Angle steel welding fixture

A technology of welding fixture and angle steel, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of short service life of the cage, gaps in the welding place, and weak welding, etc., so as to avoid desoldering, The effect of firm welding, improving welding efficiency and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

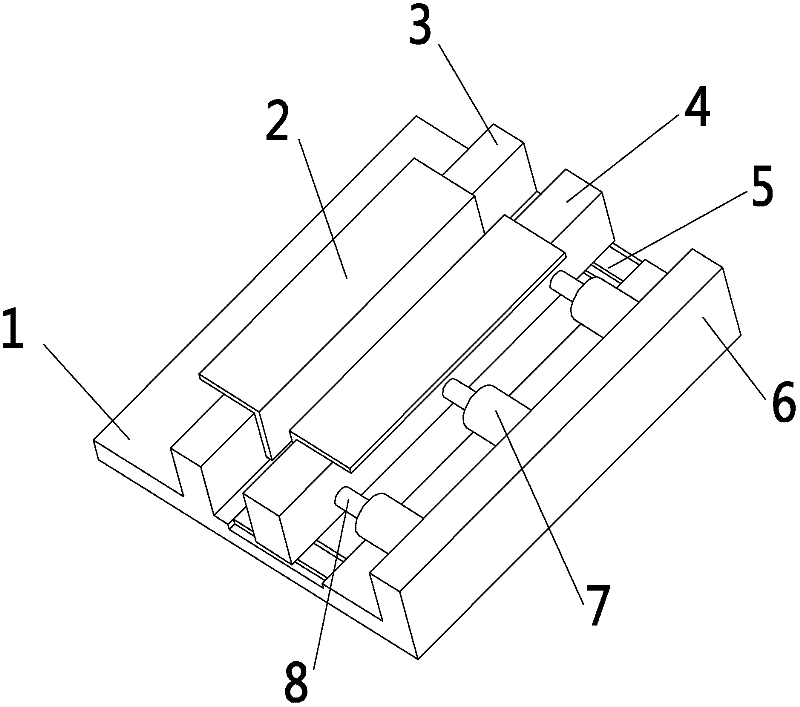

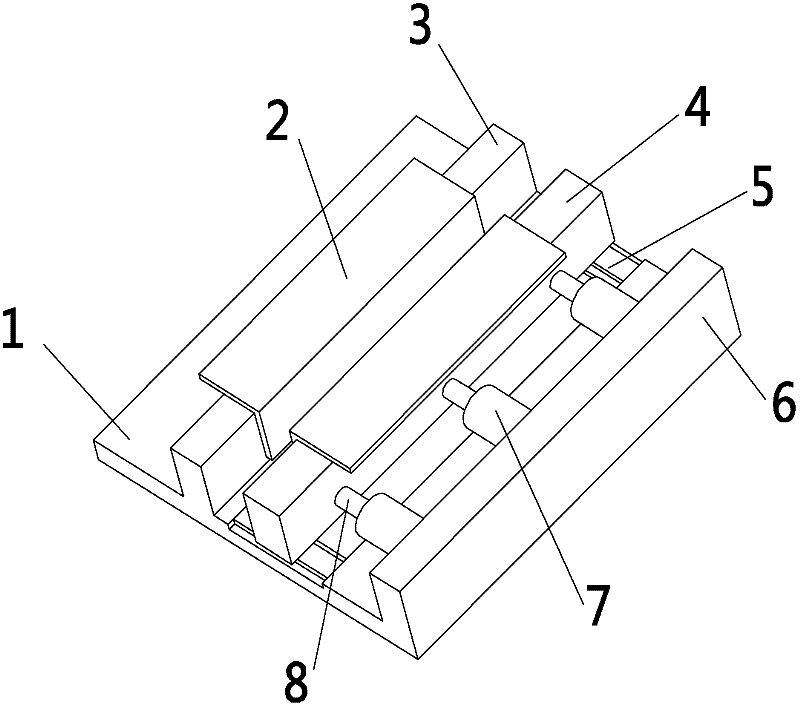

[0014] attached figure 1 It is an angle steel welding fixture according to the present invention, comprising a base 1, a fixed plate 4 and a cylinder 7; the base 1 is a rectangular plate, and a positioning plate 3 and a baffle plate 6 are fixed above the base 1; the positioning Plate 3 is located at the front end of base 1, and baffle plate 6 is located at the rear end of base 1; Said fixed plate 4 is located between positioning plate 3 and baffle plate 6, and fixed plate 4 can move back and forth on base 1; Said base 1 On the position where the fixed plate 4 moves, there is a slide rail 5; the fixed plate 4 slides on the slide rail 5; the cylinder 7 is fixed on the base 1, and is located between the fixed plate 4 and the baffle plate 6 There are three cylinders 7, which are respectively located at the left end, the right end and the middle of the fixed plate 4; the spacing of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com