Hot dip galvanizing processing technology

A processing technology, hot-dip galvanizing technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems of easy color difference on the surface of the workpiece, difficult to meet the zinc layer thickness, and high qualification rate of the workpiece. Achieve the effect of good galvanizing effect, reducing the thickness of zinc layer and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

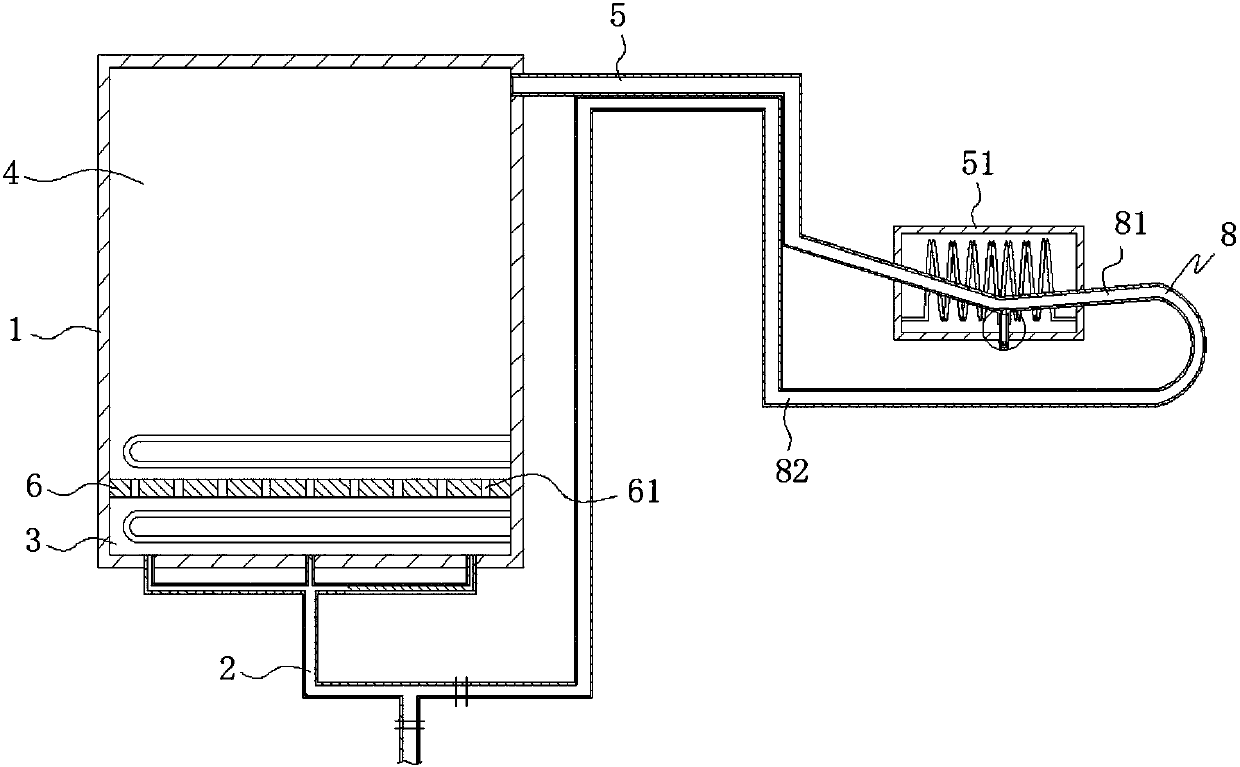

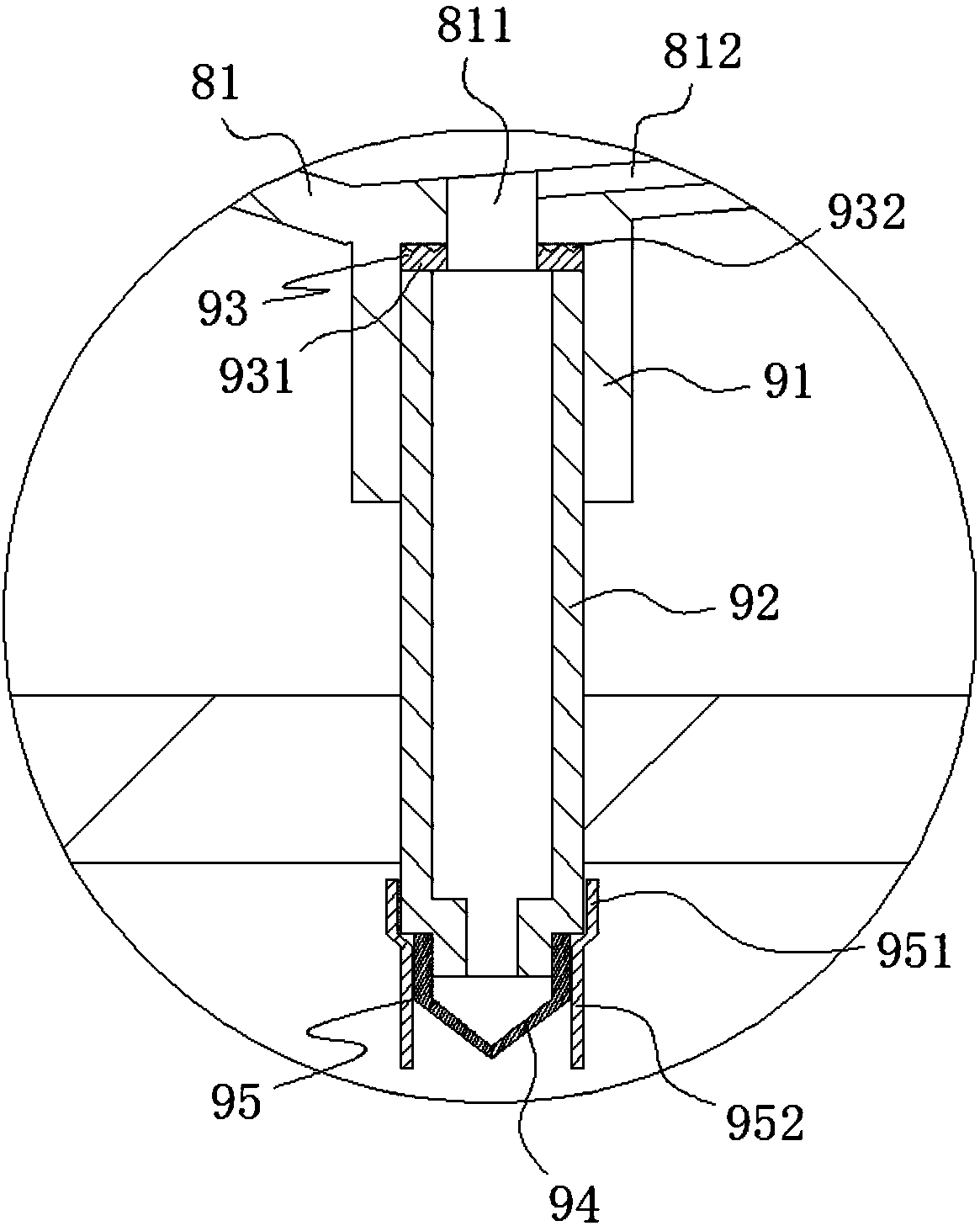

[0030] Such as figure 1As shown, a hot-dip galvanizing process includes the following steps: (1) Degreasing: place the workpiece to be processed in a degreasing solution for 20 minutes, and the temperature of the degreasing solution is 80°C during degreasing; specifically, the degreasing solution It is prepared by mixing degreasing agent and water at a ratio of 1:20; the degreasing agent is composed of components in proportion by weight: 10 parts of sodium carbonate, 2.5 parts of surfactant, 4 parts of trisodium phosphate; (2) acid Washing: Wash the workpiece with hydrochloric acid solution for 35 minutes, and then rinse the workpiece with clean water. The concentration of the above hydrochloric acid solution is 10mol / L; (3) Waste liquid neutralization: the water used to wash the workpiece in step (2) flows to the neutralization tank After the neutralization reaction, it is discharged to the outside. Specifically, the solution in the neutralization pool is sodium hydroxide sol...

Embodiment 2

[0037] A hot-dip galvanizing process, comprising the following steps: (1) Degreasing: place the workpiece to be processed in a degreasing solution for 30 minutes, and the temperature of the degreasing solution is 85°C during degreasing; specifically, the degreasing solution is made of a degreasing agent It is prepared by mixing with water at a ratio of 1:20; the degreasing agent is composed of components in proportion by weight: 20 parts of sodium carbonate, 4.5 parts of surfactant, and 6 parts of trisodium phosphate; (2) pickling: use Wash the workpiece with hydrochloric acid solution for 40 minutes, and then rinse the workpiece with clean water. The concentration of the above hydrochloric acid solution is 10mol / L; (3) Waste liquid neutralization: the water used to wash the workpiece in step (2) flows to the neutralization tank for neutralization After the reaction, it is discharged to the outside. Specifically, the solution in the neutralization pool is a sodium hydroxide sol...

Embodiment 3

[0041] A hot-dip galvanizing process, comprising the following steps: (1) Degreasing: place the workpiece to be processed in a degreasing solution for 25 minutes, and the temperature of the degreasing solution is 85°C during degreasing; specifically, the degreasing solution is made of a degreasing agent It is prepared by mixing with water at a ratio of 1:20; the degreasing agent is composed of components in parts by weight: 20 parts of sodium carbonate, 3 parts of surfactant, and 5 parts of trisodium phosphate; (2) pickling: use Wash the workpiece with hydrochloric acid solution for 40 minutes, and then rinse the workpiece with clean water. The concentration of the above hydrochloric acid solution is 10mol / L; (3) Waste liquid neutralization: the water used to wash the workpiece in step (2) flows to the neutralization tank for neutralization After the reaction, it is discharged to the outside. Specifically, the solution in the neutralization pool is a sodium hydroxide solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com