Multifunctional plating assistant additive for hot-dip metal plating and preparation method thereof

An additive and multi-functional technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problem of shortening the drying time of plating flux, affecting the effect of hot-dip plating, and reducing the adhesion of plating flux and other problems, to achieve the effect of shortening the immersion plating time, improving the uniformity and continuity of adhesion, and good explosion-proof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

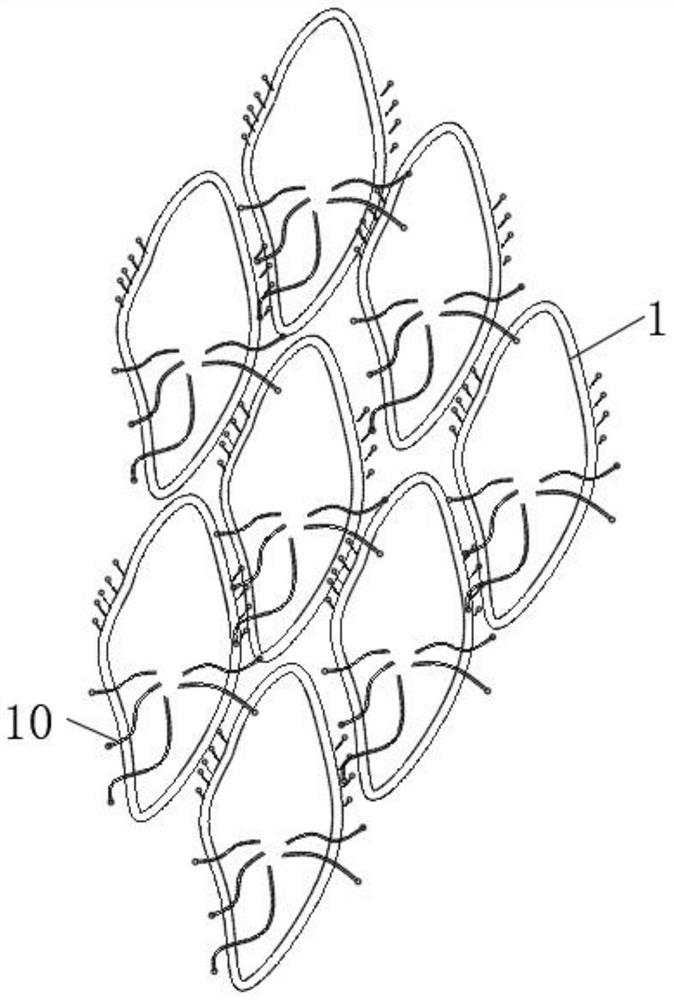

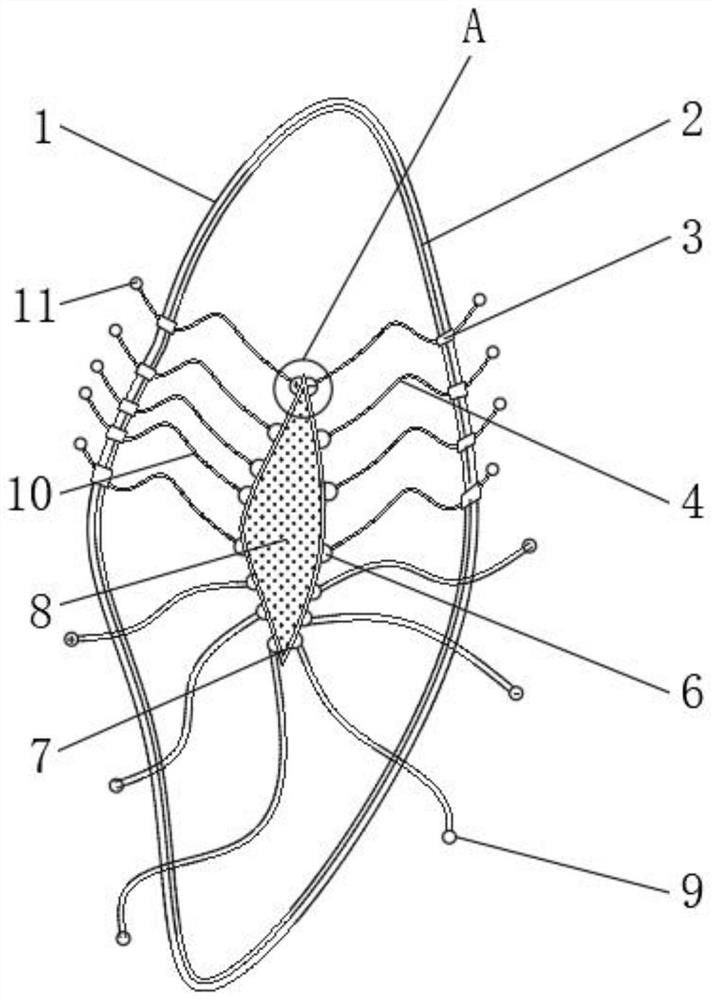

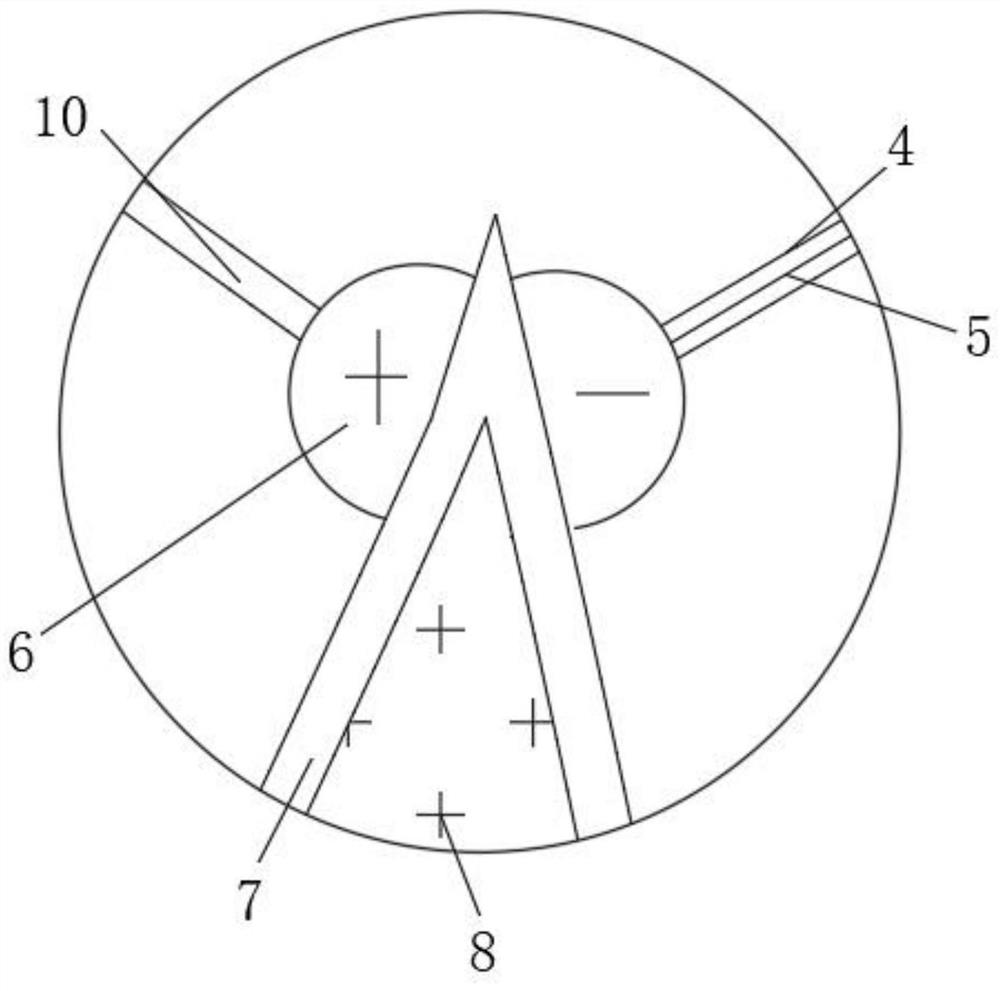

[0052] see Figure 1-4 , a multifunctional flux additive for hot-dip metal plating and a preparation method thereof, its formula components include Ce2O30.40%-0.45%, Al4%-6%, Mn0.5%-1%, Mg1%-1.5%, Si0.3%-0.6%, Sn2%-4%, Bi0.3%-0.4%, quaternary ammonium radical equivalent concentration is 0.1-2mol / L, polyoxyethylene equivalent concentration is 0.5-5mol / L and 7%-15% Explosion-proof factor, the remainder is Zn.

[0053] Also includes its preparation method:

[0054] S1: dissolve;

[0055] Dissolve Ce2O3, Al, Mn, Mg, Si, Sn, Bi, Zn, quaternary ammonium root equivalent concentration, non-ionic surfactant and 7%-15% explosion-proof factor in deionized water.

[0056] S2: constant volume;

[0057] When using a volumetric flask to configure the dissolved mixed solution with accurate concentration, when the added solution is 1 to 2 cm away from the scale line, use a dropper with a rubber tip to suck the solution into the volumetric flask, and the line of sight is at the lowest phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com