A joint deactivation protection method for air-cooled island and unit

A technology of air-cooling units and air-cooling islands, applied in damage protection, lighting and heating equipment, heat exchange equipment, etc., can solve problems such as uneven distribution of vapor-liquid phase, poor solubility of chemicals, and waste of fuel, so as to shorten the qualification time and prevent Oxidation corrosion, the effect of saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

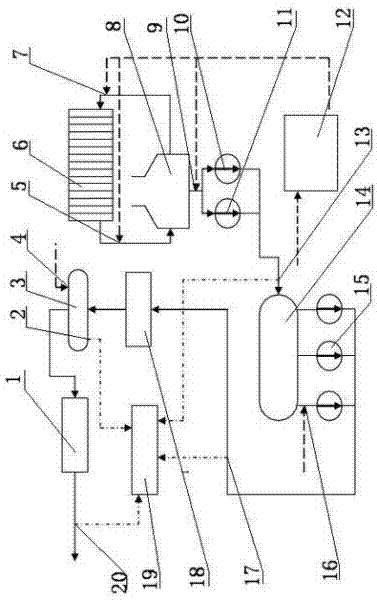

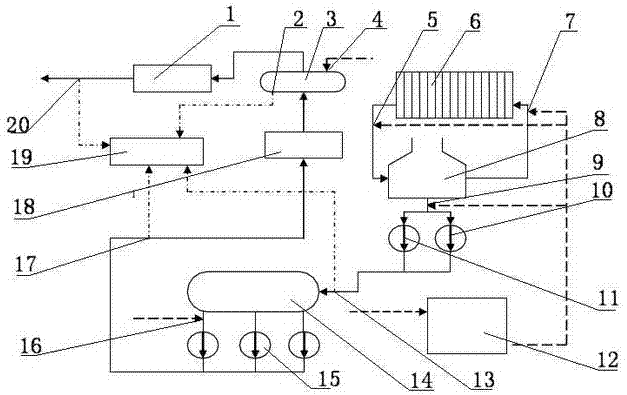

[0018] A combined deactivation protection method for an air-cooled island and a unit. The air-cooled unit includes a superheater 1, a steam drum 3, an economizer 18, a feed water prepump 15, a deaerator 14, a first condensate pump 10, and a second condensate pump. Water pump 11, hydrazine filling device, phosphate filling device and exhaust device 8; also includes special maintenance liquid filling device 12 respectively connected with the input pipe and output pipe of air cooling island 6 and the input pipe of exhaust device 8; The special maintenance fluid filling device 12 includes a maintenance fluid tank and a filling pump; the exhaust device 8 is docked with the air cooling island 6 (see attached figure 1 ); the key improvement is that the joint deactivation protection method includes the following steps:

[0019] 1) Adjust the parameters before the air-cooling unit slides to stop; 1) Dissolve the required concentration of shutdown maintenance fluid in the special mainte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com