Preparation process of modified plastic particles

A technology of plastic particles and preparation process, which is applied in the direction of coating, etc., can solve the problems of uneven drying, high temperature and damage of modified plastic particles, and achieve the effect of improving drying efficiency, improving efficiency, and improving contact efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

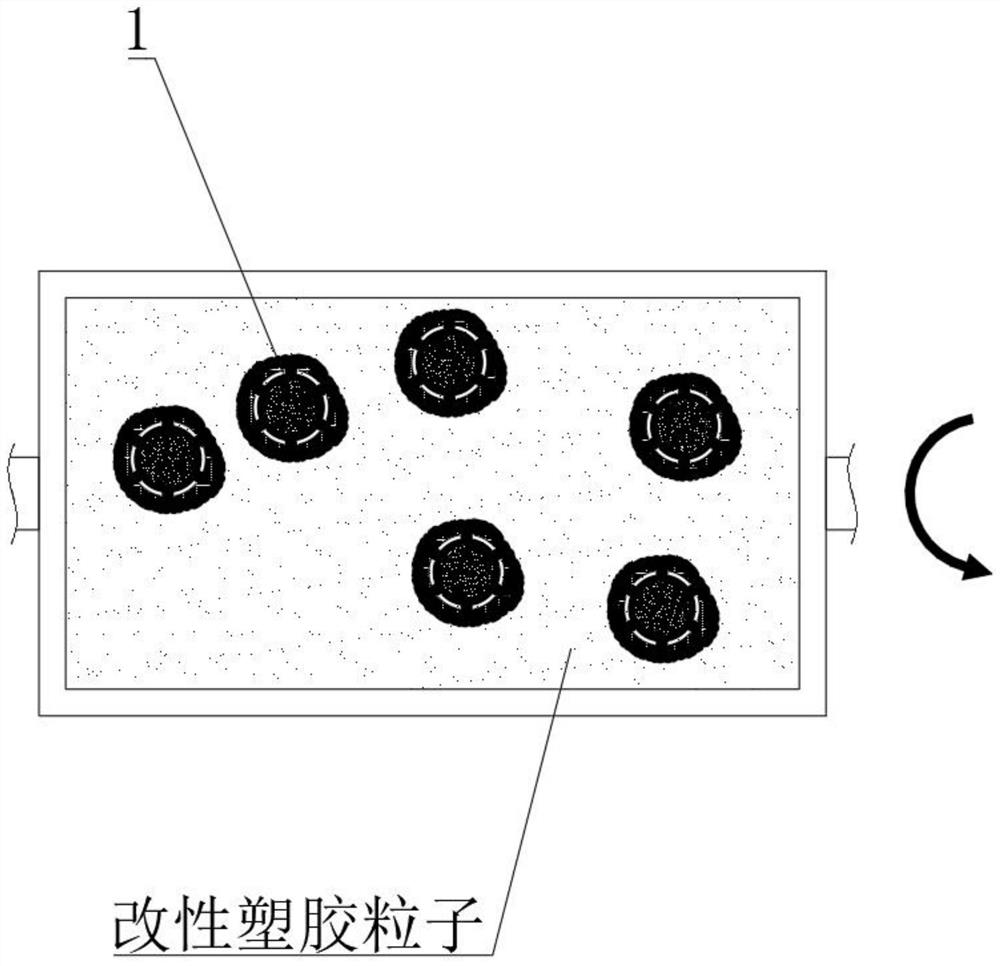

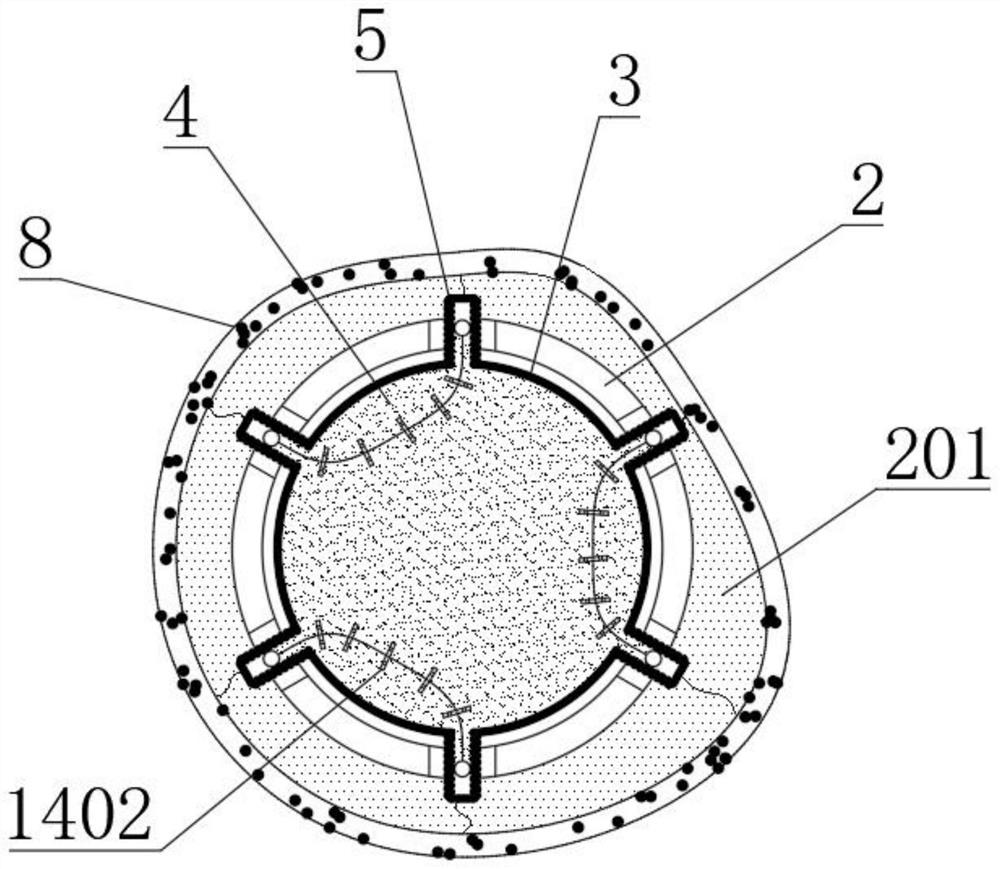

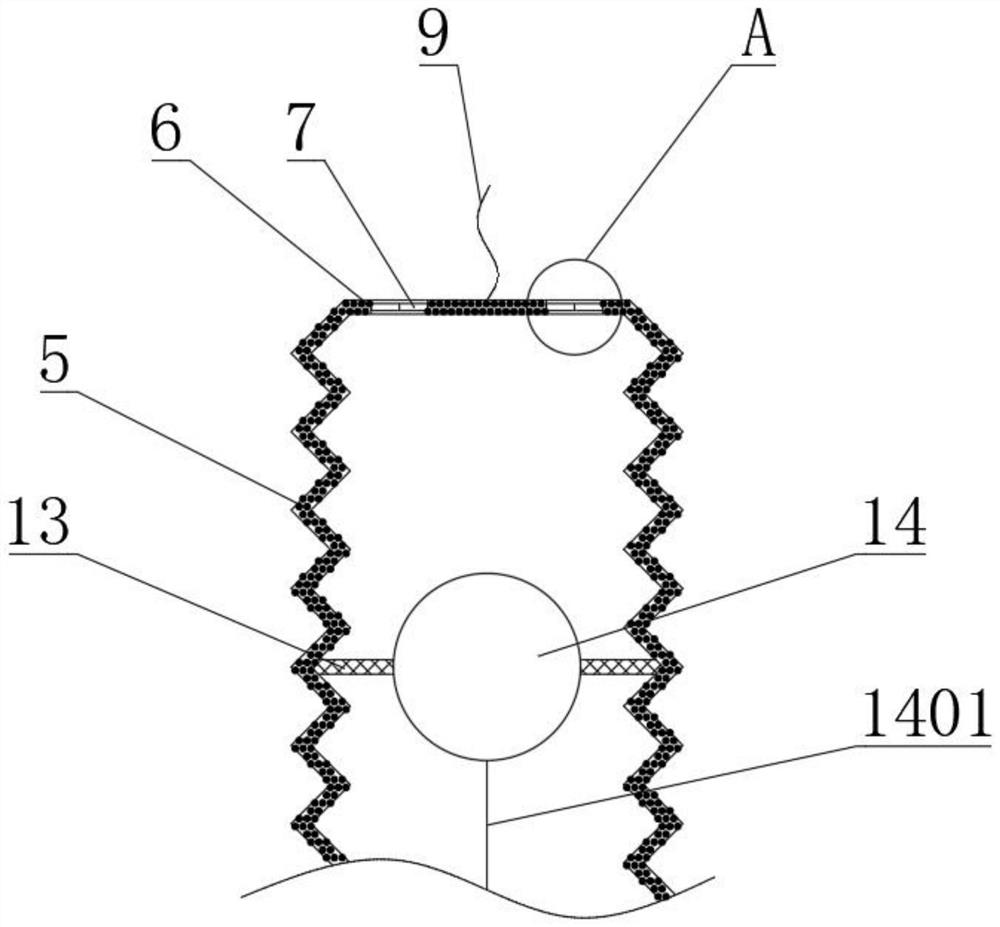

[0041] see figure 1 , a preparation process of modified plastic particles, comprising the following steps:

[0042] S1. Put antistatic agent, antiaging agent, release agent, toughening agent, glass fiber, silicone powder, sodium carboxymethyl cellulose, and talc into the mixer for low-speed mixing, mix for 3-8 minutes and add ASA Rubber powder, then mix at high speed for 5-10 minutes;

[0043] S2. Transport the mixed material to the twin-screw extruder through the pipeline for shearing, plasticizing and extruding, and use the water circulation cooling system to water-cool the strips. The water-cooling temperature is 30-39°C, and the obtained plastic strips are transported to the traction pelletizer. , the speed of the granulator is 600-900rpm, thus forming wet plastic particles;

[0044] S3. Add wet plastic particles into the drying cylinder, add auxiliary drying balls 1 inside, and rotate the drying cylinder while heating the drying cylinder, so as to complete the drying of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com