Active heat regenerator for room temperature magnetic refrigerator

A room temperature magnetic refrigerator, active technology, applied in the direction of refrigerators, superheaters, refrigeration components, etc., can solve the problems of magnetic refrigerator performance degradation, affecting heat transfer efficiency, and aggravated oxidation, so as to improve the cooling capacity / system heat, enhance the effect of heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

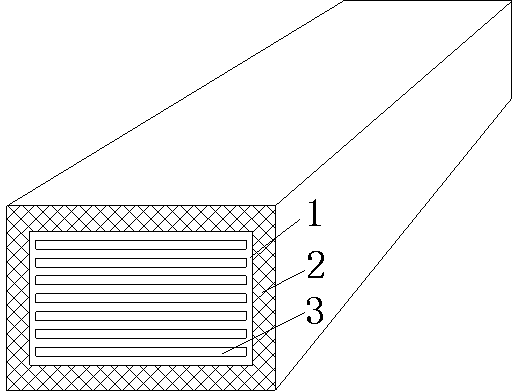

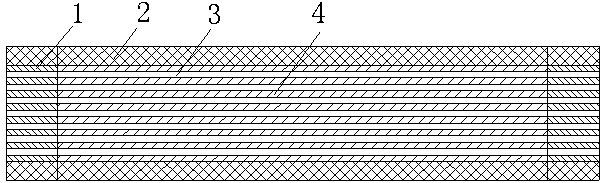

[0027] Such as figure 1 and figure 2 As shown, an active regenerator for a room temperature magnetic refrigerator includes an adiabatic casing 2 and a magnetocaloric working fluid bed arranged in the adiabatic casing 2, and the magnetocaloric working fluid bed is Parallel to each other fine channels 3 for flowing through the heat exchange fluid are evenly arranged in a straight line along the length direction, and the heat exchange fluid is R410a, R134a, R407c or R290.

[0028] Wherein, specifically, the cross-sectional profile of the adiabatic shell 2 and the magnetocaloric working medium bed arranged in the adiabatic shell 2 is rectangular; the cross-sectional profile of the fine channel 3 is rectangular, and the hydraulic diameter is 0.1mm ~3mm, the distance between the fine channels 3 is 0.1mm~3mm.

[0029] At the same time, in order to make the heat exchange fluid evenly flow through the fine channels 3 and improve the heat exchange efficiency, the two ends of the heat...

Embodiment 2

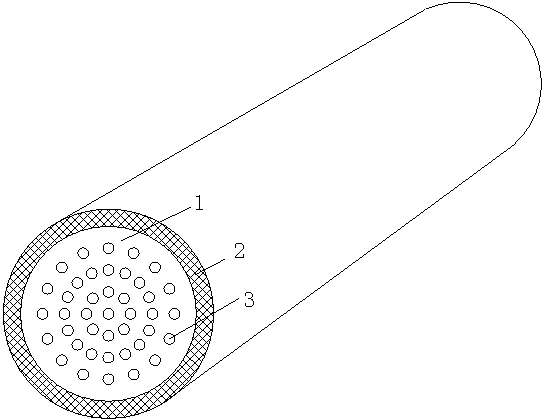

[0032] Such as image 3 with Figure 4 As shown, an active regenerator for a room temperature magnetic refrigerator includes an adiabatic housing 2 and a magnetocaloric working fluid bed arranged in the adiabatic housing 2,

[0033] The magnetocaloric working fluid bed is uniformly arranged in a straight line along the length direction with fine channels 3 parallel to each other for flowing through the heat exchange fluid, and the heat exchange fluid is R410a, R134a, R407c or R290.

[0034] Wherein, specifically, the cross-sectional profile of the adiabatic shell 2 and the magnetocaloric working medium bed arranged in the adiabatic shell 2 is circular; the cross-sectional profile of the fine channel 3 is circular, and the hydraulic diameter is 0.1mm~3mm.

[0035] At the same time, in order to make the heat exchange fluid evenly flow through the fine channels 3 and improve the heat exchange efficiency, the two ends of the heat insulating shell 2 are provided with a deflector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com