Novel water-based aluminum formwork concrete release agent and preparation method thereof

A technology of concrete release agent and aluminum formwork, which is applied in the field of concrete and can solve the problems of sticking dust, leaving the bottom of the vertical formwork, and weak wall-hanging ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

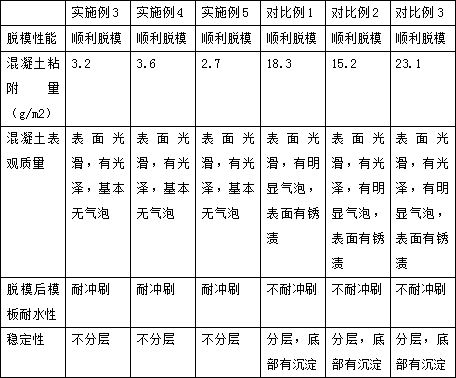

Examples

Embodiment 1

[0035] A novel water-based aluminum formwork concrete release agent is characterized in that it comprises the following components in parts by weight:

[0036] Lubricating oil base oil: 20 parts;

[0037] OP-7: 2 parts;

[0038] Span-80: 1 part;

[0039] Vegetable colloid component: 1.0 part;

[0040] Deionized water: 57.5 parts;

[0041] The plant colloid component is a composition of xanthan gum and guar gum, and its mass ratio is 4:1.

Embodiment 2

[0043] A novel water-based aluminum formwork concrete release agent is characterized in that it comprises the following components in parts by weight:

[0044] Lubricating oil base oil: 35 parts;

[0045] OP-7: 4 copies;

[0046] Span-80: 2 servings;

[0047] Vegetable colloid component: 1.5 parts;

[0048] Deionized water: 76 parts;

[0049] The plant colloid component is a composition of xanthan gum and guar gum, and its mass ratio is 4:1.

Embodiment 3

[0051] A novel water-based aluminum formwork concrete release agent, further, the release agent includes the following parts by weight:

[0052] Lubricating oil base oil: 25 parts;

[0053] OP-7: 2.5 parts;

[0054] Span-80: 1.2 parts;

[0055] Vegetable colloid component: 1.1 parts;

[0056] Deionized water: 59 parts;

[0057] The plant colloid component is a composition of xanthan gum and guar gum, and its mass ratio is 3:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com