Induction duct-desoldering device and desoldering method

A technology of desoldering and conduit, applied in the direction of electric heating devices, welding equipment, metal processing equipment, etc., can solve the problems of high heating temperature, poor brazing quality, uneven heating, etc., achieve uniform heating and improve welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

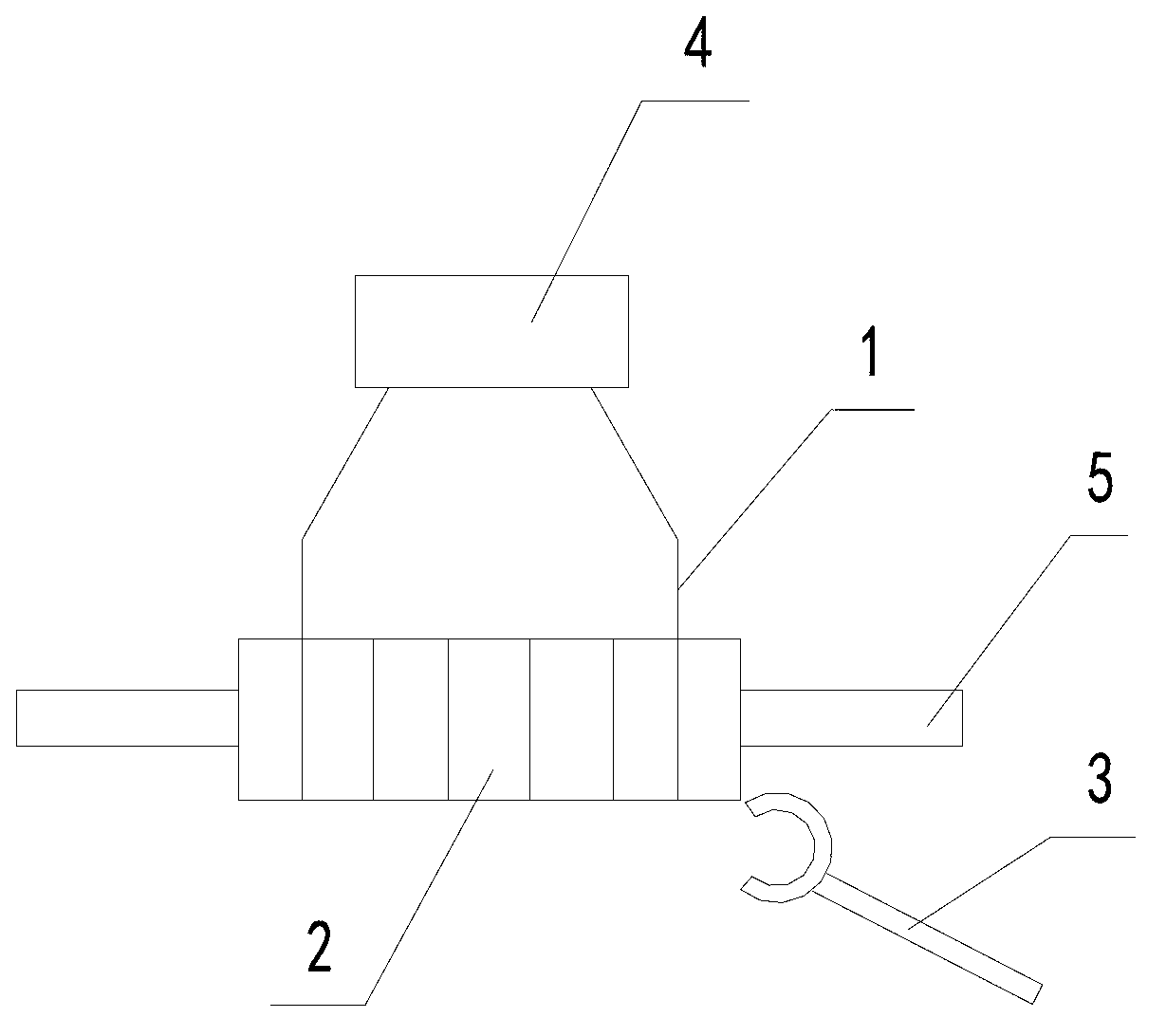

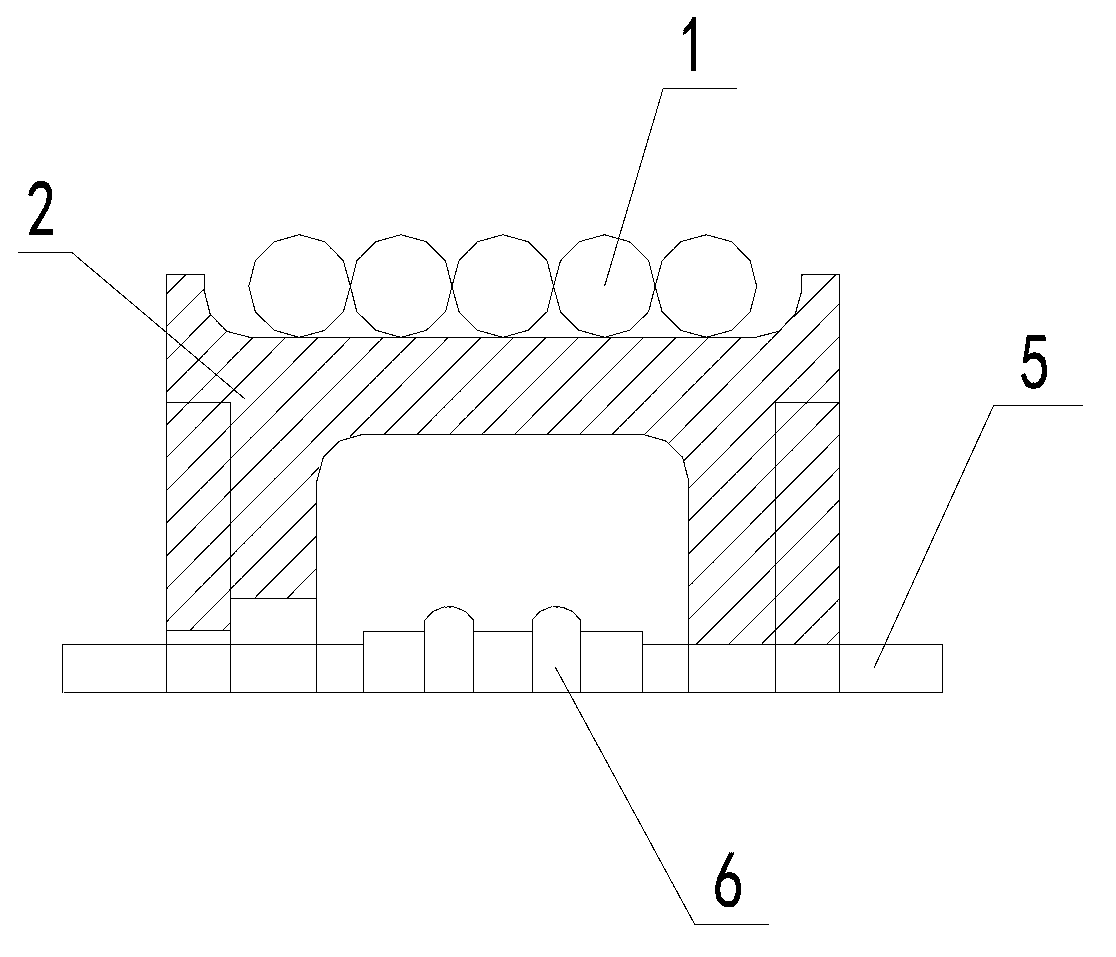

[0017] Such as figure 1 , figure 2 , a catheter induction desoldering device, which includes an induction coil 1, an induction power supply 4, a protective copper sleeve 2 and a dismantling pliers 3 matched with the protective copper sleeve 2, the induction coil 1 is wound on the protective copper sleeve 2, the induction coil 1 and the induction power supply 4 connections.

[0018] The induction coil 1 is a water-cooled induction coil.

[0019] The desoldering method of the catheter induction desoldering device, it comprises the following steps:

[0020] (1) Install the protective copper sleeve 2 at the position of the bushing 6 on the conduit 5 that needs to be desoldered;

[0021] (2) Wind the induction coil 1 on the protective copper sleeve 2;

[0022] (3) Connect the induction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com