Method for intelligently detecting residual amount of solder paste of soldering paste printer

An intelligent detection and solder paste technology, which is applied to the general parts of printing machinery, printing machines, printing, etc., can solve the problems of solder paste residual detection and other problems, and achieve the effect of reducing difficulty, preventing tin shortage and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

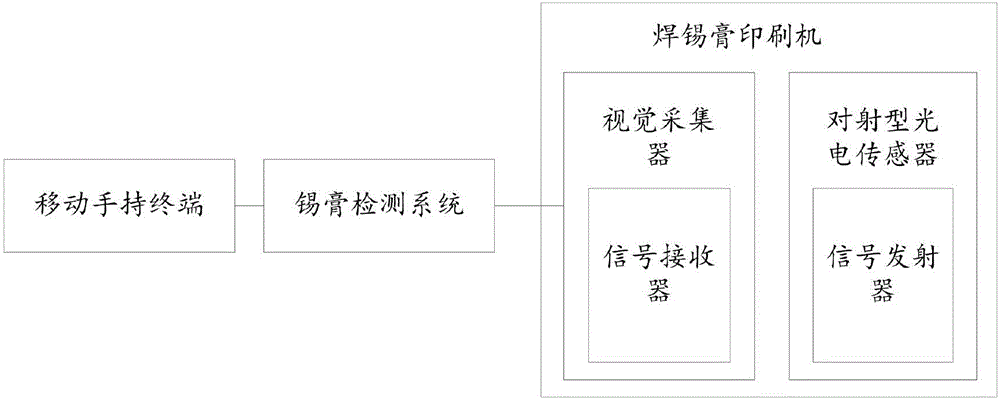

[0014] This embodiment provides a method for intelligently detecting the amount of solder paste in a solder paste printing machine, including: a solder paste detection system, a visual collector, a through-beam photoelectric sensor, and a mobile handheld terminal; the visual collector is provided with a signal receiver, The through-beam photoelectric sensor is provided with a signal transmitter; the visual collector and the through-beam photoelectric sensor are placed in the solder paste printing machine, the solder paste detection system is connected to the visual collector through the USB2.0 interface, and the solder paste The detection system can exchange information with the mobile handheld terminal through the WIFI wireless network.

Embodiment 2

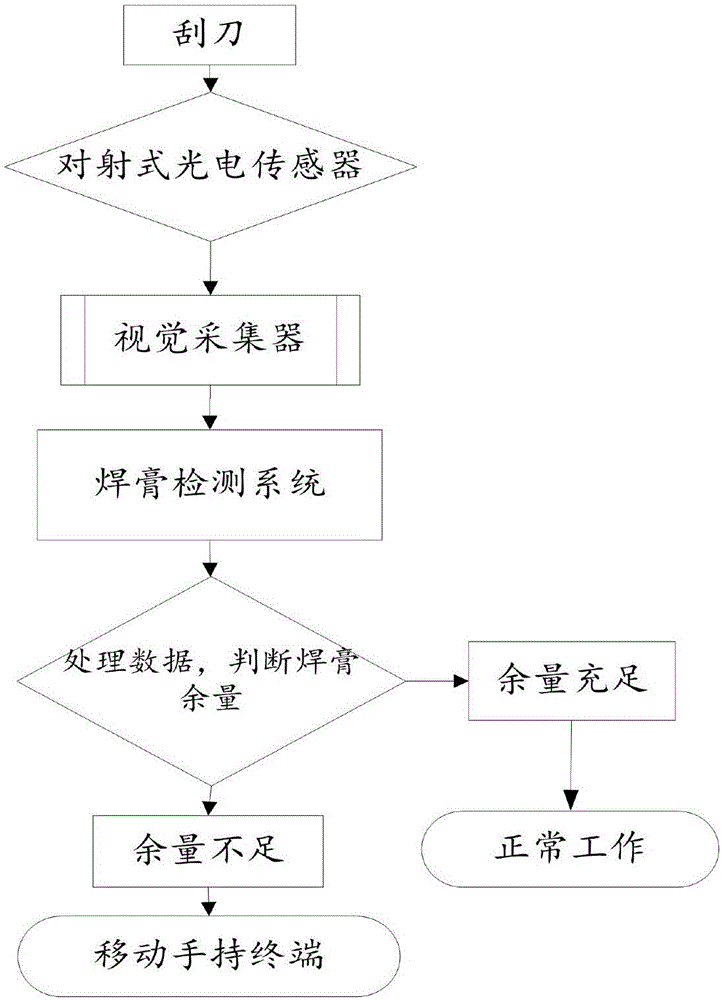

[0016] This embodiment provides a method for intelligently detecting the residual amount of solder paste in a solder paste printing machine based on Embodiment 1, specifically:

[0017] S1: When the scraper in the solder paste printing machine moves to the through-beam photoelectric sensor, its optical path is blocked, and the through-beam photoelectric sensor transmits the signal to the signal receiver in the visual collector through the signal transmitter;

[0018] S2: The visual collector performs image acquisition after receiving the signal, and then sends the acquired image information to the solder paste inspection system;

[0019] S3: The solder paste detection system calculates and processes the image information, and then obtains the remaining amount of solder paste. Once the remaining amount exceeds the maximum and minimum values of the set threshold range, the solder paste detection system will send a corresponding alarm message Send it to the mobile handheld term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com