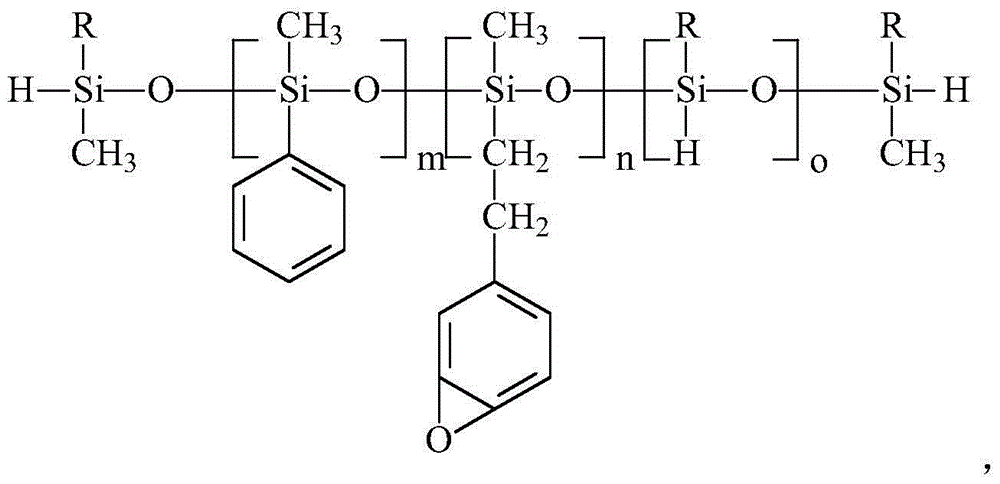

Phenyl hydrogen-containing silicon oil with epoxy side chain and preparation method thereof

A technology of phenyl hydrogen-containing silicone oil and epoxy group, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor mechanical properties and poor adhesion, and achieve convenient operation, good bonding effect, and high transparency. The effect of light rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

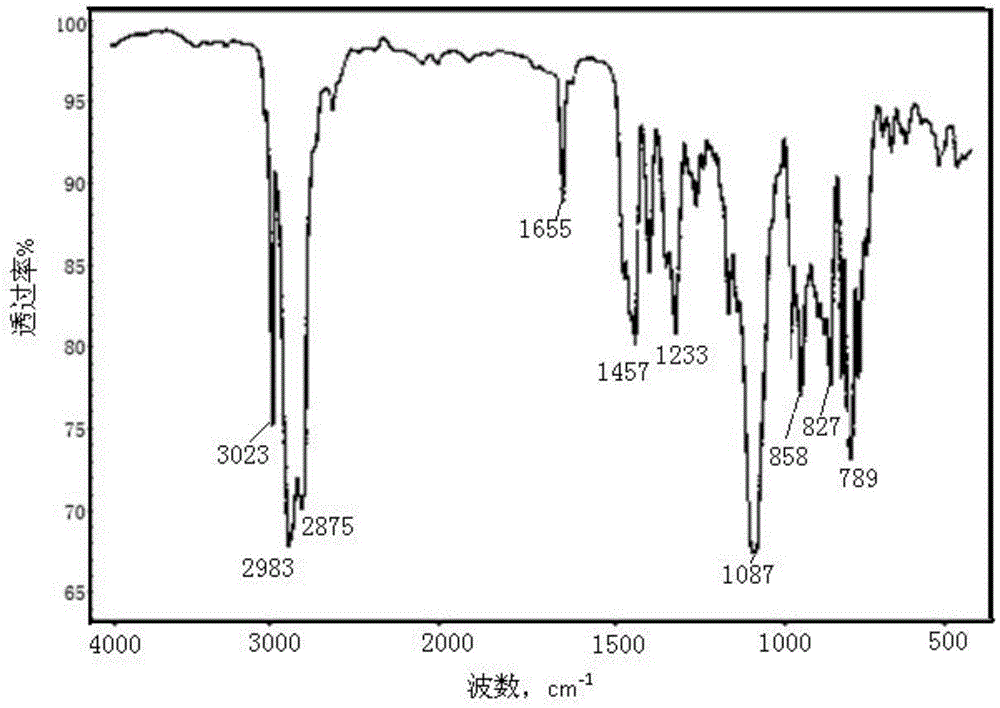

[0031] A preparation method of phenyl hydrogen-containing silicone oil containing epoxy groups in the side chain, specifically comprising the steps of:

[0032] (1) Preparation of Cyclosiloxane Containing Epoxycyclohexane Group

[0033] Under a nitrogen atmosphere, 100 parts by weight of the hydrogen-containing cyclic mixture and 206 parts by weight of 4-vinyl epoxycyclohexane are added in a 1000ml four-necked flask equipped with a stirrer, a condenser tube, a constant pressure funnel and a thermometer, Add 100 parts by weight of toluene, 0.001 parts by weight of chloroplatinic acid-isopropanol solution, and 0.001 parts by weight of 4-methoxyphenol at the same time; then raise the temperature to 80°C and react for 2h. Distill under reduced pressure to remove the solvent and residual low boilers to obtain a liquid with a viscosity of 3000mPa.s, that is, cyclosiloxane containing epoxycyclohexane groups.

[0034] The cyclosiloxane containing epoxy cyclohexane group of above-ment...

Embodiment 2

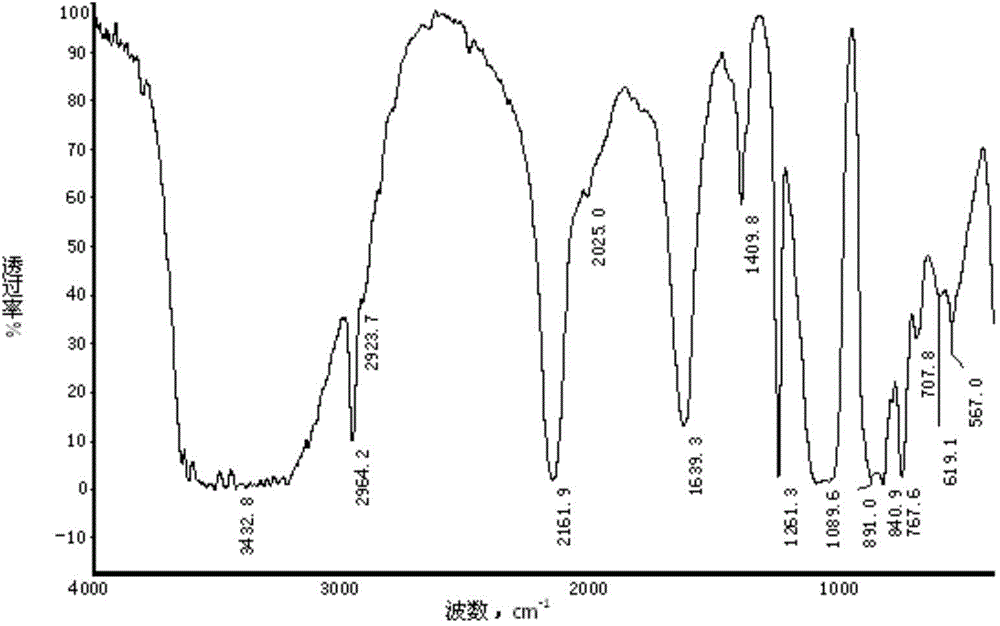

[0050] (1) Preparation of Cyclosiloxane Containing Epoxycyclohexane Group

[0051] Under a nitrogen atmosphere, 100 parts by weight of hydrogen-containing cyclic bodies and 208 parts by weight of 4-vinyl epoxycyclohexane were added to a 1000ml four-necked flask equipped with a stirrer, a condenser tube, a constant pressure funnel and a thermometer, and 100 parts by weight of Part cyclohexane, 0.002 parts by weight of chloroplatinic acid, and 0.002 parts by weight of hydroquinone were added at the same time; then the temperature was raised to 85°C, and the reaction was carried out for 6h. The reaction mixture was distilled under reduced pressure at -0.096MPa at 155°C to remove the solvent and Residual low boilers give a light yellow liquid with a viscosity of 3100mPa.s, namely cyclosiloxane containing epoxycyclohexane groups.

[0052] According to the national standard GB / T 1677-2008, the epoxy value of the plasticizer is determined to be 0.54; it is close to the theoretical va...

Embodiment 3

[0061] (1) Preparation of Cyclosiloxane Containing Epoxycyclohexane Group

[0062] Under a nitrogen atmosphere, add 100 parts by weight of hydrogen-containing cyclic body and 210 parts by weight of 4-vinyl epoxycyclohexane into a 1000ml four-necked flask equipped with a stirrer, a condenser tube, a constant pressure funnel and a thermometer, and add 100 parts by weight of Part cyclohexane, 0.003 parts by weight of chloroplatinic acid, and 0.003 parts by weight of hydroquinone were added at the same time; then the temperature was raised to 90°C, and the reaction was carried out for 10h. The reaction mixture was distilled under reduced pressure at -0.096MPa at 160°C to remove the solvent and Remaining low boilers, a light yellow liquid with a viscosity of 4300mPa.s is obtained, which is the cyclosiloxane containing epoxycyclohexane group.

[0063] According to the national standard GB / T 1677-2008, the epoxy value of the plasticizer is determined to be 0.54; it is close to the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com