Special cleaning agent for food industry and preparation method thereof

A cleaning agent and industrial technology, applied in the field of special cleaning agent for the food industry and its preparation, can solve the problems of difficult cleaning, small usage, and large usage, and achieve the effects of avoiding residual problems, cleaning grease quickly, and long acting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] A special cleaning agent for the food industry and a preparation method thereof. By weight, the components and proportions of the cleaning agent are 4 parts of dodecyl dimethyl betaine, 3.5 parts of sodium hydroxide, 7.8 parts of sodium carbonate, and chlorine 6.7 parts of sodium hydroxide, 1.2 parts of hydrolyzed polymaleic anhydride, and 77.5 parts of water; the preparation method is to combine dodecyl dimethyl betaine, sodium hydroxide, sodium carbonate, sodium chloride, hydrolyzed polymaleic anhydride with Mix with water, dissolve, mix well, stir at 32°C for 12 minutes, and leave the product to get the product.

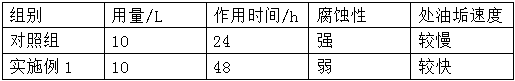

[0011] Table 1

[0012]

[0013] In this example, dodecyl dimethyl betaine has the properties of soft washing, antistatic, dispersing, antibacterial and disinfection; the present invention has the advantages of fast cleaning of grease stains, rich foam and strong wall hanging property, long action time, small usage amount, and water saving , Low corrosiveness, ...

Embodiment 2

[0015] A special cleaning agent for the food industry and a preparation method thereof. By weight, the components and proportions of the cleaning agent are 3.5 parts of dodecyl dimethyl betaine, 3.3 parts of sodium hydroxide, 7.5 parts of sodium carbonate, and chlorine 6.5 parts of sodium hydroxide, 1.0 part of hydrolyzed polymaleic anhydride, 77 parts of water; the preparation method is to combine dodecyl dimethyl betaine, sodium hydroxide, sodium carbonate, sodium chloride, hydrolyzed polymaleic anhydride with Mix with water, dissolve, mix well, stir at 35°C for 15 minutes, and leave the product to get the product.

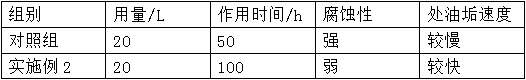

[0016] Table 2

[0017]

[0018] In this embodiment, the combination of sodium chloride and hydrolyzed polymaleic anhydride can achieve the purpose of rapid disinfection and rapid treatment of grease; therefore, the present invention has the advantages of fast cleaning of grease, long action time, small usage, water saving, and low corrosivity. The advantages.

Embodiment 3

[0020] A special cleaning agent for the food industry and a preparation method thereof. By weight, the components and the ratio of the cleaning agent are 4.5 parts of dodecyl dimethyl betaine, 3.8 parts of sodium hydroxide, 8.0 parts of sodium carbonate, and chlorine 7.0 parts of sodium chloride, 1.5 parts of hydrolyzed polymaleic anhydride, 78 parts of water; the preparation method is to combine dodecyldimethyl betaine, sodium hydroxide, sodium carbonate, sodium chloride, hydrolyzed polymaleic anhydride with Mix with water, dissolve, mix well, stir at 30°C for 10 minutes, and leave the product to get the product.

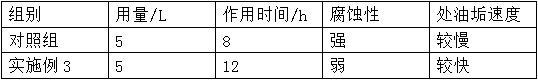

[0021] table 3

[0022]

[0023] The table shows the advantages of fast cleaning of grease stains, long action time, small usage, water saving, and low corrosivity; the invention has the advantages of fast cleaning grease stains, rich foam and strong wall-hanging properties, long action time, small usage, and water saving. It is less corrosive, especially for the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com