Solar cell luminescent plate and manufacture method therefor

A technology of solar cells and solar cells, which is applied in the direction of electric light sources, semiconductor devices of light-emitting elements, circuits, etc., can solve problems such as inconvenient detection, reverse electrode installation, and desoldering of wires, so as to improve reliability and production efficiency. Reduce the difficulty of assembly and avoid the effect of false welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

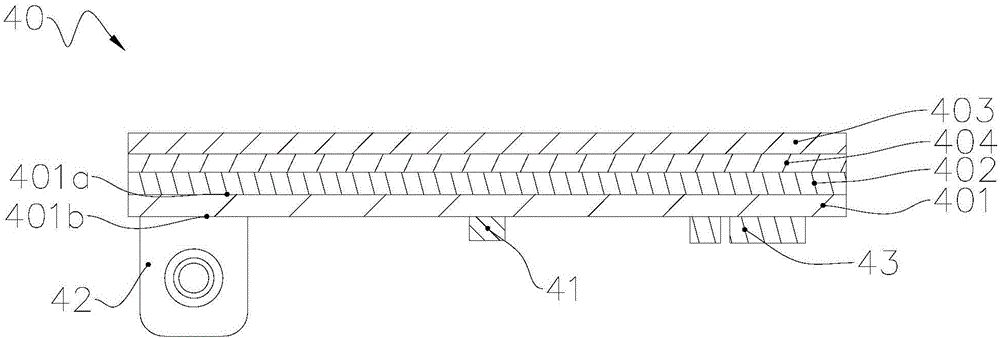

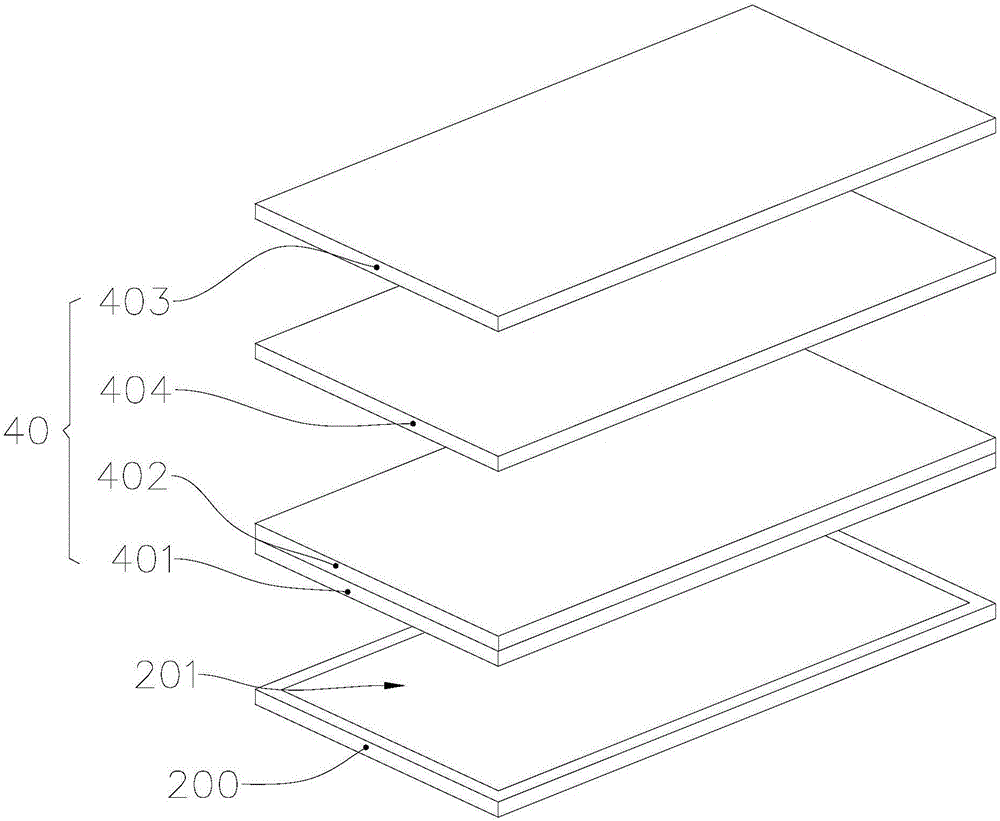

[0042] Such as figure 1 and 2 As shown, in this embodiment, polycrystalline silicon solar cells or traditional monocrystalline silicon solar cells are used as an example to illustrate the production of solar cell light-emitting panels 40. It should be noted that the traditional monocrystalline silicon solar cells referred to here are Refers to monocrystalline silicon solar cells other than those produced by Sunpower.

[0043] 1. Fabrication of the circuit substrate 401 , the circuit substrate 401 of this embodiment is a single-sided board.

[0044] In this embodiment, the circuit substrate 401 has a front side (ie, the first surface 401a in the figure, hereinafter referred to as the first surface 401a) and a back side (ie, the second surface 401b in the figure, hereinafter generally referred to as the second surface 401b), Print solder resist ink (not shown) on the second surface 401b to form pad positions (not shown), bake and solidify to obtain a circuit substrate 401 with...

Embodiment 2

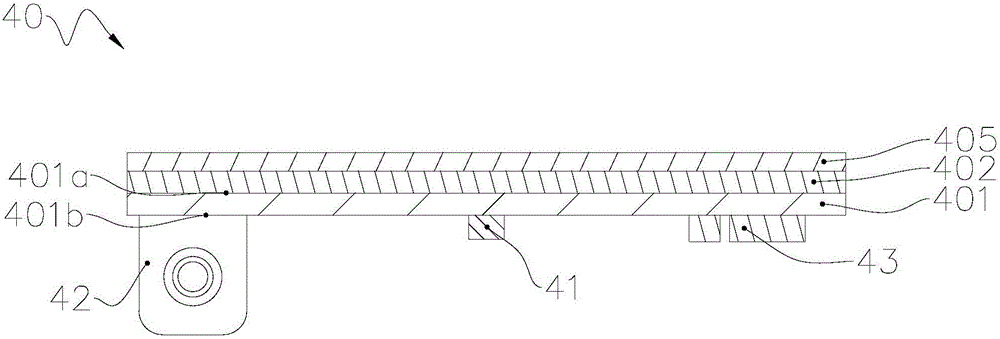

[0052] Attached below image 3 and 4 , only the differences from Embodiment 1 will be described in detail.

[0053] Such as image 3 and 4 As shown, in this embodiment, the fabrication of the solar cell light-emitting panel 40 is described by taking the Sunpower monocrystalline silicon cell as an example.

[0054] 1. Fabrication of the circuit substrate 401 , the circuit substrate 401 of this embodiment is double-sided.

[0055] In this embodiment, the circuit substrate 401 prints solder resist ink (not shown) on both the first surface 401a and the second surface 401b to form pad positions, and after baking and curing, a patterned circuit layer is obtained on both surfaces ( not shown in the figure) circuit substrate 401. This process is well known to those skilled in the art and will not be described in detail here.

[0056] 2. Packaging of electronic components including LEDs.

[0057] For the pad position of the circuit substrate 401, use a stencil printing solder pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com