Two-step SuperDyma alloy hot dipping technology for structural steel

A technology for structural steel and alloy, which is applied in the field of two-step hot-dip SuperDyma alloy plating on structural steel, to achieve the effects of good coating quality, lower production costs, and easy control of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

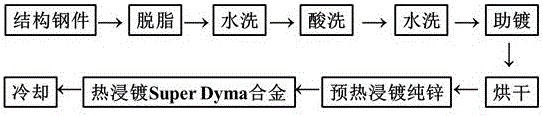

Method used

Image

Examples

Embodiment 1

[0022] First, two crucibles filled with pure zinc and SuperDyma alloy with Zn-11 wt.%Al-3 wt.% Mg-0.2 wt.%Si were placed in a pit furnace and heated to 450°C and kept at a constant temperature.

[0023] Surface cleaning of Q195 structural steel → degreasing with 15% NaOH solution at 70-90°C → washing with water → pickling with 10-15% hydrochloric acid solution → washing with water → 200g / L NH with a weight ratio of 1.2:1 at 70-90°C 4 Cl-ZnCl 2 Help plating in aqueous solution→drying after treatment, immerse in 450℃ pure zinc bath for pre-plating for 10s, take it out and place it in 450℃ SuperDyma alloy bath for 10s, 20s, 30s, 60s, 90s and 120s, and finally Remove from water to cool.

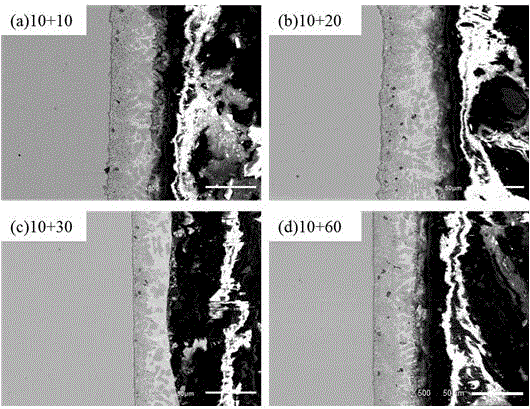

[0024] The surface quality of the obtained plated parts is very good. figure 2 shown. The cross-sectional structure of the obtained coating is as follows image 3 shown. According to the analysis of scanning electron microscope and energy dispersive analyzer, it is found that the Fe with a ...

Embodiment 2

[0026] It is basically the same as Example 1, except that: after pretreatment, the Q195 steel is pre-coated in a pure zinc bath at 450°C for 5 seconds, and then dip-coated in a SuperDyma alloy bath at 450°C for 10 seconds and 20 seconds respectively. 30s and 60s and then take out the water to cool.

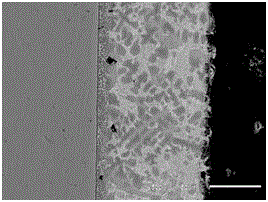

[0027] The microstructure of the coating obtained after pre-plating for 5 s and dipping for 10 is as follows Figure 4 shown. Its Fe 2 Al 5 Zn x The thickness of the mixed layer with the liquid phase becomes thinner, and the coating is mainly formed by the solidified structure of the SuperDyma alloy liquid in the outer layer. That is to say, by shortening the time of pre-plating pure zinc, the Fe 2 Al 5 Zn x The thickness of the mixed layer with the liquid phase, and then the total thickness of the coating is controlled by controlling the amount of alloy liquid.

Embodiment 3

[0029] It is basically the same as Example 1, except that: after pretreatment, the Q195 steel is pre-coated in a pure zinc bath at 430°C for 10 s, and then dip-coated in a SuperDyma alloy bath at 450°C for 10 s and 20 s respectively. , 30s and 60s and then take out the water to cool.

[0030] The microstructure of the coating obtained after pre-plating for 10 s and dipping for 10 s is as follows Figure 5 shown. Its coating structure is basically the same as that in Example 1, except that Fe 2 Al 5 Zn xThe thickness of the mixed layer with the liquid phase is thinner than that after immersion plating at 450°C for the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com