Method for manufacturing board by using saw dust

A wood chip and board technology, applied in wood treatment, impregnated wood, wood impregnation, etc., can solve the problems of low added value of wood chip processing, difficulty in meeting wood demand, and low utilization rate, so as to increase added value and enhance the degree of mutual integration and fusion speed, the effect of maintaining the original performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

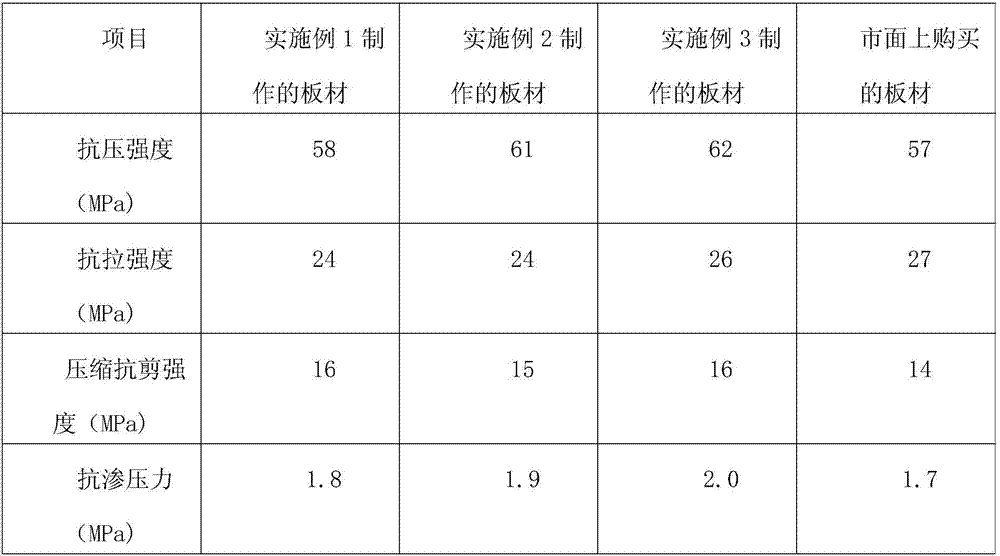

Examples

Embodiment 1

[0021] A method for making boards from sawdust, comprising the steps of:

[0022] (1) Raw material pretreatment: raw material selection: choose sawdust from wood processing plant as raw material to remove impurities; use a pulverizer to crush the sawdust, sieve and control the crushed particle size to 3mm according to needs; put the sawdust into the drying box, and control the drying The temperature is 80°C, and the moisture in the sawdust is removed by drying. The moisture content of the dried sawdust is 42%; the dried sawdust is placed in the impregnating agent and soaked for 8 hours while stirring. The temperature of the impregnating agent is 72°C, and then deionized Rinse with water until neutral, filter with suction, dry for the second time until the water content is 9%, crush and sieve again to obtain primary modified wood chips; put the primary modified wood chips into a closed pyrolysis furnace, and protect Gas for pyrolysis protection, the temperature is controlled at...

Embodiment 2

[0027] A method for making boards from sawdust, comprising the steps of:

[0028] (1) Raw material pretreatment: raw material selection: choose sawdust from wood processing plant as raw material to remove impurities; use a pulverizer to crush the sawdust, sieve and control the crushed particle size to 4mm according to needs; put the sawdust into the drying box, and control the drying The temperature is 105°C, and the moisture in the sawdust is removed by drying. The moisture content of the dried sawdust is 45%; the dried sawdust is placed in the impregnating agent and soaked for 9 hours while stirring. The temperature of the impregnating agent is 76°C, and then deionized Rinse with water until neutral, filter with suction, dry for the second time until the water content is 11%, crush and sieve 95 mesh again to obtain primary modified wood chips; put the primary modified wood chips into a closed pyrolysis furnace to protect Gas for pyrolysis protection, the temperature is contr...

Embodiment 3

[0033] A method for making boards from sawdust, comprising the steps of:

[0034](1) Raw material pretreatment: raw material selection: choose sawdust from wood processing plant as raw material to remove impurities; crush the sawdust with a crusher, screen and control the crushed particle size to 5mm according to needs; put the sawdust into the drying box and control the drying The temperature is 130°C, and the moisture in the sawdust is removed by drying. The moisture content of the dried sawdust is 49%; the dried sawdust is placed in the impregnating agent and soaked for 10 hours while stirring. The temperature of the impregnating agent is 80°C, and then deionized Rinse with water until neutral, filter with suction, dry for the second time until the water content is 13%, crush and sieve again to obtain primary modified wood chips; put the primary modified wood chips into a closed pyrolysis furnace, and protect Gas for pyrolysis protection, the temperature is controlled at 35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com