Desoldering device, system and method for through-hole component

A component and heating device technology, which is applied in the field of through-hole component desoldering devices, can solve the problems of low success rate and efficiency of desoldering, pad damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

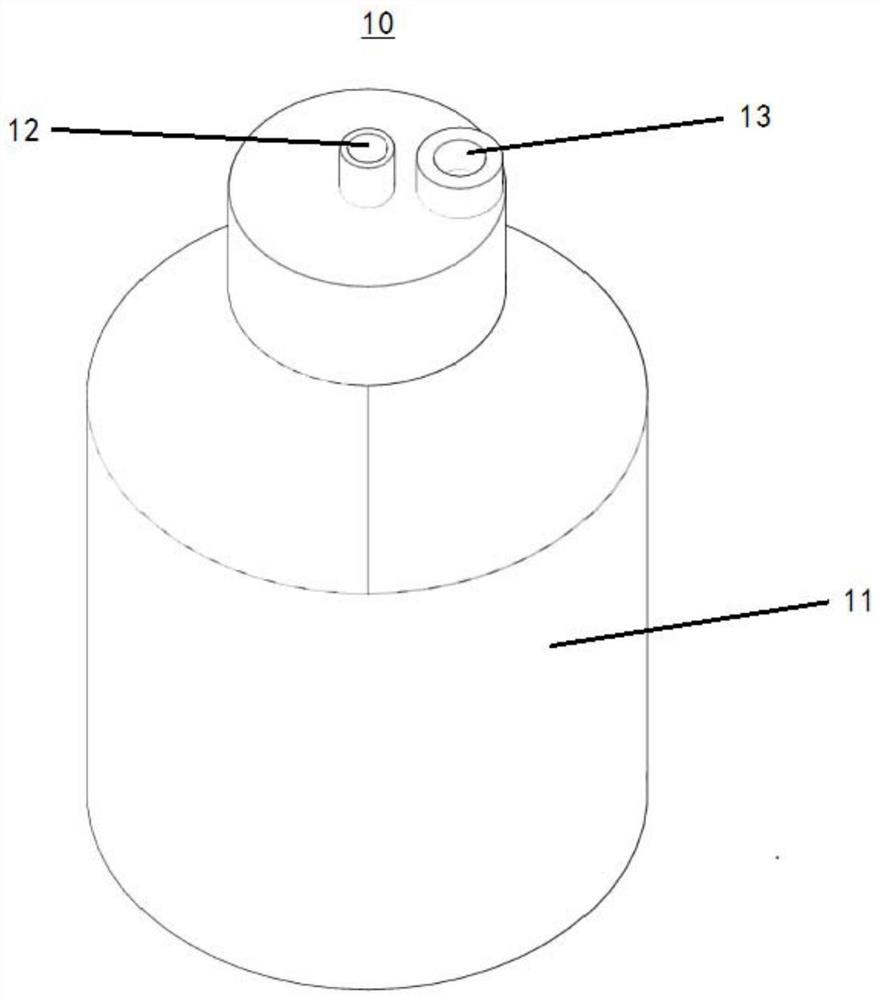

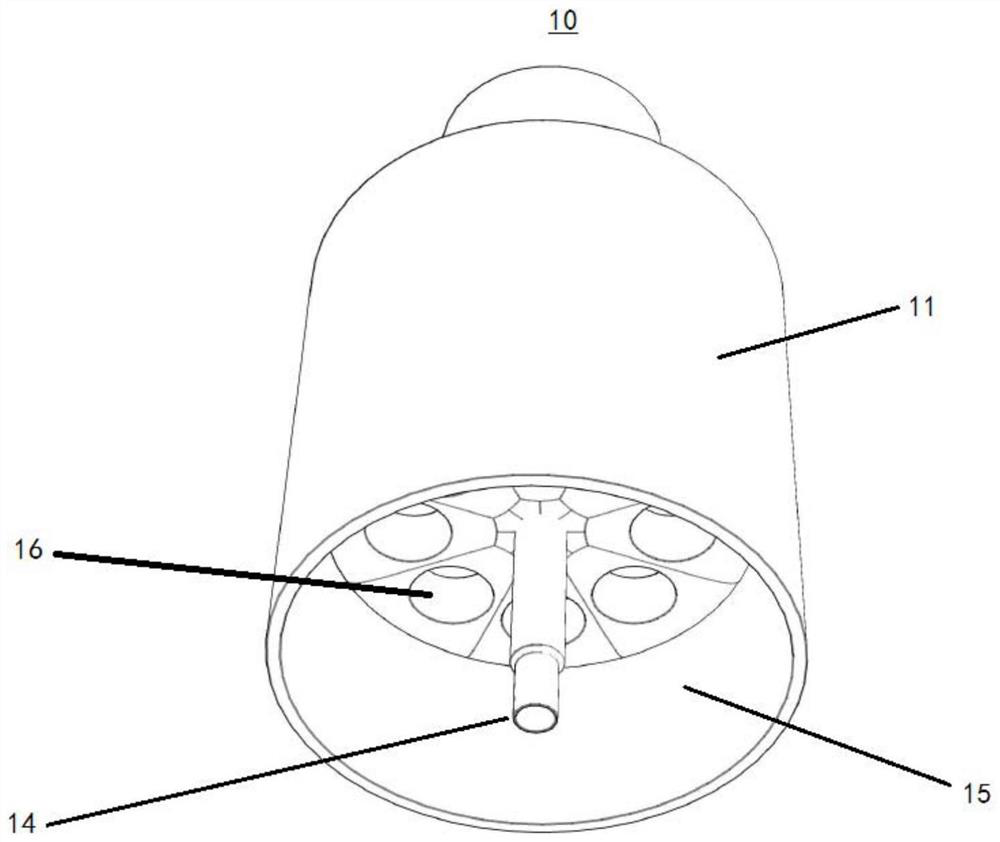

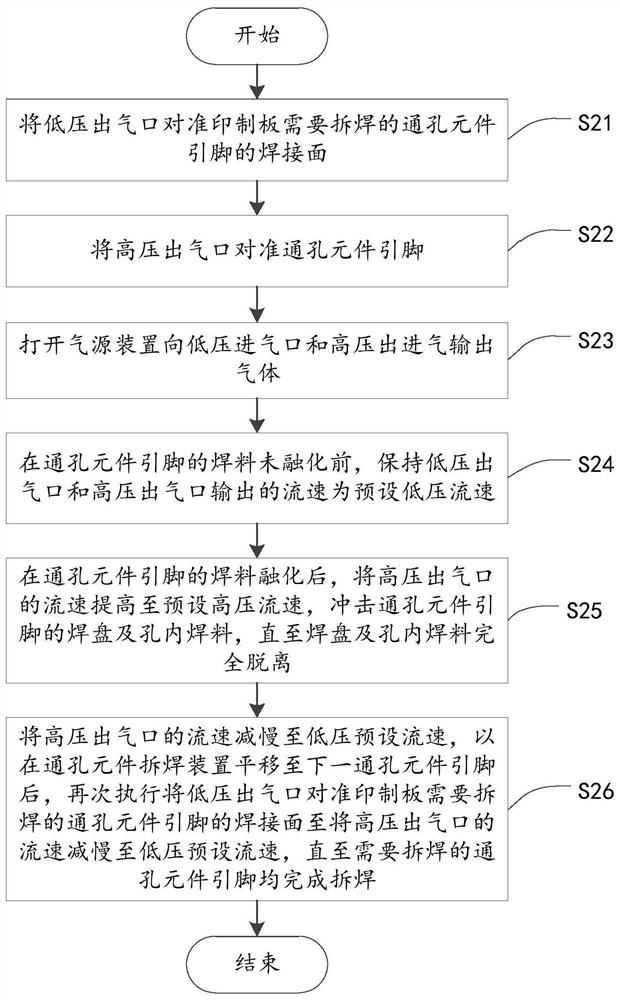

[0032]The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0033] Through the research of the applicant, it is found that for the desoldering of electronic components on the circuit board, a traditional method commonly used is to use a high-temperature electric soldering iron to contact the pins and pads of through-hole devices and heat them one by one, and use a tin suction gun to remove the melted solder from the The solder in the pad and hole is sucked out. When the solder in all pin holes of the device is sucked out, the through-hole device is taken out, and the desoldering is completed.

[0034] In this desoldering method, the tin suction gun uses air negative pressure to absorb the melted solder in the hole. The suction nozzle needs to fit closely with the pad orifice, otherwise it cannot absorb the solder in the hole; because the heating of the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com