LED (light-emitting diode) bulb

A technology for LED bulbs and LED power sources, applied in lighting devices, light sources, electric light sources, etc., can solve the problems of complex structure and assembly process, failure of LED lights, easy to produce virtual welding, etc., to achieve simple structure, prevent pin de-soldering, Assemble the effect of quick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

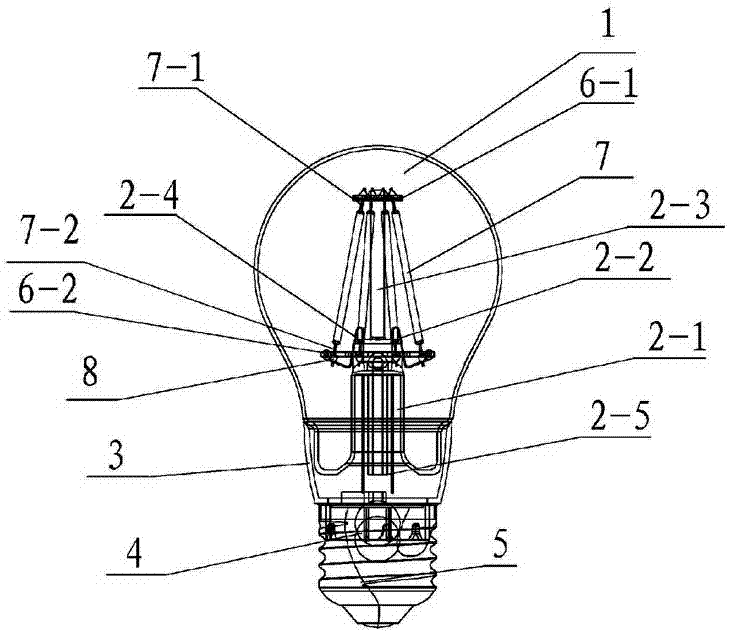

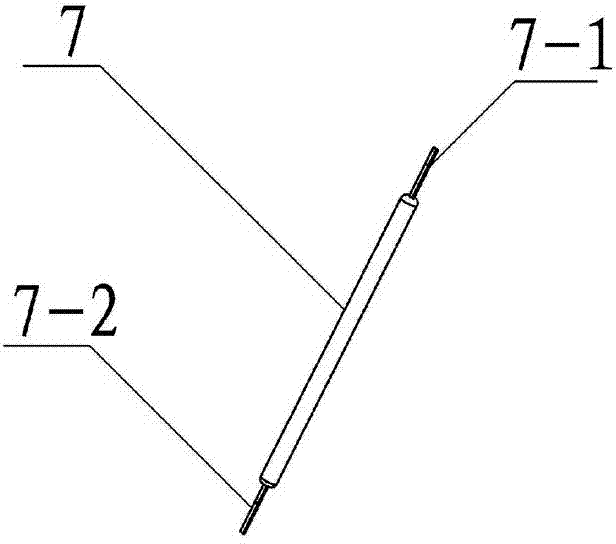

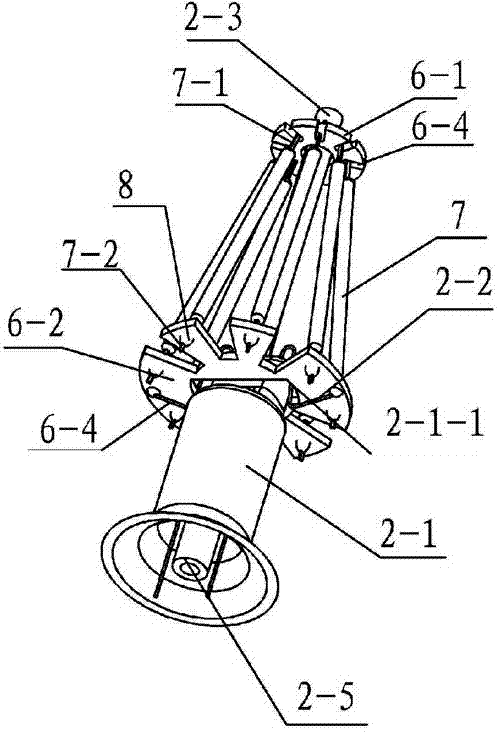

[0016] see Figure 1-Figure 5 As shown, an LED light bulb includes a bulb shell 1, a stem, a plastic shell 3, an LED power supply 4, a lamp cap 5, a first circuit board 6-1, a second circuit board 6-2, and a set of insulated central fixed cylinders 2-3 composition. LED light strip 7, the LED power supply 4 is installed in the cavity of the plastic casing 3, the input ends of the LED power supply 4 are respectively connected to the two AC electrodes of the lamp holder 5, and the two ends of the LED light strip 7 are respectively provided with upper pins 7-1 and the lower pin 7-2, the shape, size, internal structure, and electrical parameters of each LED light strip 7 are consistent, and the stem is composed of a base 2-1 and an exhaust pipe 2-5. Between the bulb 1 and the stem is a vacuum-sealed cavity filled with high thermal conductivity gases such as helium and nitrogen. The top of the base 2-1 is a long boss 2-1-1, and an insulating central fixed cylinder 2-3 extends upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com