Automatic desoldering and detinning equipment

An automatic and equipment technology, applied in welding equipment, metal processing equipment, metal processing, etc., can solve the problems of circuit board scrapping, cost loss, environmental pollution, etc., and achieve the effect of thorough tin removal, high safety and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

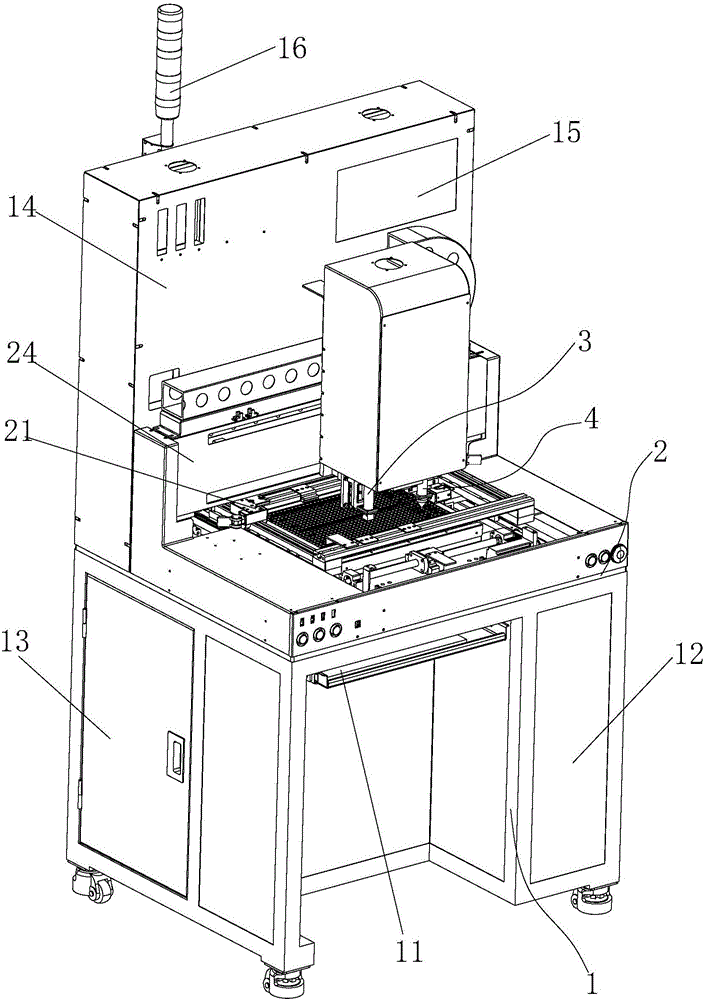

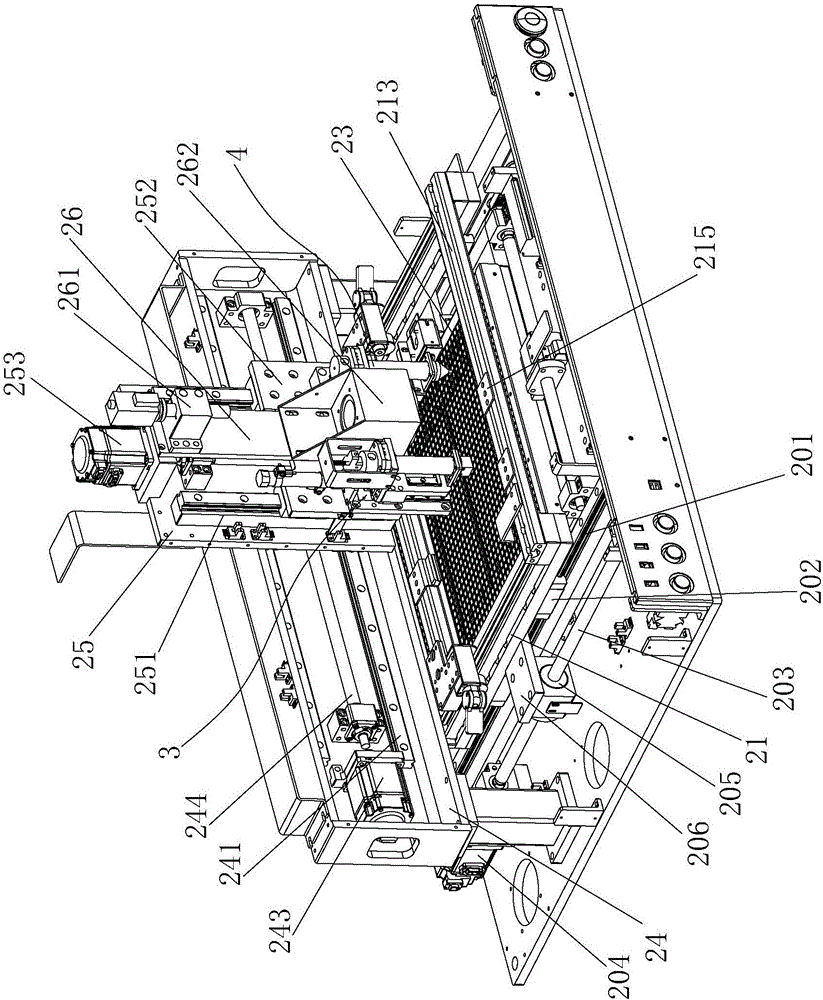

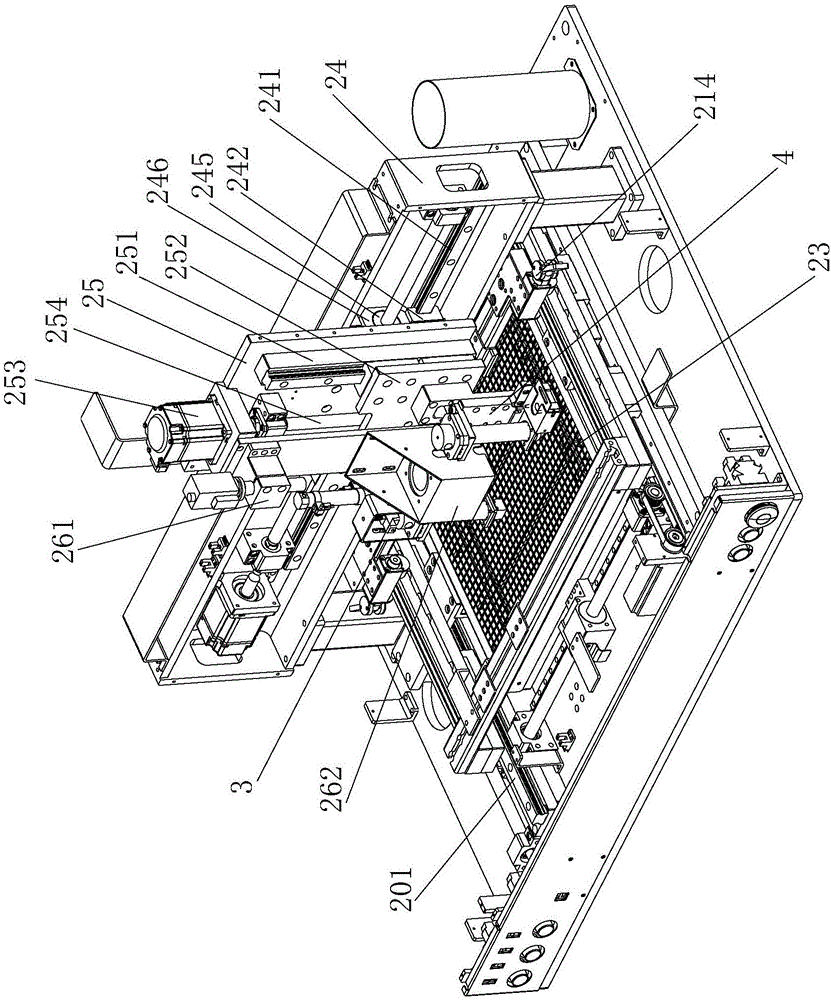

[0034] Such as Figure 1-Figure 4 As shown, what the present invention describes is an automatic desoldering and tin removal equipment. The automatic desoldering and tin removal equipment has a main frame 1, and the main frame 1 is provided with a horizontal workbench 2, wherein:

[0035] A pair of first y-direction rails 201 and corresponding first y-direction sliders 202 are installed on the horizontal workbench 2, and a workpiece is installed between the first y-direction sliders 202 on the two first y-direction rails 201 Fixed jig 21; the first y direction screw mandrel 203 and the first servo motor 204 driving the first y direction screw mandrel 203 are installed on the outside of one of the first y guide rails 201, and the first y direction screw mandrel 203 is provided with There is a matching first screw nut 205 and a first screw nut seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com