Semi-independent rear suspension of automobile torsion beam

A torsion beam, semi-independent technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of waste of cost and time, complex force of torsion bar, high maintenance cost, etc., to avoid desoldering, simple processing, The effect of guaranteeing the life of the stent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

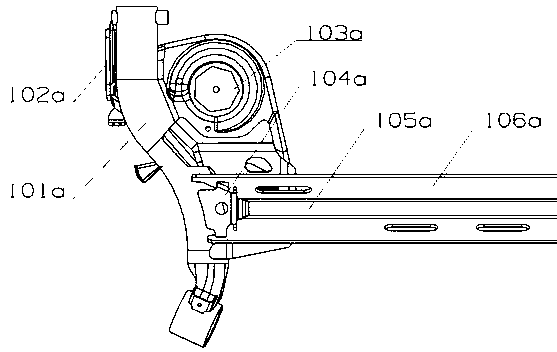

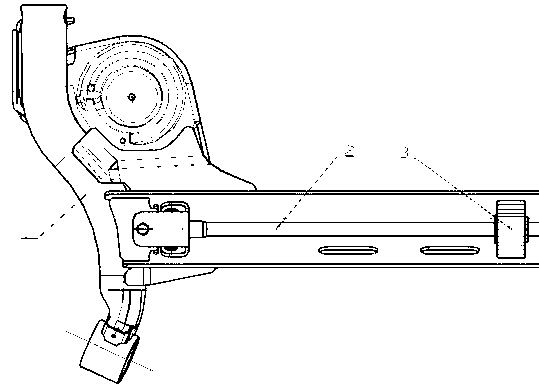

[0032] An automobile torsion beam semi-independent rear suspension, such as figure 2 As shown, the semi-independent rear suspension of the automobile torsion beam is a detachable structure, including a torsion beam welded part 1, a torsion bar welded part 2 and a torsion bar stabilizer 3;

[0033] The torsion beam welded part 1 includes a beam 105, a longitudinal arm 101 at both ends of the beam, a hub bracket 102, and a spring seat 103. The ends of the two ends of the beam are respectively provided with two holes and connected with a beam reinforcement plate 4. The beam, The longitudinal arms, the wheel hub brackets, the spring seats and the beam reinforcement plates at both ends of the beam are connected into one body by welding, wherein the beam reinforcement plates 104 are fixed with welding nuts;

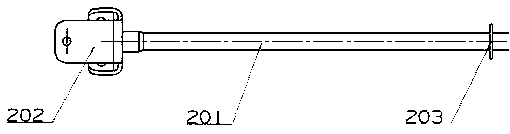

[0034] The torsion bar weldment 2 includes a torsion bar 201, a torsion bar bracket 202 located at both ends of the torsion bar 201 and two pads 203 located in the middle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com