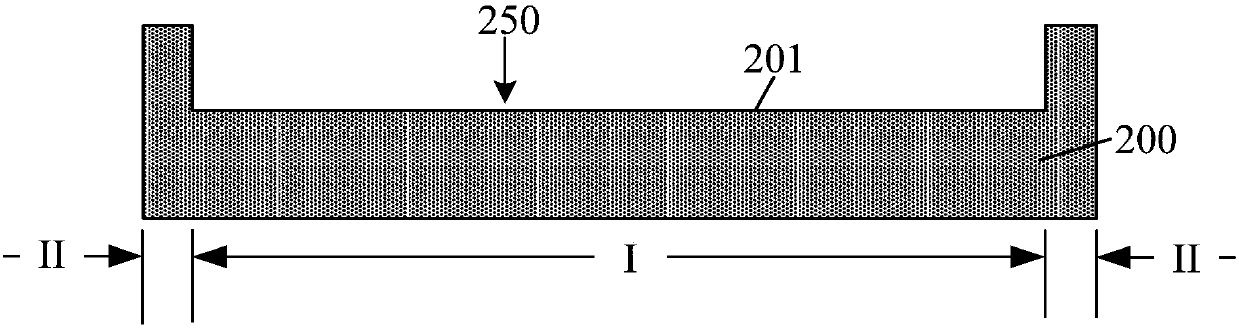

Embodiment Construction

[0028] It can be seen from the background art that the yield rate of target components in the prior art needs to be improved. Analyze the reasons for this:

[0029] At present, the brazing process is mainly used to realize the welding of the WTi target blank and the Cu back plate to form the target assembly. The brazing process uses solder with a melting point lower than that of the target blank and the back plate, such as indium or tin. During the brazing process, the target blank and the back plate are heated at a temperature lower than the melting point of the target blank and the back plate and higher than the melting point of the solder. After the solder is melted, the surface to be welded of the target blank is It is set opposite to the surface to be welded of the back plate and attached, and the solder diffuses with the target blank and the back plate to achieve a firm connection. However, during the use of the target assembly, when the sputtering power is increased t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com