Internal demolding agent for epoxy resin LED packaging material, and preparation method thereof

A technology of LED packaging and internal mold release agent, applied in the field of polymer materials, can solve the problems of unmentioned, high reaction temperature, lack of reaction raw materials, etc., to increase safety and controllability, ensure mold release effect, good The effect of the demolding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

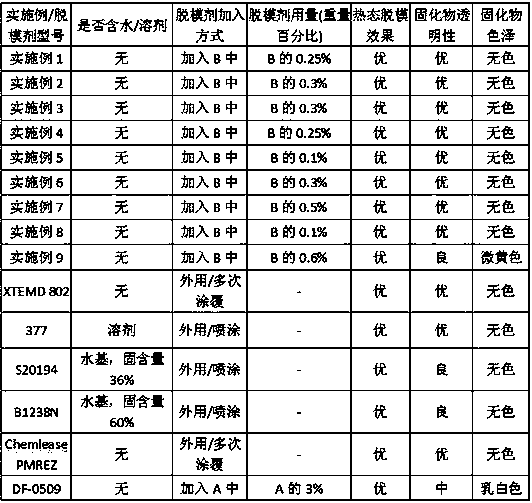

Examples

Embodiment 1

[0032] An internal mold release agent for epoxy resin LED packaging materials, prepared from the following raw materials in parts by weight through addition reaction:

[0033] 120 parts of low hydrogen silicone oil

[0034] Olefin compounds 100 parts

[0035] The amount of platinum catalyst in terms of Pt is 20 ppm of the total amount of low-hydrogen silicone oil and olefin compounds.

Embodiment 2

[0037] An internal mold release agent for epoxy resin LED packaging materials, prepared from the following raw materials in parts by weight through addition reaction:

[0038] 150 parts of low hydrogen silicone oil

[0039] Olefin compounds 200 parts

[0040] The amount of platinum catalyst in terms of Pt is 10 ppm of the total amount of low-hydrogen silicone oil and olefin compounds;

[0041] Among them, the low-hydrogen silicone oil is a linear hydrogen-containing silicone oil, the mass percentage of hydrogen content is 1.2%, and the molecular weight is 1200; the olefin compound is allyl alcohol; the platinum catalyst is a platinum complex of methyl vinyl siloxane .

Embodiment 3

[0043] An internal mold release agent for epoxy resin LED packaging materials, prepared from the following raw materials in parts by weight through addition reaction:

[0044] 100 parts of low hydrogen silicone oil

[0045] 150 parts of olefin compounds

[0046] The amount of platinum catalyst in terms of Pt is 5 ppm of the total amount of low-hydrogen silicone oil and olefin compounds;

[0047] Among them, the low-hydrogen silicone oil is a linear hydrogen-containing silicone oil, the mass percentage of hydrogen content is 1.0%, and the molecular weight is 1400; the olefin compound is styrene; the platinum catalyst is platinum-divinyltetramethyldisiloxane complex Compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com