Dead-soft tin-coated copper belt for solar cell

A technology for solar cells and tin-coated copper strips, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems affecting welding quality, curling or arching, and cell deformation, so as to improve product competitiveness and reduce stress The effect of releasing and expanding profit margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

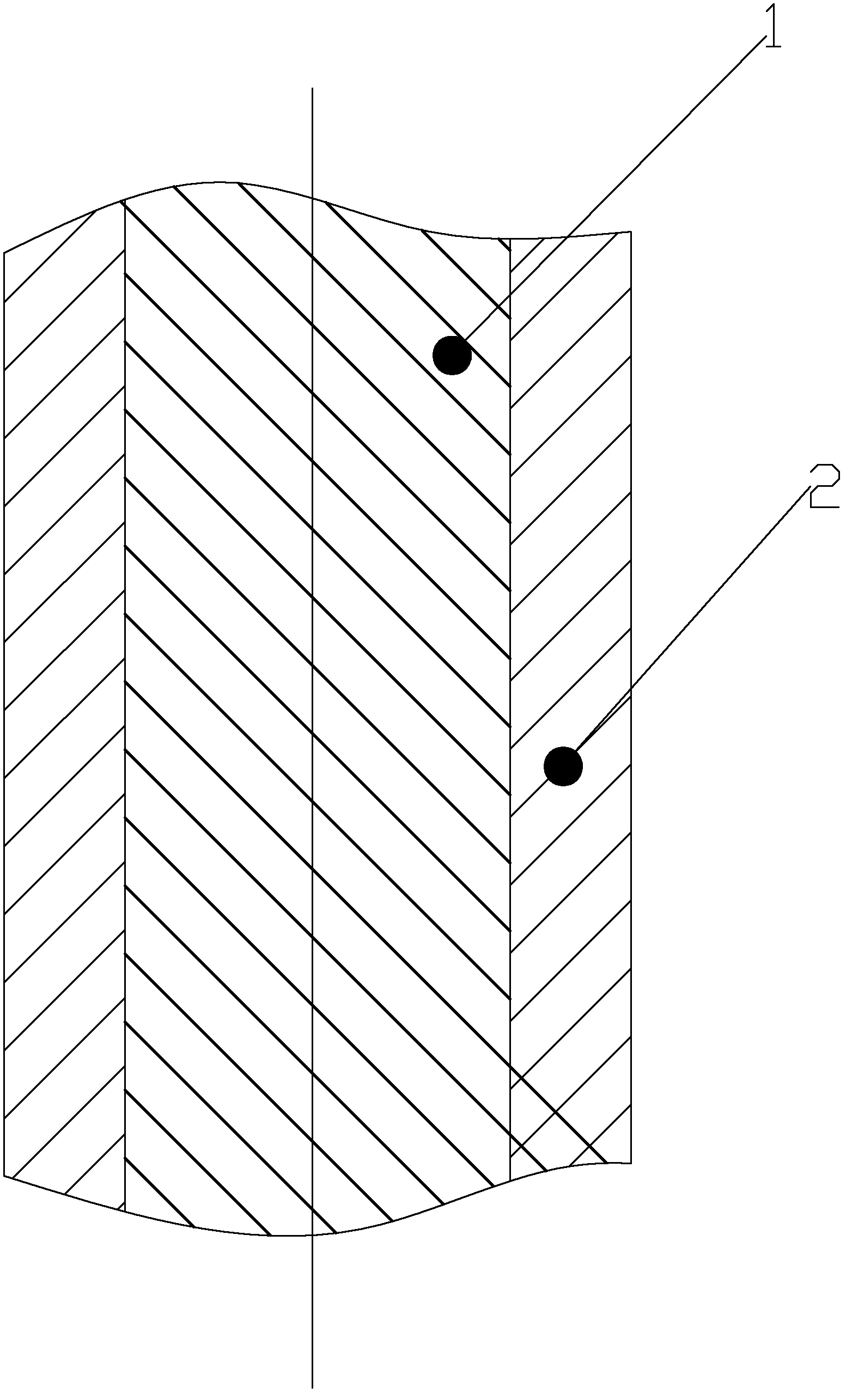

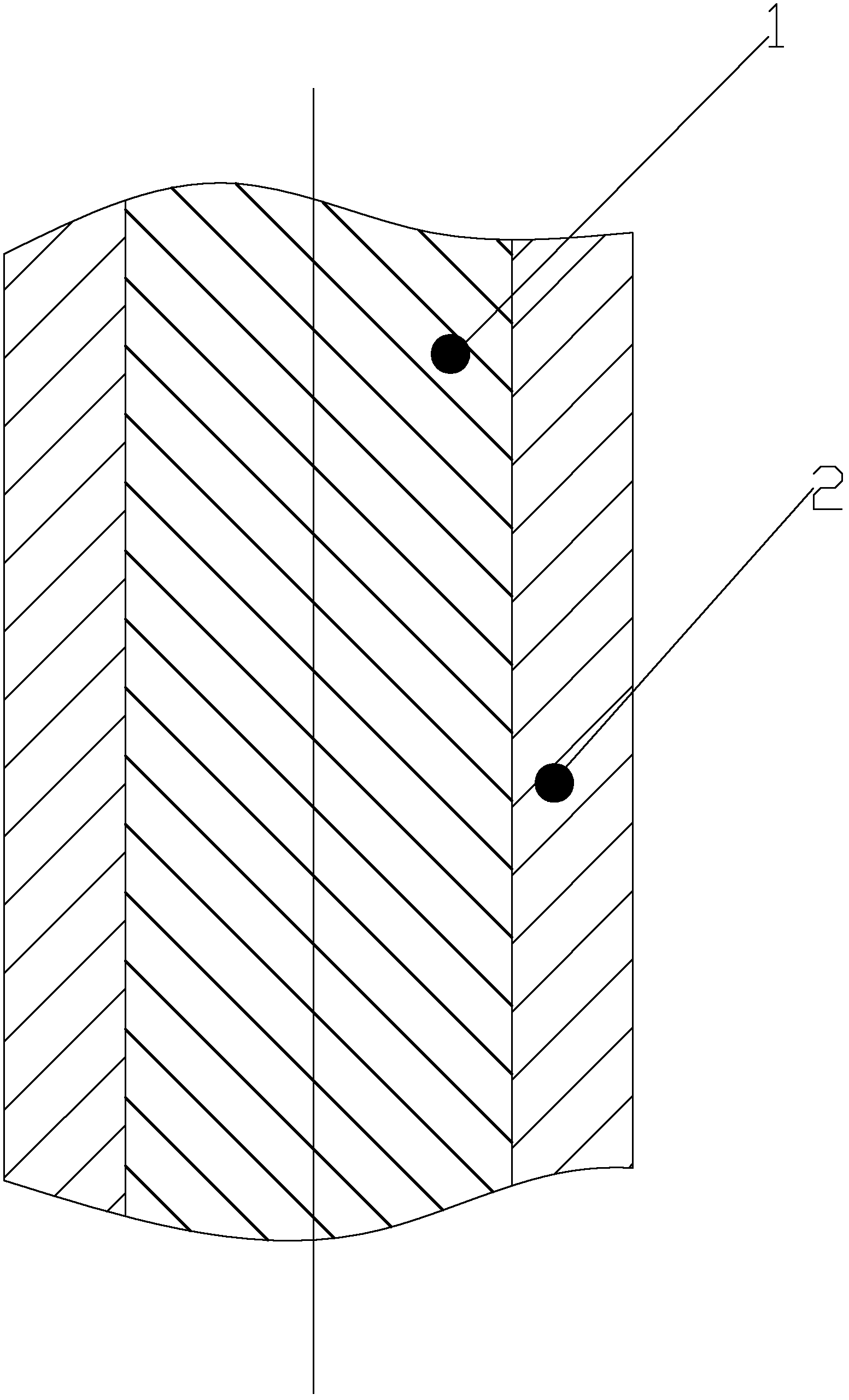

[0011] Such as figure 1 As shown, it includes a copper substrate 1 and an alloy coating 2.

[0012] The invention guarantees the performance of the copper strip before tin coating. The copper is annealed in a gas-protected bright annealing furnace. The gas protection is to ensure that the annealed copper is not oxidized, and at the same time, the numerical control adjustable constant tension unwinding and constant tension winding are added to ensure that the annealed copper meets the performance requirements:

[0013] 1) Copper content ≥ 99.95%

[0014] 2), resistivity TU1≤0.0168Ωmm 2 / m; T2≤0.017241Ωmm 2 / m.

[0015] The invention adopts tin coating in a low-tension process to ensure the finished product requirements of the tin-coated copper strip.

[0016] The alloy coating 2 is evenly coated on the front and back surfaces of the copper substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com