Method for preparing low-sugar orange preserved fruits through enzymatic hardening intermittent vacuum sugar soaking

A technology of vacuum soaking sugar and citrus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

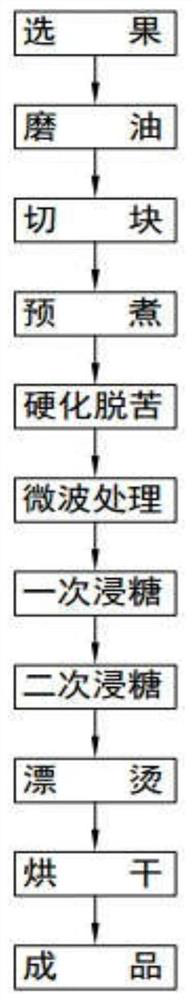

[0045] Such as figure 1 Shown, a kind of preparation method of enzymatic hardening intermittent vacuum naring peel sugar, comprises the following steps:

[0046] 1. Prepare pomelo peel and select pomelo peel requirements:

[0047] 1. Pick pomelo fruit, remove rotten fruit, wash and grind oil, peel and cut into pieces;

[0048] 2. The pomelo peels must be selected strictly, and the rotten, fruit pedicles, and flowering peels are not acceptable; it is best to use fresh peels that have not been debittered before, and more careful selection of pomelo peels that have been debittered before.

[0049] 3. The selected pomelo peels are flushed and dried twice, and the last time the water is shaken, it will stop after 5 minutes from the time when the water is cut off.

[0050] 2. Hardening and debittering treatment

[0051] 1. Precooking:

[0052] Boil the pomelo peel with water at a solid-to-liquid ratio of 1:7 for 5 minutes, and the pre-boiling temperature reaches 40°C;

[0053]...

Embodiment 2

[0076] A method for enzymatic hardening intermittent vacuum dipping to make orange peel low-sugar preserves, comprising the following steps:

[0077] 1. Prepare orange peels and select orange peels:

[0078] 1. Pick orange fruit, remove rotten fruit, wash and grind oil, peel and cut into pieces;

[0079] 2. The selection of orange peels must be strictly selected, and the peels of rotten, fruit pedicles, and flowering parts are not acceptable.

[0080] 3. The selected orange peels are flushed with water and dried twice, and the last time the water is shaken, it will stop for 5 minutes from the time when the water is cut off.

[0081] 2. Hardening treatment

[0082] 1. Precooking:

[0083] Boil the orange peel with water for 3 minutes according to the solid-to-liquid ratio of 1:7, and the pre-boiled end temperature reaches 50°C;

[0084] 2. Adjust PH value:

[0085] First use citric acid to adjust the pH value. The normal pH value of tap water is about 6.5-7. The hardening ...

Embodiment 3

[0101] A method for enzymatic hardening intermittent vacuum dipping to make kumquat low-sugar candied fruit, comprising the following steps:

[0102] 1. Raw material preparation and selection requirements:

[0103] 1. Select the intact kumquat fruit, remove the rotten fruit, wash and grind the oil, squeeze and remove the core;

[0104] 2. The treated fruit is first flushed and dried twice, and the last time the water is shaken, it will stop for 5 minutes from the time when the water is cut off.

[0105] 2. Hardening and debittering treatment

[0106] 1. Precooking:

[0107] Boil kumquats with water at a solid-to-liquid ratio of 1:2 for 10 minutes, and the temperature at the end of pre-boiling is 50°C;

[0108] 2. Adjust PH value:

[0109] First use citric acid to adjust the pH value. The normal pH value of tap water is about 6.5-7. The hardening and debittering treatment requires a pH value between 4-5; (about 4.5; use pH test paper to detect the pH value), and control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com