Antioxidant tin-copper alloy brazing filler metal

A technology of alloy solder and tin oxide, which is applied in metal processing equipment, welding/cutting media/materials, welding media, etc., can solve the problem that liquid flux is not easy to store, and achieve improved anti-oxidation protection, good mechanical properties, Effect of improving tensile strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

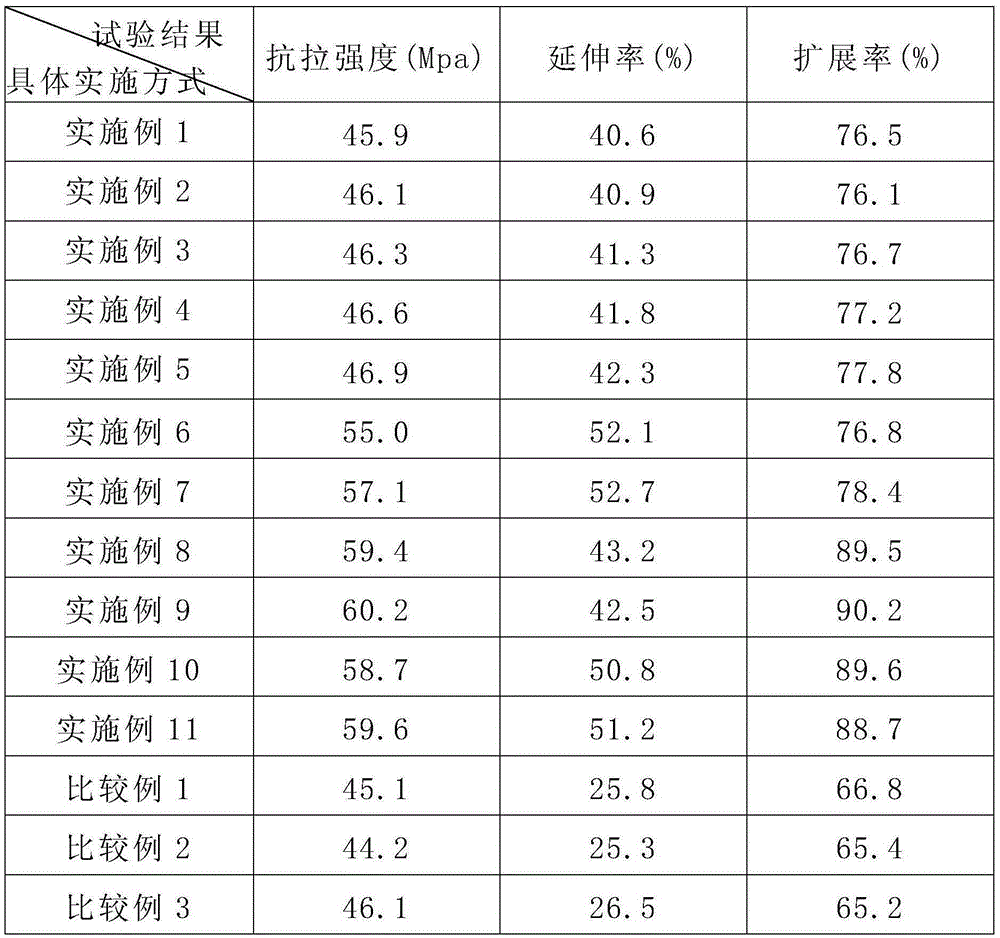

Examples

Embodiment 1

[0019] In the present embodiment, the anti-oxidation tin-copper alloy solder comprises the mass percent of the following components:

[0020] Ag: 0.1%; Cu: 1.0%; anti-oxidation flux material: 3.0%; the rest is Sn and unavoidable impurity elements;

[0021] Taking the anti-oxidation flux material as a whole, the anti-oxidation flux material is mainly made of the following raw materials in mass percentage:

[0022] Rare earth additive: 70%; organic acid: 2.0%; ammonium chloride 3.0%; ammonium fluoride 1.0%; ethyl acetate: 4.0%; Diacid, co-solvent is deionized water.

[0023] In the present embodiment, the anti-oxidation tin-copper alloy solder can be prepared by the following method:

[0024] Weigh the raw materials according to the above mass percentage, add Sn into the furnace, and control the temperature at 300°C to completely melt; then, when the temperature is raised to 320°C, add metal Ag into the Sn liquid and stir fully to form an alloy liquid; after the melting is co...

Embodiment 2

[0026] In the present embodiment, the anti-oxidation tin-copper alloy solder comprises the mass percent of the following components:

[0027] Ag: 1.0%; Cu: 0.5%; anti-oxidation flux material: 1.0%; the rest is Sn and unavoidable impurity elements;

[0028] Taking the anti-oxidation flux material as a whole, the anti-oxidation flux material is mainly made of the following raw materials in mass percentage:

[0029] Rare earth additive: 30%; organic acid: 10%; ammonium chloride 10%; ammonium fluoride 5.0%; ethyl acetate: 5.0%; , the co-solvent is deionized water.

[0030] The specific preparation method of the oxidation-resistant tin-copper alloy solder in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

Embodiment 3

[0032] In the present embodiment, the anti-oxidation tin-copper alloy solder comprises the mass percent of the following components:

[0033] Cu: 0.8%; anti-oxidation flux material: 0.5%; the rest is Sn and unavoidable impurity elements;

[0034] Taking the anti-oxidation flux material as a whole, the anti-oxidation flux material is mainly made of the following raw materials in mass percentage:

[0035] Rare earth additive: 50%; organic acid: 8%; ammonium chloride 10%; ammonium fluoride 8.0%; ethyl acetate: 3.0%; Fatty acid, co-solvent is deionized water.

[0036] The specific preparation method of the oxidation-resistant tin-copper alloy solder in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com