Deep eutectic solvent type hot galvanizing additive and preparation method and application thereof

A deep eutectic solvent, hot-dip galvanizing technology, applied in hot-dip plating process, coating, metal material coating process, etc. Different, ignoring economic, environmental protection and other issues, to achieve the effect of shortening drying time, promoting sustainable development and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-28

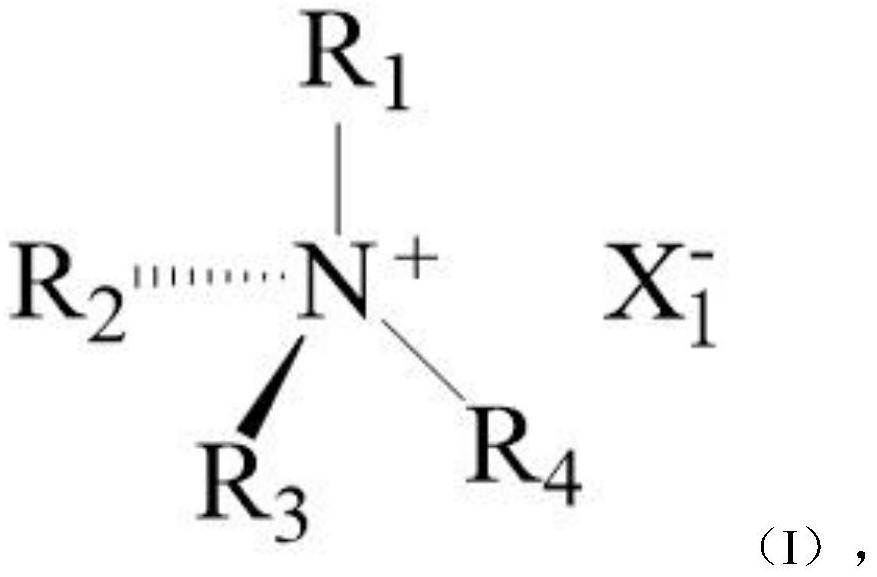

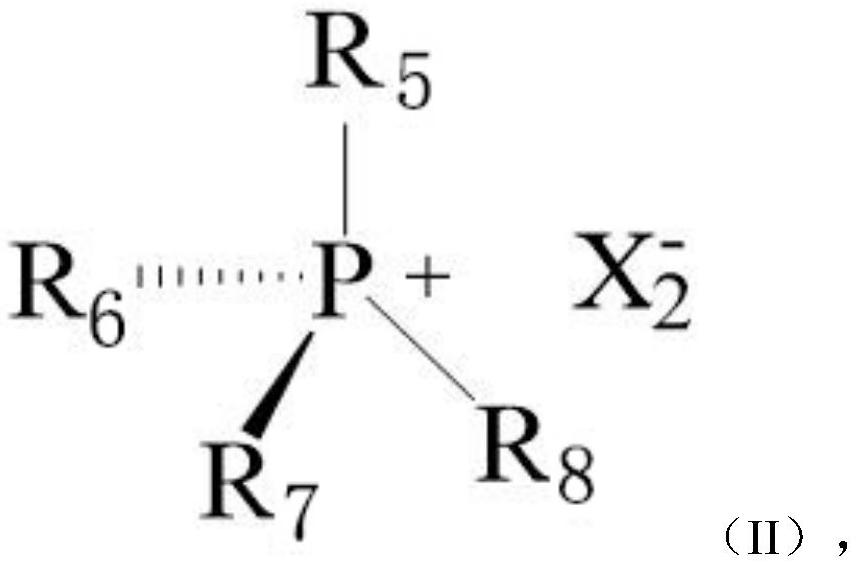

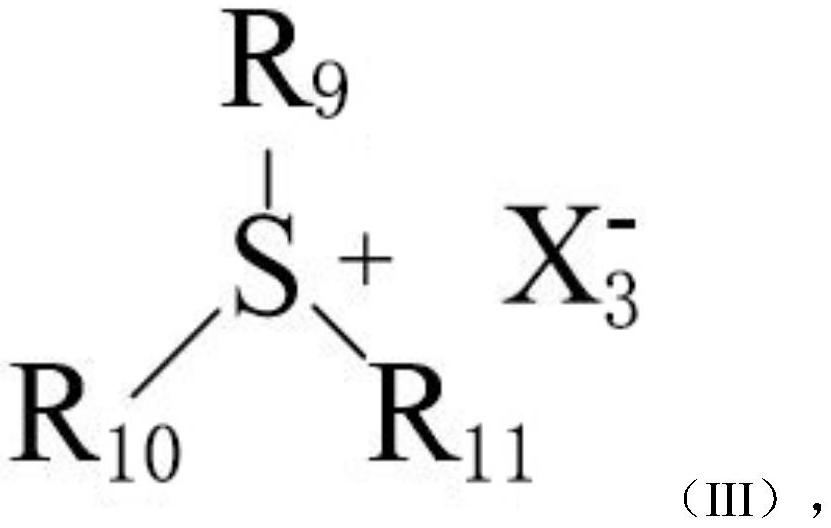

[0056] Embodiment 1-28 Preparation method of deep eutectic solvent-based hot-dip galvanizing additive

[0057] Examples 1-28 are respectively a preparation method of deep eutectic solvent-based hot-dip galvanizing additives. They are deep eutectic solvents, non- Heat the ionic surfactant, inorganic salt and deionized water to 40-70°C, mix well, and let it stand for 9-12 hours to obtain the corresponding deep eutectic solvent hot-dip galvanizing additives, which are marked as J1-J28 in sequence;

[0058] Among them, the deep eutectic solvent is prepared by mixing hydrogen bond donors and hydrogen bond acceptors with a molar ratio of 1-2:1 (see Table 1-2 for the structure and label code); the structure and label of nonionic surfactants The code is shown in Table 3;

[0059] The preparation methods of Examples 1-28 are basically the same, the difference lies in the selection of raw materials and the adjustment of other process parameters, see Table 4-7 for details.

[0060] Tab...

Embodiment 29

[0077] Example 29 Application of deep eutectic solvent-based hot-dip galvanizing additives

[0078] 1) Preparation of comparative hot-dip galvanizing additives

[0079] Prepare corresponding comparative hot-dip galvanizing additives CJ1-CJ5 according to the following methods:

[0080] ①Comparative hot-dip galvanizing additive CJ1:

[0081] Prepare plating flux additive according to the method in patent document CN101126142A: get tetradecyl dimethyl benzyl ammonium chloride 6.3kg, isopropanol 1.2kg, alkylphenol polyoxyethylene (12) ether 0.9kg, fluorine zirconium Potassium acid potassium 0.1kg and deionized water 3kg were placed in a reaction vessel with a heating device, kept stirring at 50°C for 2 hours, lowered to room temperature and adjusted to 10 liters with deionized water, and stirred evenly to obtain a comparative heat Galvanizing additive CJ1.

[0082] ②Comparative hot-dip galvanizing additive CJ2:

[0083] According to the choline chloride: ethylene glycol molar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com