Modified thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and thermoplastic elastomer technology, which is applied in the field of modified thermoplastic polyurethane elastomer and its preparation, can solve the problems of poor weather resistance and poor moldability of thermoplastic polyurethane elastomer, and improve product quality, weather resistance, and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

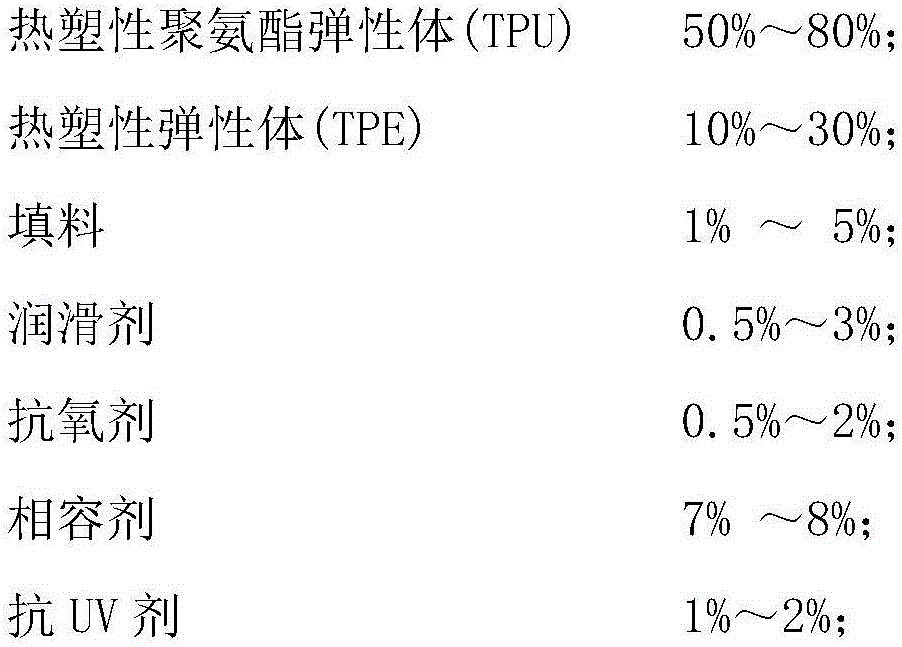

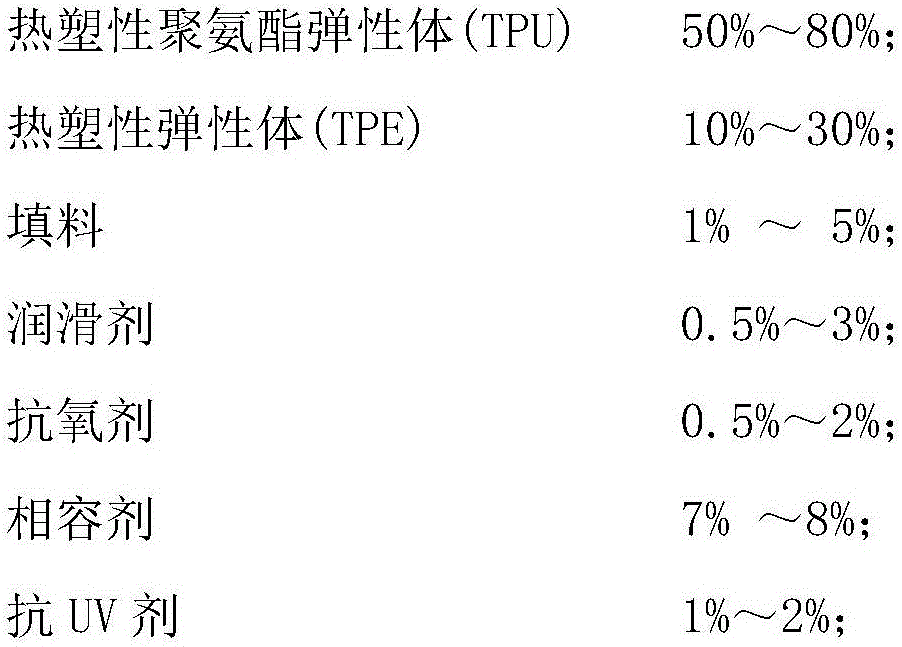

[0029] The modified thermoplastic polyurethane elastomer is composed of the following raw materials in weight percentage: thermoplastic polyurethane elastomer (TPU) 50%; thermoplastic elastomer (TPE) 30%; filler 5%; lubricant 3%; antioxidant 2%; 8% compatibilizer; 2% anti-UV agent. Among them, the thermoplastic elastomer (TPE) adopts a TPE with a hardness of 75A and a melt index of 20 g / 10 min at a melting temperature of 190° C. and a load of 5 kg. The compatibilizer is MAH graft with SEBS as base material, calcium carbonate is used as filler, polyethylene wax is used as lubricant, 1010 is used as antioxidant, and UV326 is used as anti-UV agent.

[0030] Preparation:

[0031] 1), thermoplastic polyurethane elastomer (TPU), thermoplastic elastomer (TPE), filler, lubricant, antioxidant, compatibilizer, anti-UV agent are proportioned according to the above weight percentage;

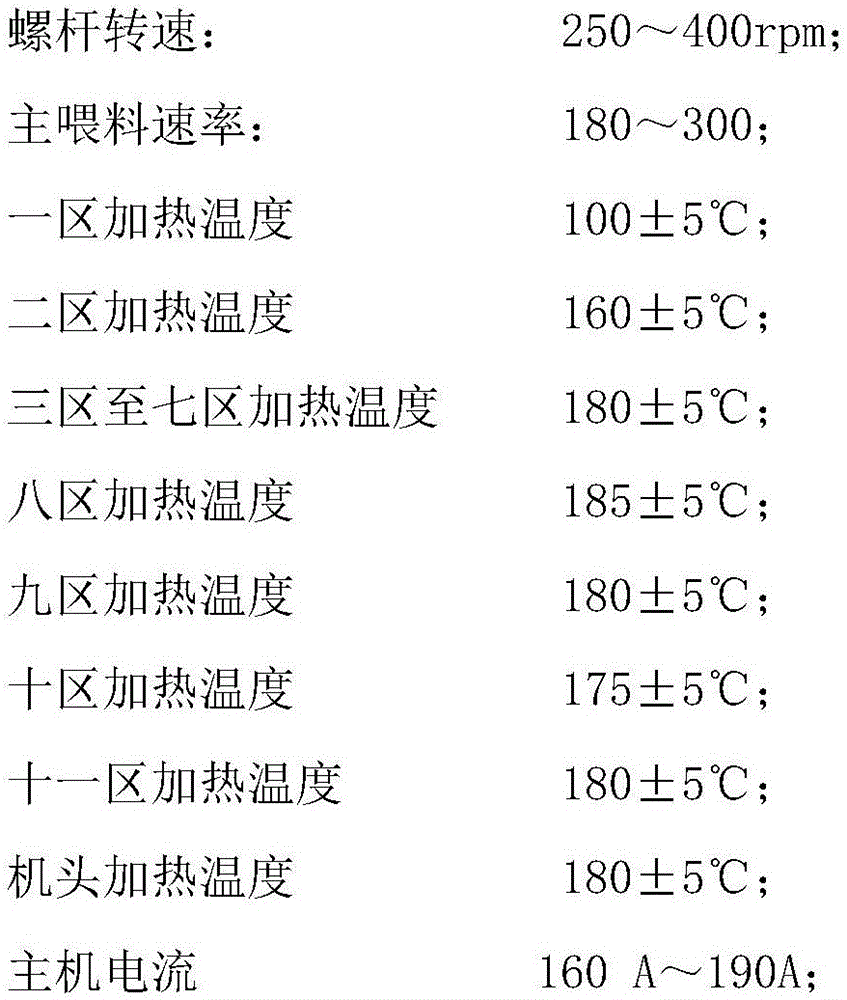

[0032] 2) Add the components weighed in step 1) into a low-speed mixing pot and mix thoroughly to obta...

Embodiment 2

[0037] The modified thermoplastic polyurethane elastomer is composed of the following raw materials in weight percentage: thermoplastic polyurethane elastomer (TPU) 80%; thermoplastic elastomer (TPE) 10%; filler 1%; lubricant 0.5%; antioxidant 0.5%; 7% compatibilizer; 1% anti-UV agent. Wherein, the thermoplastic elastomer (TPE) adopts a TPE with a hardness of 85A and a melting index of 50 g / 10 min at a melting temperature of 190° C. and a load of 5 kg. The compatibilizer adopts MAH graft with PP as the base material. The filler is talcum powder, and the lubricant is a combination of XH204 and XH208. The antioxidant uses 1076. The anti-UV agent adopts UV531.

[0038] Preparation:

[0039] 1) Proportioning thermoplastic polyurethane elastomer (TPU), thermoplastic elastomer (TPE), filler, lubricant, antioxidant, compatibilizer, and anti-UV agent according to the above weight percentage.

[0040] 2) Add the components weighed in step 1) into a low-speed mixing pot and mix tho...

Embodiment 3

[0045] The modified thermoplastic polyurethane elastomer is composed of the following raw materials in weight percentage: thermoplastic polyurethane elastomer (TPU) 65%; thermoplastic elastomer (TPE) 20%; filler 3%; lubricant 1.5%; antioxidant 1.5%; 7.5% compatibilizer; 1.5% anti-UV agent. Wherein, the thermoplastic elastomer (TPE) has a hardness of 80A and a melt index of 30 g / 10 min at a melting temperature of 190° C. under a load of 5 kg. The compatibilizer adopts MAH graft with PE as the base material, the filler adopts glass fiber, the lubricant adopts the combination of EBS, smooth agent 1751, and silicone powder, and the antioxidant adopts 1010 , 1076, and 1098, the anti-UV agent is a combination of UV326 and UV531.

[0046] Preparation:

[0047] 1) Proportioning thermoplastic polyurethane elastomer (TPU), thermoplastic elastomer (TPE), filler, lubricant, antioxidant, compatibilizer, and anti-UV agent according to the above weight percentage.

[0048] 2) Add the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com