Universal cooler for efficiently removing oily water

A technology of dirty oil water and radiators, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., and can solve the problems of low heat transfer efficiency between radiator fins and radiator tubes, poor connection reliability of radiator fins, and low heat dissipation performance and other issues to achieve the effect of avoiding displacement, uniform distribution, and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

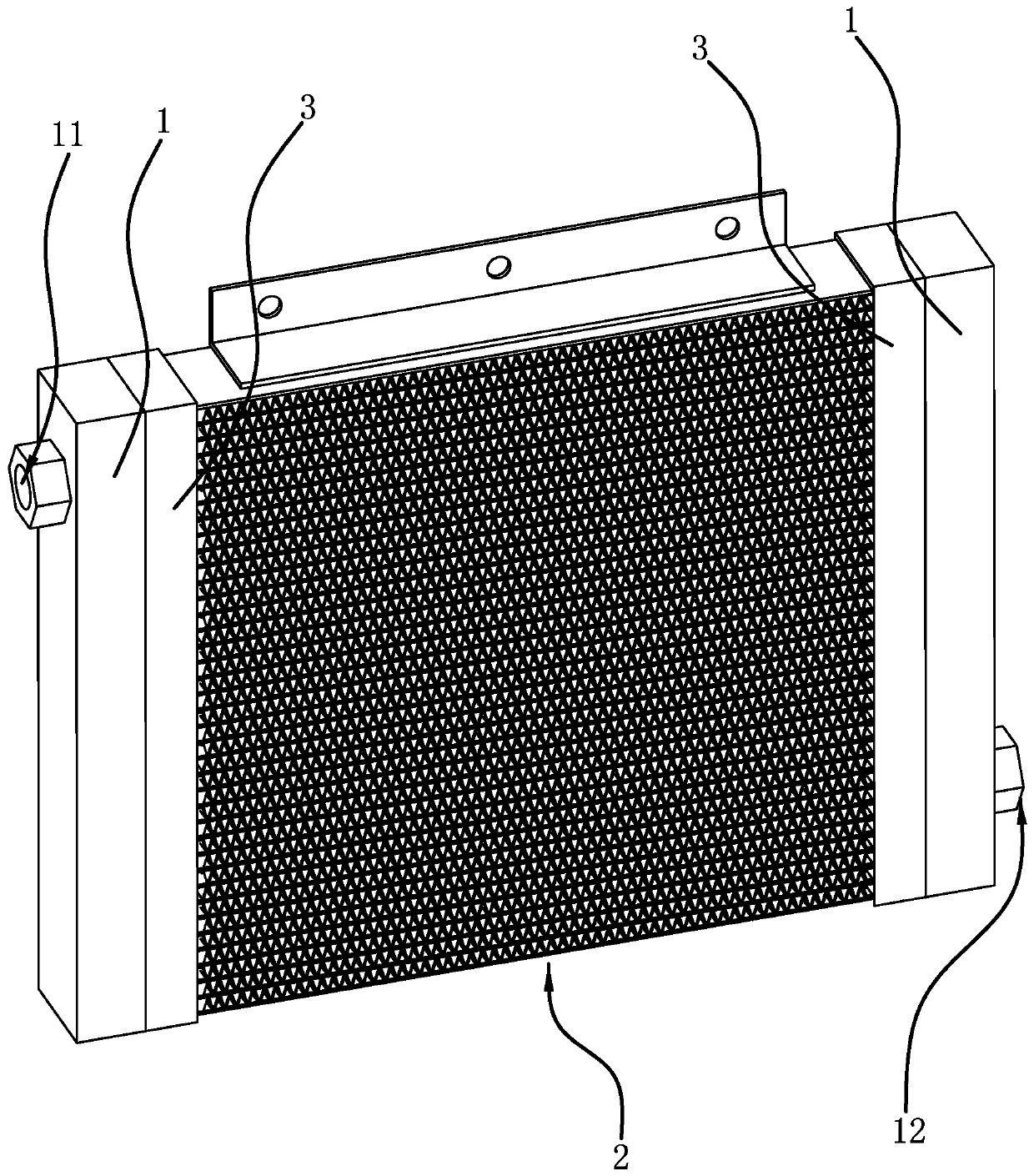

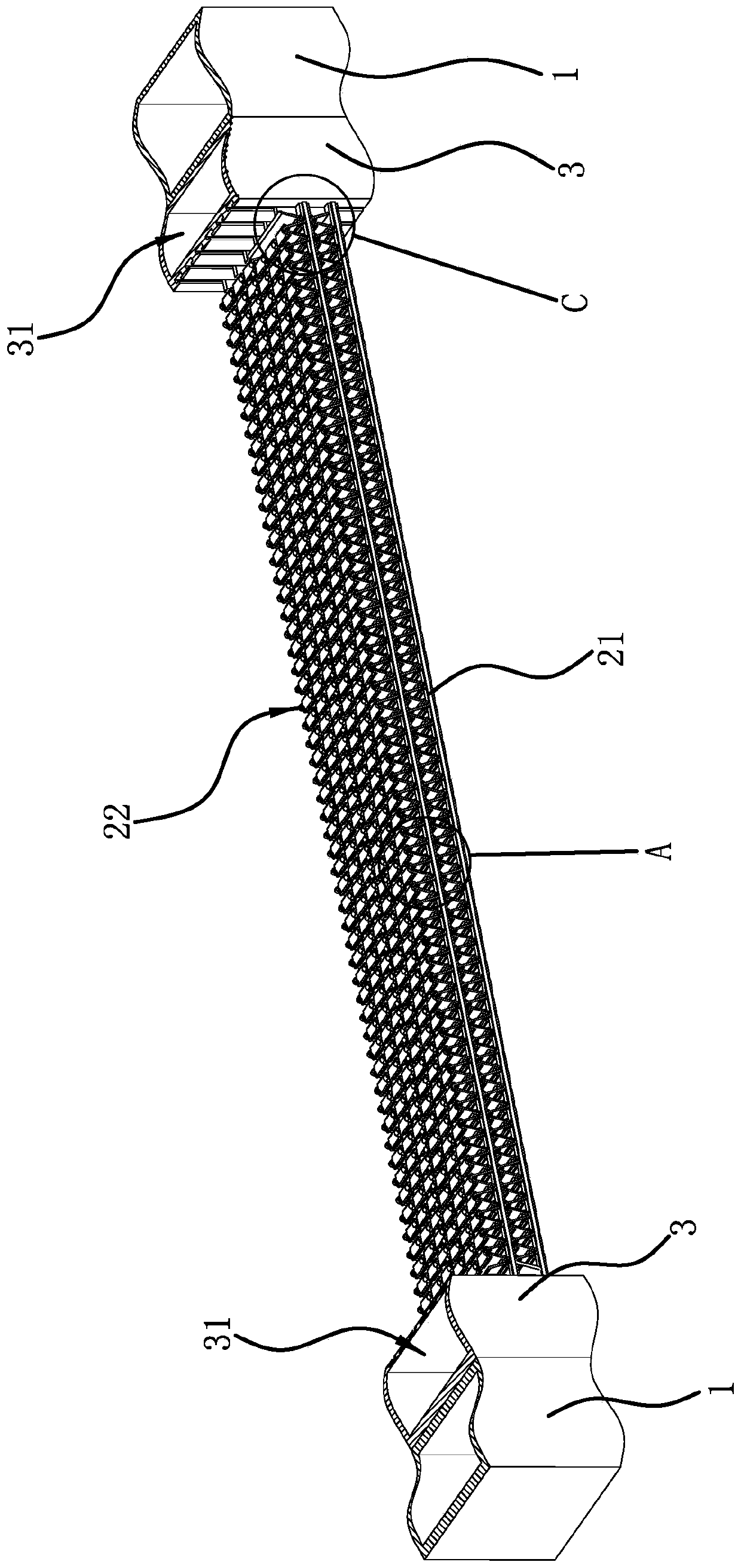

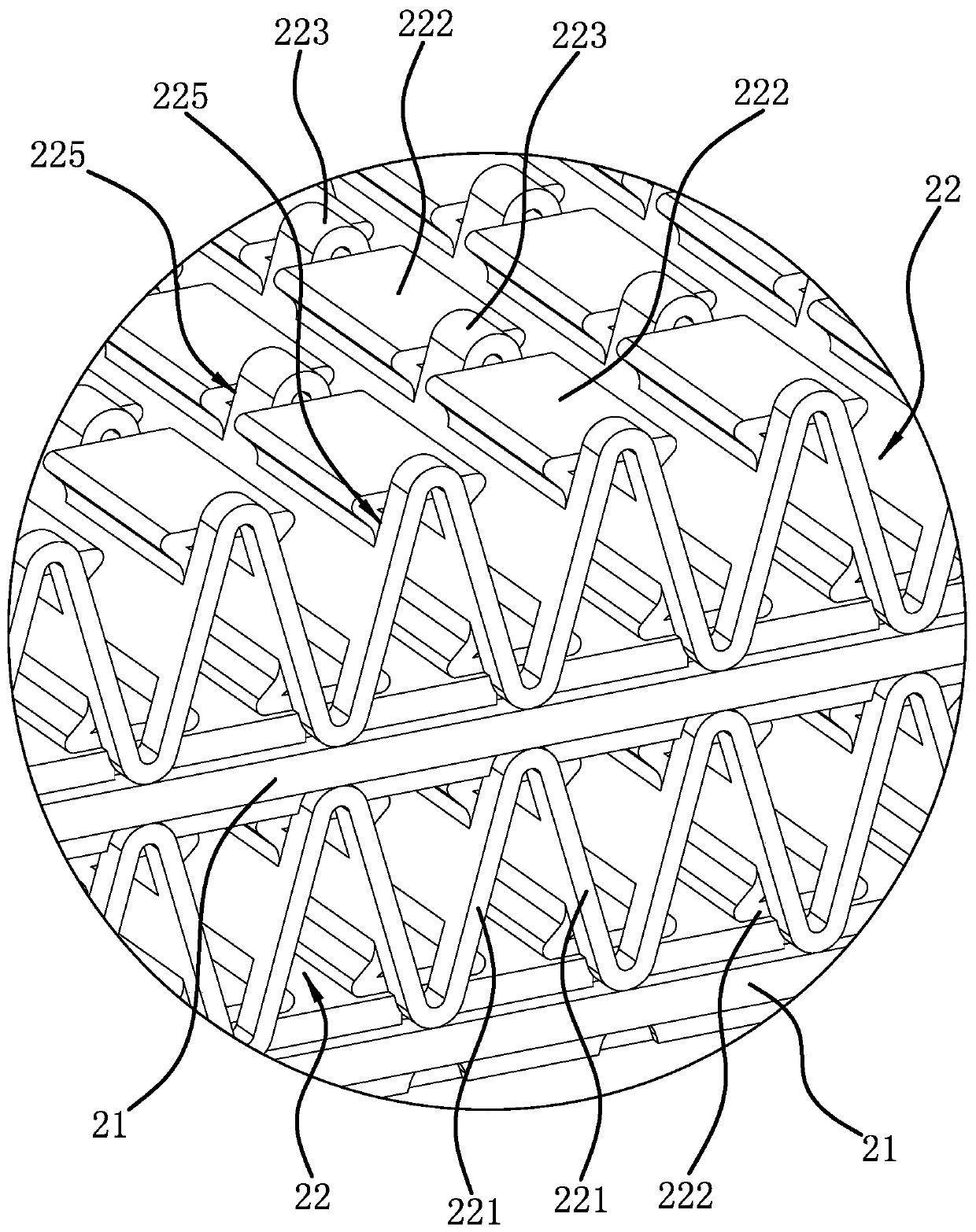

[0032] Such as figure 1 As shown, a high-efficiency decontamination oil-water universal radiator includes two oil chambers 1 and a core 2 between the two oil chambers 1, one of which is provided with an oil inlet 11, and the other oil chamber 1 is provided with a There is an oil outlet 12, combined with figure 2 , image 3 As shown, the core body 2 includes a number of heat dissipation pipes 21 arranged up and down in sequence, and the two ends of the heat dissipation pipes 21 are respectively connected with the two oil chambers 1, and two long strips are arranged between the adjacent two heat dissipation pipes 21 along the length direction. radiating fins 22, and the two radiating fins 22 are arranged along the width d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com