Method for winding multi-pole-piece lithium battery winding core

A lithium battery, battery roll technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems such as long distance is not conducive to welding, two roll cores are overlapped and easily dislocated, and the quality is different.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A winding method for a multi-pole sheet lithium battery winding core, comprising the following steps,

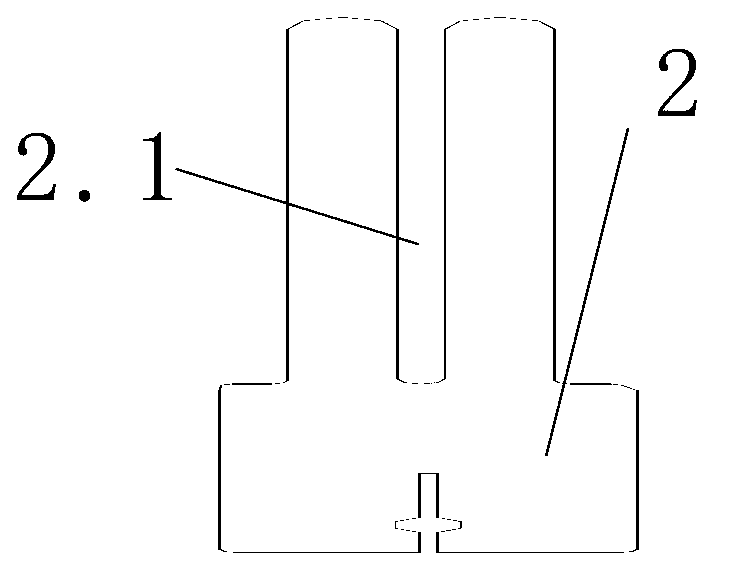

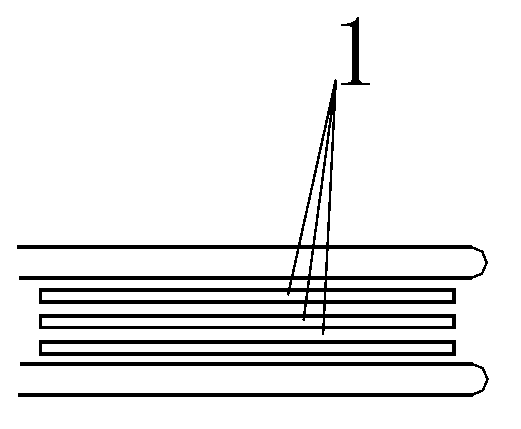

[0037] 1) Completely overlap the three diaphragms (1), and pass the overlapped diaphragm (1) through the middle gap (2.1) of the U-shaped needle (2), as figure 2 shown.

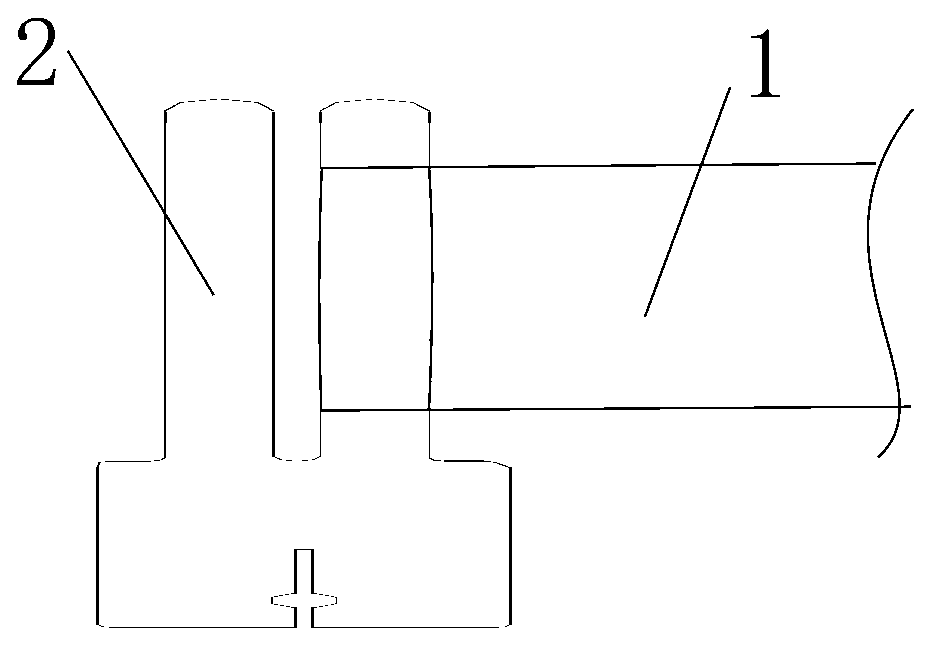

[0038] The overlapped diaphragm (1) is tightened on one side of the U-shaped coil needle (2), and folded in half by hand to tighten, as in image 3 shown.

[0039] Turn on the switch of the winding machine, and the U-shaped winding needle (2) rotates half a circle, such as Figure 4 shown.

[0040] 2) Insert the first positive electrode sheet (3) between the first layer of separator and the second layer of separator, the tab (3.1) of the first positive electrode sheet (3) is exposed, and the U-shaped needle (2) rotates half a circle; Such as Figure 5 shown.

[0041] 3) Insert the first negative electrode sheet (4) between the second layer of separator and the third layer of separator, the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com