PM permanent magnet stepping motor bracket

A technology of motor support and permanent magnet step, which is applied in the direction of casing/cover/support, electrical components, electromechanical devices, etc., can solve the problems of inability to prevent motor shaking, lack of shock absorption buffer, single shock absorption, etc., to achieve Prevent desoldering, fix firmly, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

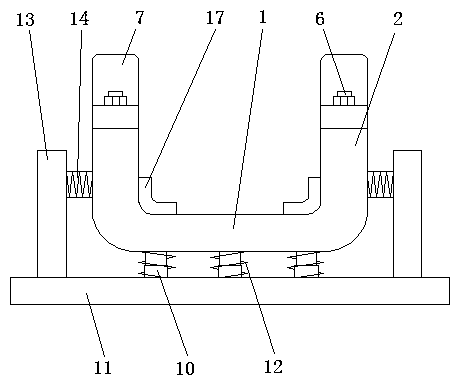

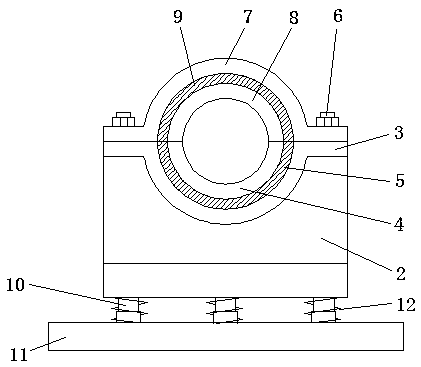

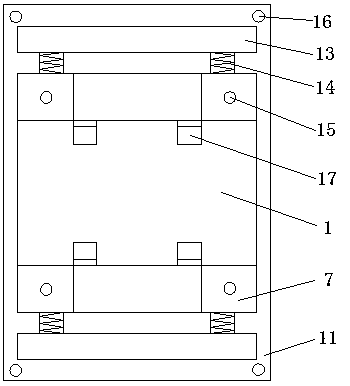

[0018] Such as Figure 1-3 As shown, a PM permanent magnet stepper motor bracket includes a base 1, and side plates 2 are fixedly connected to both ends of the base 1, and a reinforcing rib 17 is fixedly connected to the bottom end of the inner side of the side plate 2, and the reinforcing rib 17 The bottom is fixedly connected to the top of the base 1, which can improve the structural strength of the base 1 and the side plate 2. The top of the side plate 2 is fixedly connected with a lower limit clip 3, and the outer side of the inner cavity of the lower limit clip 3 is fixedly connected. There is an arc-shaped sidewall one 4, and the inner side of the arc-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com