Enhanced sinking roll

A sunken roller and reinforced technology, which is applied in the direction of coating, metal material coating process, hot-dip plating process, etc., can solve the problems of shortened service life, poor intermediate strength, easy deformation, etc., to improve bending strength, flow The effect of small resistance and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

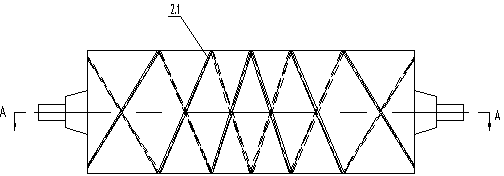

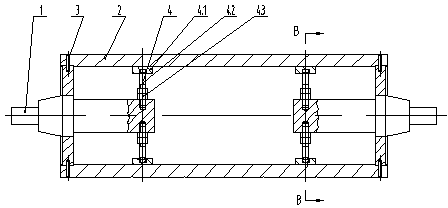

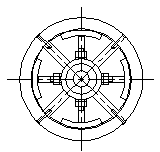

[0019] The reinforced sinking roller shown in the accompanying drawings includes a roller 2 and a roller shaft 1 welded and fixed at both ends; a support structure 4 is provided on the roller shaft 1 extending into the interior of the roller 2; there are two support structures 4, which are respectively arranged On the roller shaft 1 that extends into the inside of the roller 2 at both ends; the support structure 4 is an adjustable support, including a support block 4.1, a screw rod 4.2 and a nut 4.3; the support block 4.1 is an arc block, and its outer arc is in line with the roller 2 The curvature of the inner wall is the same; one end of the screw 4.2 is fixedly connected to the outer wall of the roller shaft 1 through the nut 4.3; the other end is floatingly connected to the support block 4.1, and the support block 4.1 is supported on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com