Full-automatic bulb lamp

An automatic ball and lamp board technology, applied in the direction of lighting devices, electric light sources, components of lighting devices, etc., can solve the problems of low production efficiency, wire de-soldering, poor reliability, etc., to achieve simple assembly and avoid de-soldering , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to describe the technical content, structural features, and achieved effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

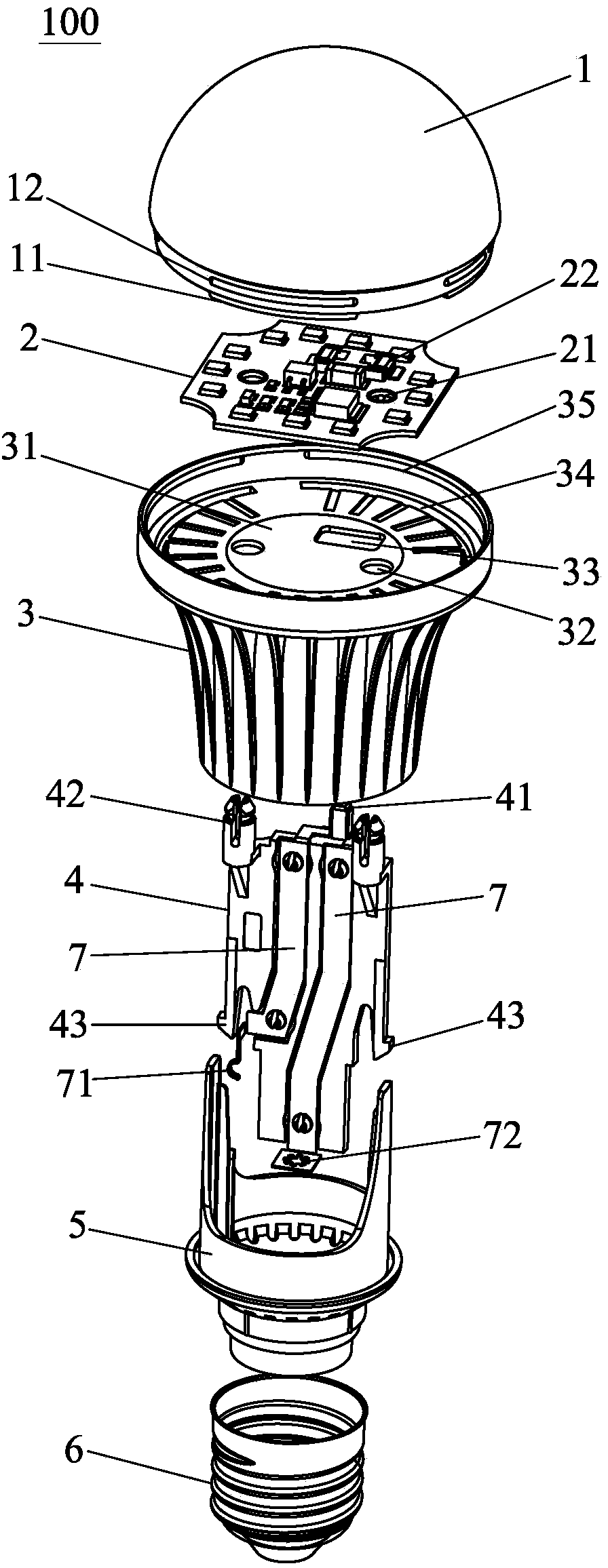

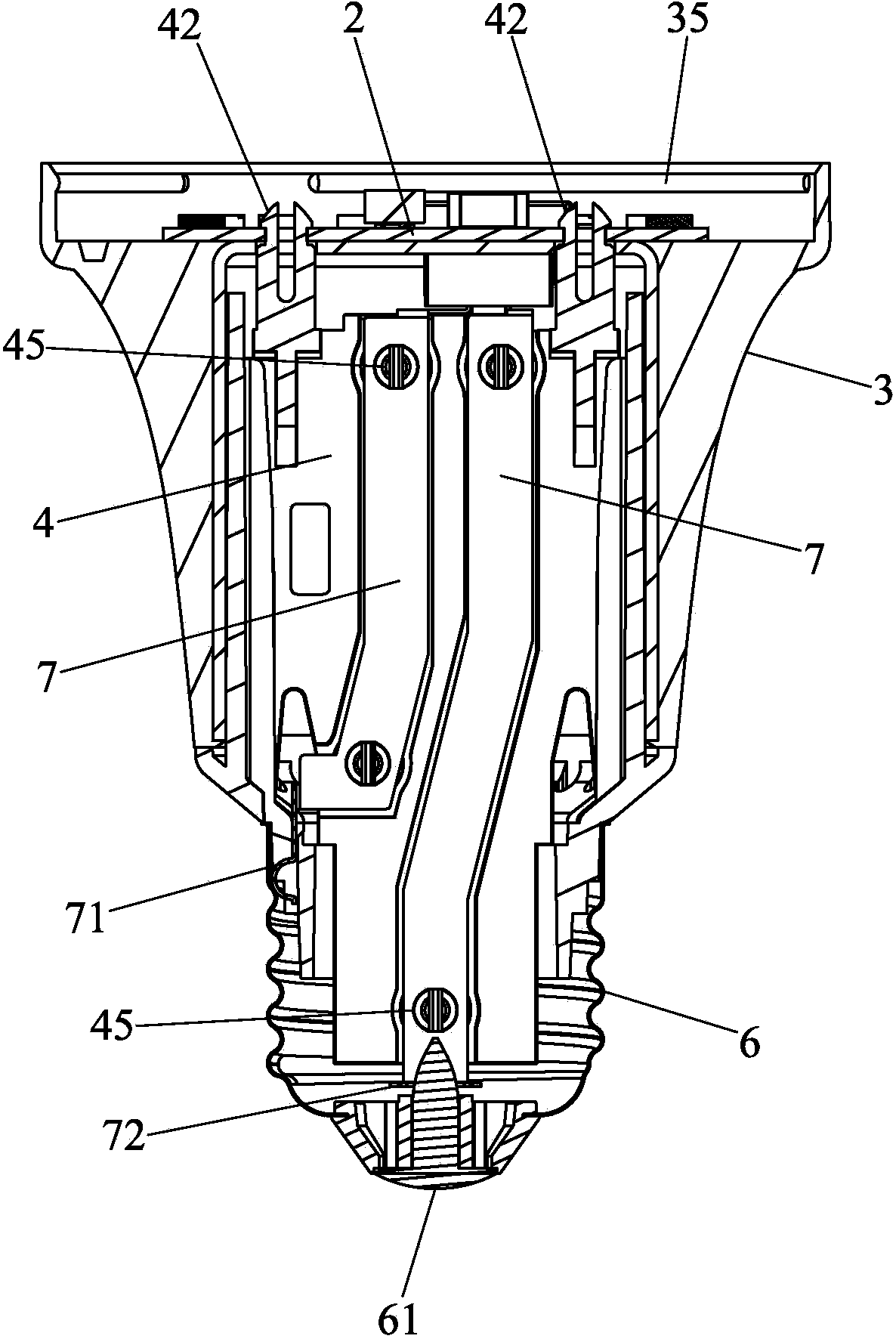

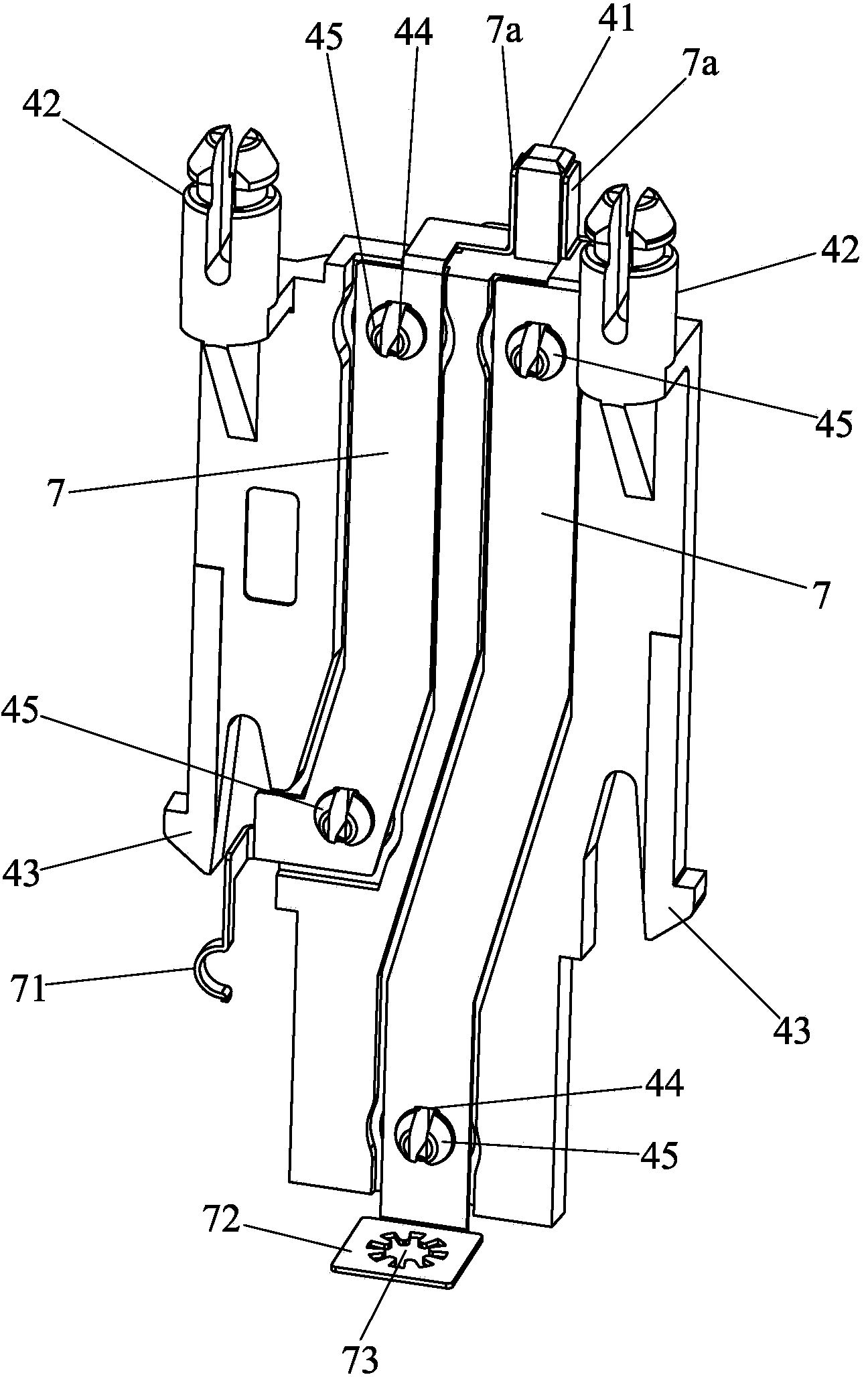

[0022] like Figure 1 to Figure 5 As shown, the fully automated bulb lamp 100 of the present invention includes a lampshade 1, a lamp panel 2, a lamp cup 3, a connector 4, an inner sleeve 5, a lamp cap 6 and two conductive shrapnel 7; the upper end of the connector 4 protrudes upwards for a positioning Column 41, the two conductive elastic pieces 7 are fixed to the connector 4 insulated from each other, and the upper ends of the two conductive elastic pieces 7 are respectively bent upward to form a tongue 7a, and the tongue 7a is positioned on the positioning column 41 on the opposite sides; the connecting piece 4 is fastened in the inner sleeve 5; the lamp cup 3 is provided with a bearing platform 31 for carrying the lamp panel 2, and the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com