PVC furniture board and preparation method thereof

A furniture board and PVC resin technology, applied in the field of PVC furniture board and its preparation, can solve the problems of easy vulcanization pollution, high formula cost, poor environmental protection performance, etc., to improve product stability, save wood consumption, and improve production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

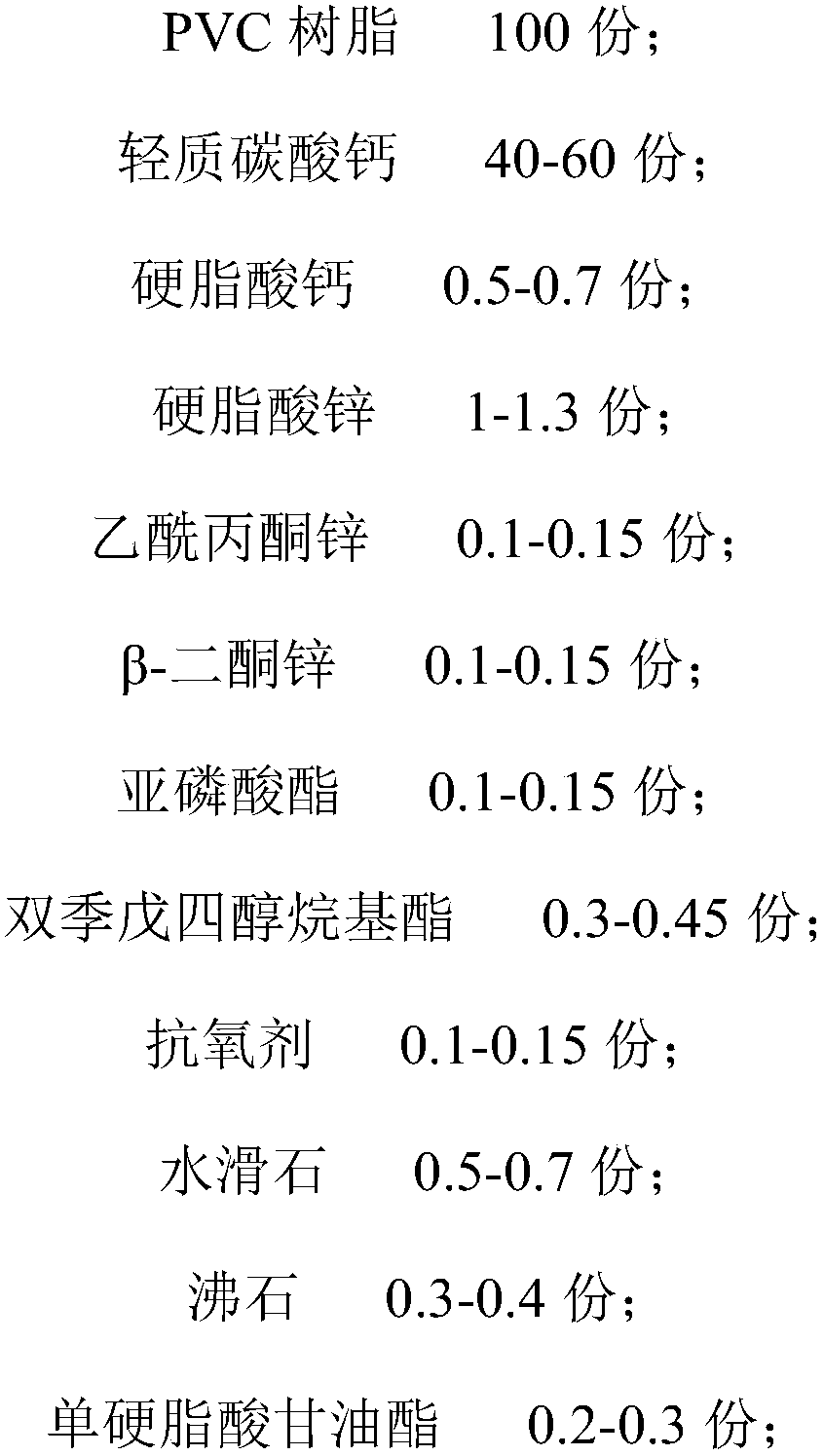

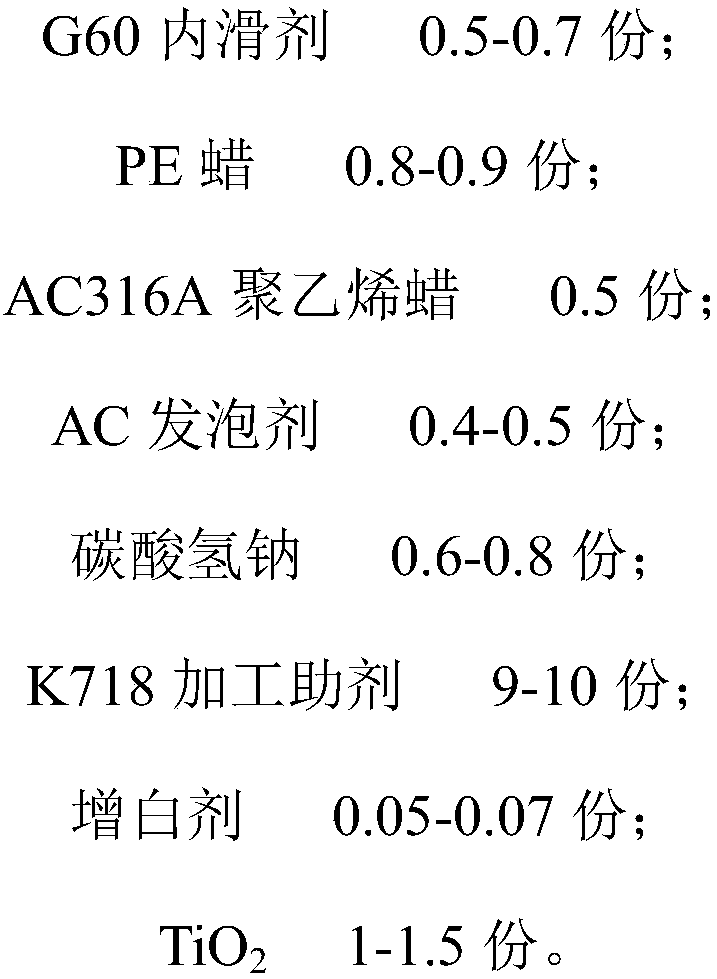

[0047] A kind of PVC furniture board, comprises the raw material as shown in table 1 embodiment 1 weight part.

[0048] The preparation method of the pVC furniture board comprises the following steps:

[0049] S1: Prepare each raw material according to the formula quantity;

[0050] S2: According to the feeding sequence of adding PVC resin and / or self-circulating recycled materials first, then adding K718 processing aid, and finally adding other raw materials, put each raw material into the hot mixing pot, control the stirring speed to 680rpm / min, and set the temperature at 110 ℃ heat mixing for 520s to obtain hot mixture;

[0051] S3: cold mix the hot mix obtained in step S2 at a stirring speed of 320rpm / min for 420 seconds, and reduce the temperature of the hot mix to below 40°C to obtain a cold mix;

[0052] S4: Under vacuum negative pressure, heat the cold mixture obtained in step S3 in the barrel at 155-175°C to become a melt; the melt is extruded through the mold and t...

Embodiment 2

[0063] A kind of PVC furniture board, comprises the raw material of weight part as shown in Table 1 embodiment 2.

[0064] The preparation method of the pVC furniture board comprises the following steps:

[0065] S1: Prepare each raw material according to the formula quantity;

[0066] S2: According to the feeding order of adding PVC resin and / or self-circulating recycled materials first, then adding K718 processing aid, and finally adding other raw materials, put each raw material into the hot mixing pot, control the stirring speed to 680rpm / min, and set the temperature at 115 ℃ heat mixing for 400s to obtain hot mixture;

[0067] S3: cold mix the hot mix obtained in step S2 for 330 seconds at a stirring speed of 320 rpm / min, and lower the temperature of the hot mix to below 40° C. to obtain a cold mix;

[0068] S4: Under vacuum negative pressure, heat the cold mixture obtained in step S3 in the barrel at 155-175°C to become a melt; the melt is extruded through the mold and...

Embodiment 3

[0071] A kind of PVC furniture board, comprises the raw material of weight part as shown in the embodiment 3 of table 1.

[0072] The preparation method of the pVC furniture board comprises the following steps:

[0073] S1: Prepare each raw material according to the formula quantity;

[0074] S2: According to the feeding sequence of adding PVC resin and / or self-circulating recycled materials first, then adding K718 processing aid, and finally adding other raw materials, put each raw material into the hot mixing pot, control the stirring speed to 680rpm / min, and set the temperature at 112 ℃ heat mixing for 480s to obtain hot mixture;

[0075] S3: cold mix the hot mix obtained in step S2 for 370 seconds at a stirring speed of 320rpm / min, and lower the temperature of the hot mix to below 40°C to obtain a cold mix;

[0076] S4: Under vacuum negative pressure, heat the cold mixture obtained in step S3 in the barrel at 155-175°C to become a melt; the melt is extruded through the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com