Preserved fruit circular spraying vacuum sugar-soaking equipment

A technology of circulating spraying and vacuum soaking sugar, which is applied in confectionery, confectionery industry, food science and other directions, can solve the problems of unfavorable tank maintenance, increase platform, trouble in taking materials, etc., to shorten the time of sugar soaking, The effect of avoiding pollution and fast feeding and reclaiming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

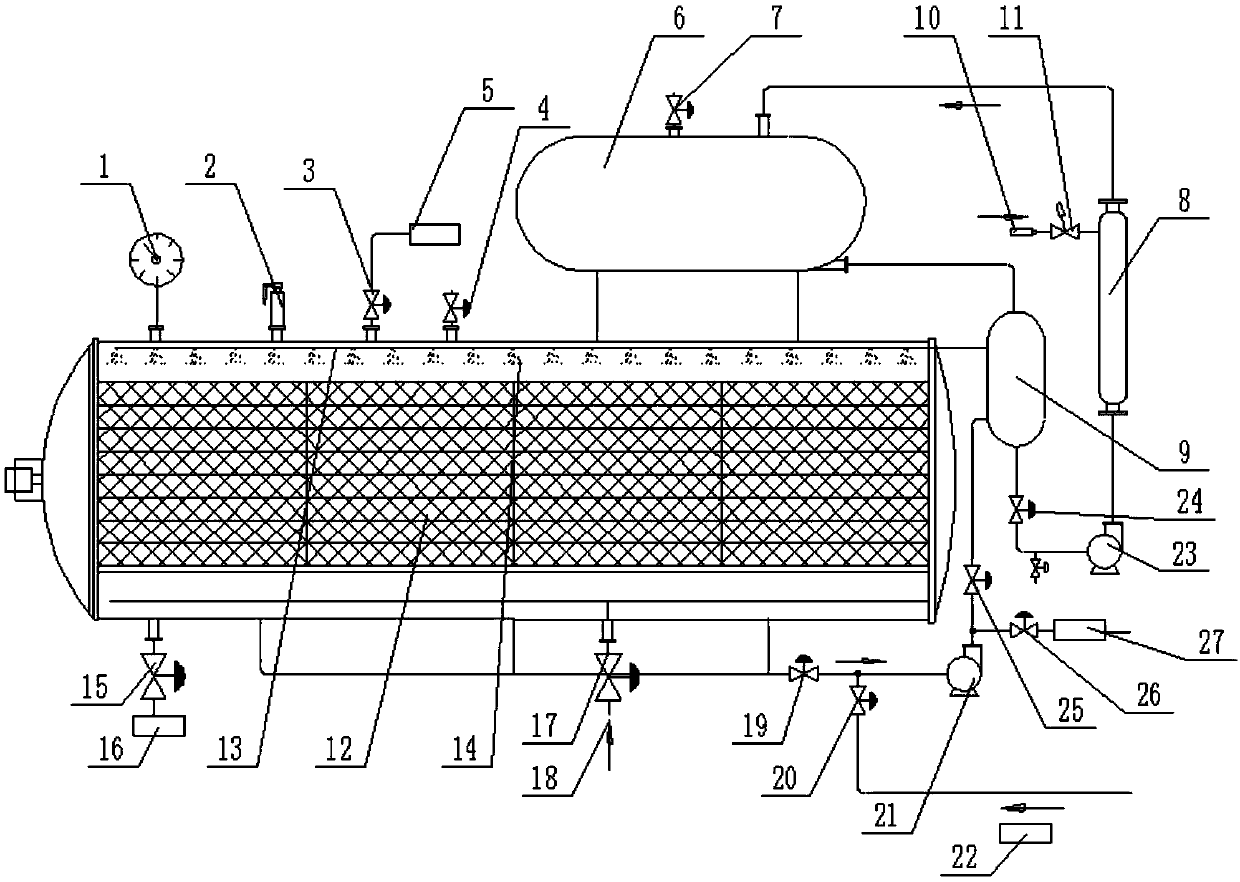

[0030] When working, the sugar liquid enters from the feed port 22, enters the sugar liquid circulating pump 21 through the valve A20, exits from the sugar liquid circulating pump 21 and enters the heat exchanger 9 through the valve B25, and enters the spray pipe after coming out of the heat exchanger 9 13. Spray from the spray head 14 to soak the preserved fruit in the sugar soaking tank 12 evenly, and the vacuum pump 5 extracts the air in the sugar soaking tank 12 to ensure that the inside of the sugar soaking tank 12 is vacuum, and the steam inlet B 18 is simultaneously introduced into the Steam keeps the temperature inside the sugar soaking tank 12, thereby improving the sugar soaking efficiency. The excess sugar solution in the sugar soaking tank 12 enters the sugar solution circulating pump 21 through the valve 19 from the pipeline at the bottom of the sugar soaking tank 12, and the sugar soaking is completed. The excess sugar liquid can be discharged from the discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com