Safety sucker of solar cell string

A solar cell and sucker technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as bending and twisting deformation, desoldering, and hidden defects of battery sheets, and achieve the effect of eliminating bending and twisting deformation and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

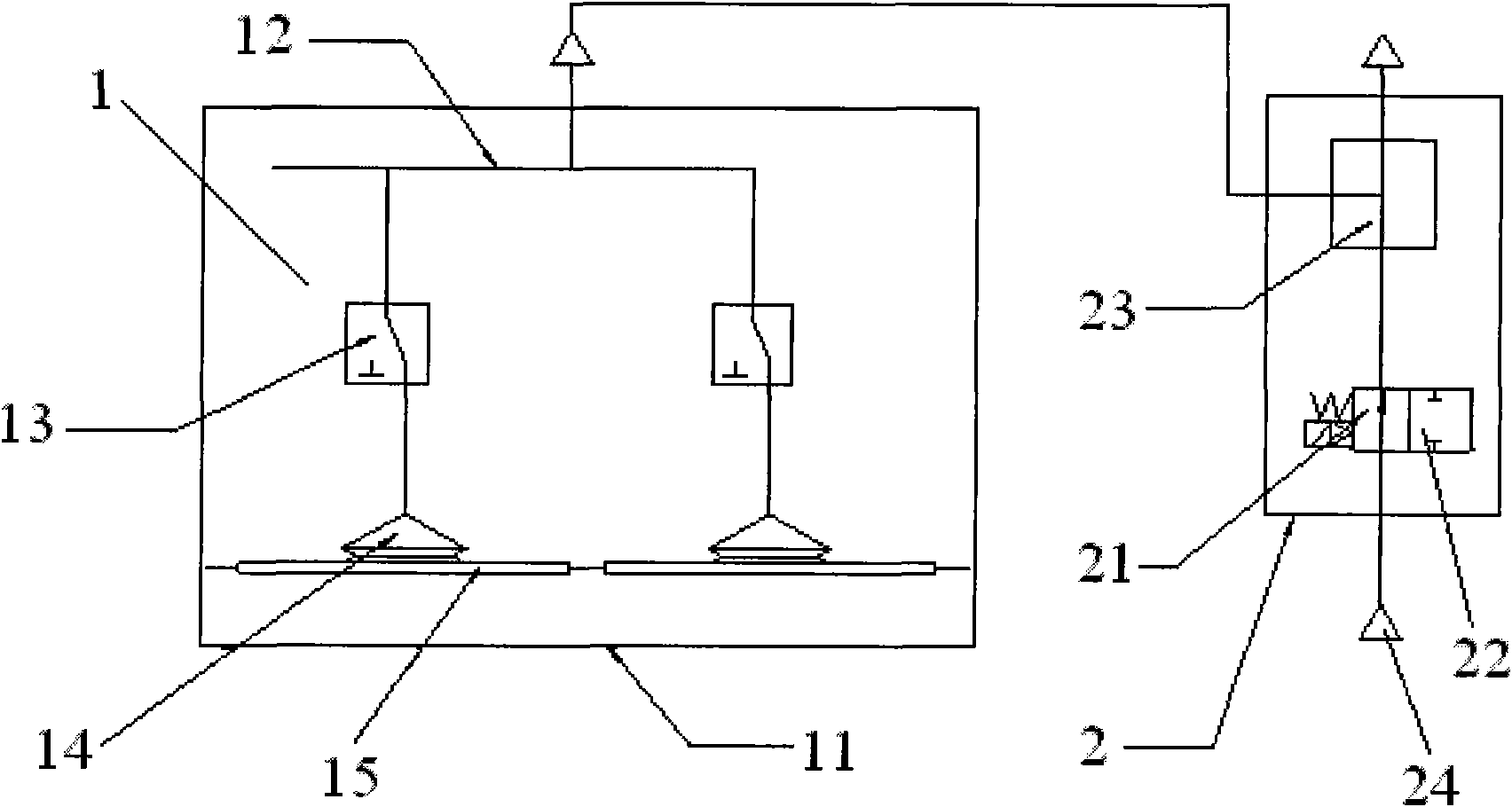

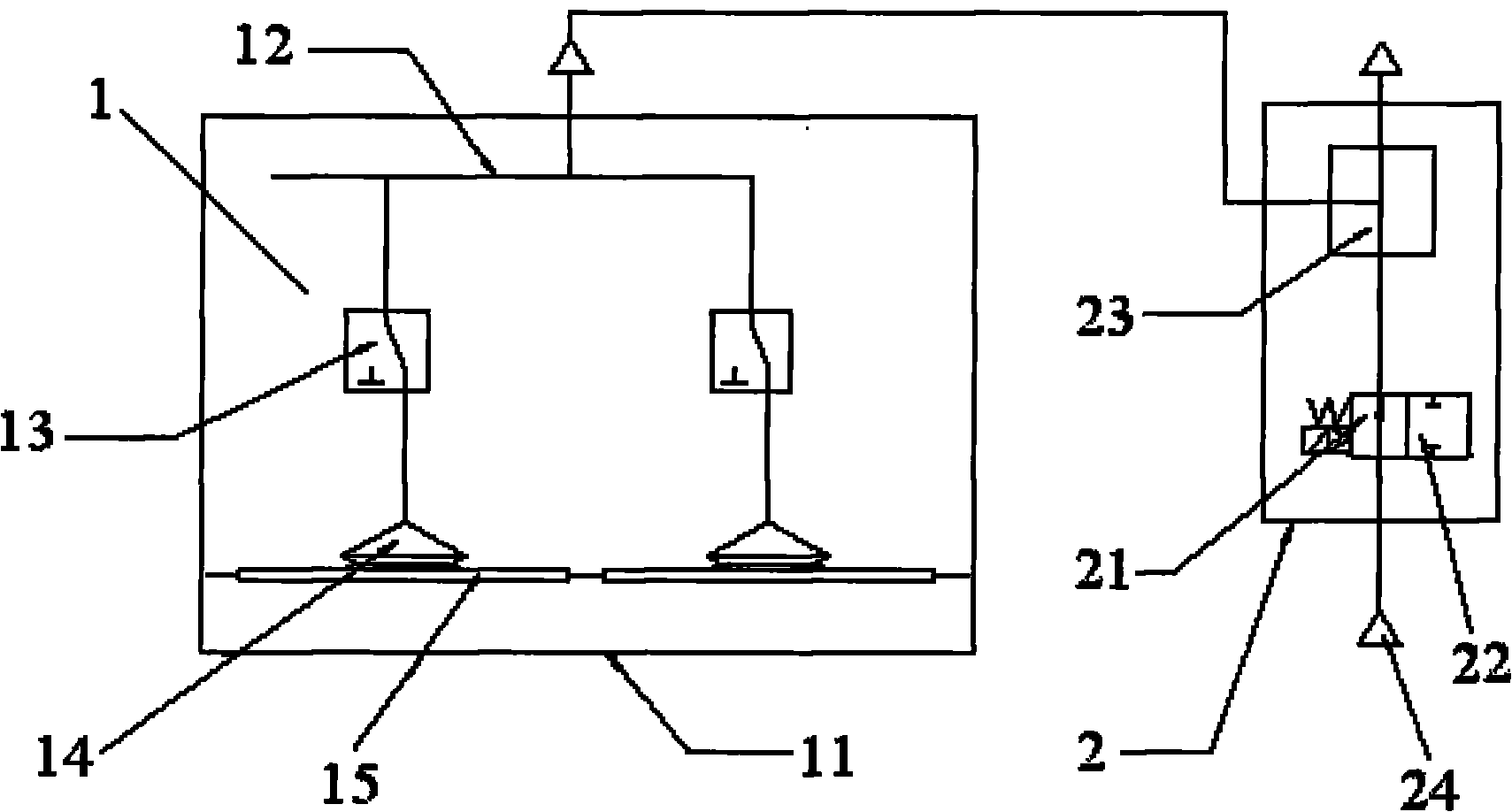

[0016] A solar battery string safety suction cup, its structure is as follows figure 1 As shown, the suction cup device includes a suction cup holder main body 1 and a vacuum controller 2, and the top of the suction cup holder main body 1 is connected to the vacuum generator 23 in the vacuum controller 2 through a pipeline. Suction cup frame main body 1 comprises suction cup device frame body 11, frame body 12, vacuum retainer 13 and suction cup body 14, frame body 12 is located at the top in the suction cup device frame body 11, and vacuum retainer 13 is connected in the bottom of frame body 12, The suction cup body 14 is connected to the lower part of the vacuum holder 13, and a suction cup is provided on the suction cup body 14. The suction cup is a bellows-shaped thin-walled silica gel structure, which can adjust the contact height with the cells and perform flexible contact. The vacuum controller 2 includes a solenoid valve 21, a switch 22 and a vacuum generator 23. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com