Textile dip dyeing equipment

An equipment and textile technology, applied in the field of textile impregnation and dyeing equipment, can solve the problems of affecting processing quality, producing mucus, difficult to color, etc., to achieve the effect of improving processing quality, prolonging service life and reducing centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

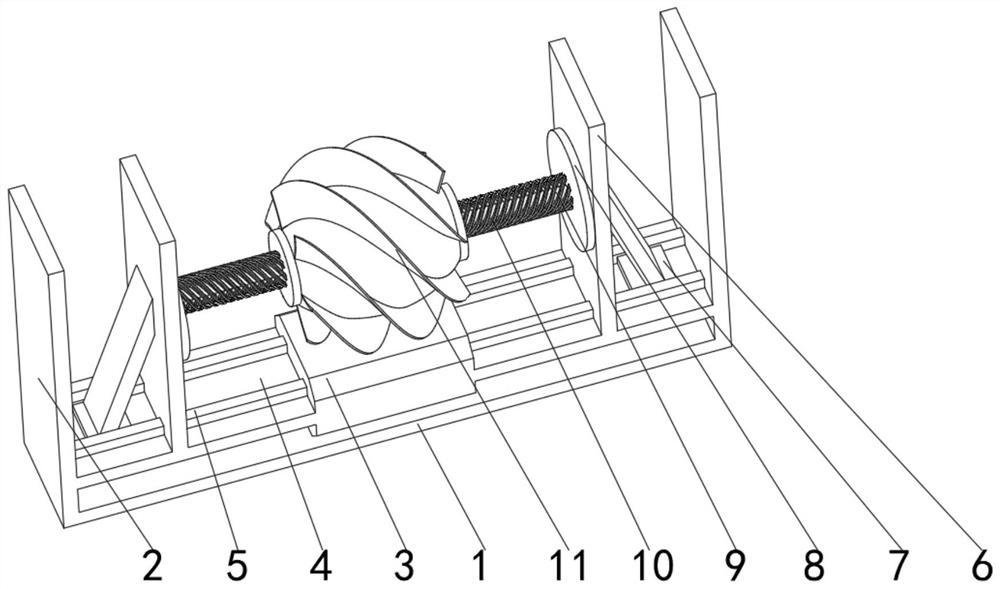

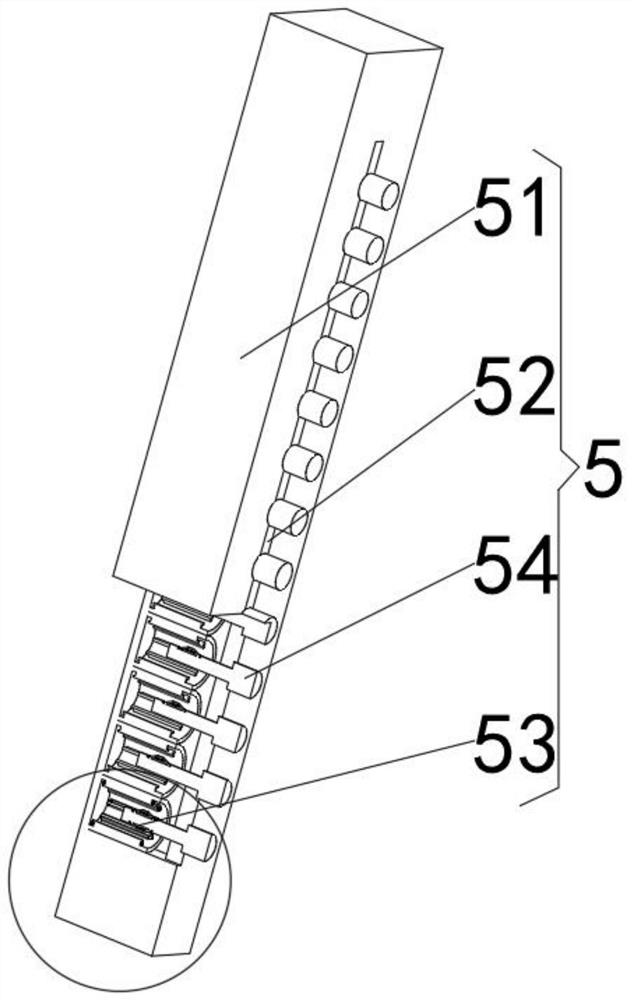

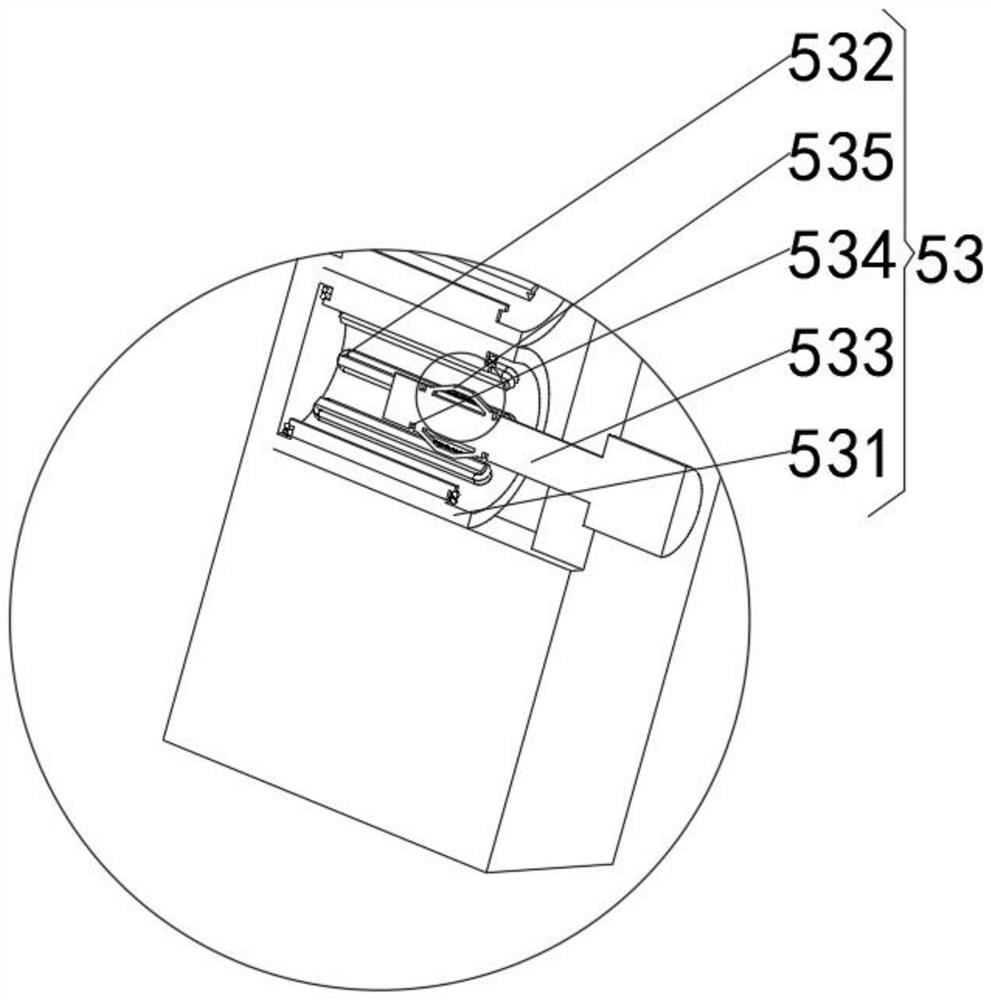

[0039] see Figure 1-7 , the present invention provides a technical solution: a textile dip-dyeing equipment, including a base plate 1, the symmetrical positions on both sides of the top of the base plate 1 are fixedly connected with protective baffles 2, and the middle position of the top of the base plate 1 is fixedly connected with a magnetic force electromagnet 3 The middle position of the outer wall on both sides of the magnetic force electromagnet 3 is fixedly connected with the track plate 4, the top front and back of the track plate 4 are fixedly connected with the power generation track 5, the top of the outer surface of the power generation track 5 is slidingly connected with the force plate 6, and the force plate 6 The friction bracket 7 is fixedly connected to the middle position of the sides far away from each other, the mounting plate 8 is fixedly connected to the side where the force applying plates 6 are close to each other, and the modulation rod 9 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com