Explosion-proof lamp connector

An explosion-proof lamp and explosion-proof rubber technology, which is applied in the direction of lighting devices, lighting device parts, lighting auxiliary devices, etc., can solve the problems of increasing the production cost of lamps, large volume, convenience of explosion-proof lamps, limited applicability and variability of lamps, etc. problem, to achieve the effect of convenient serial connection change application, small overall size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

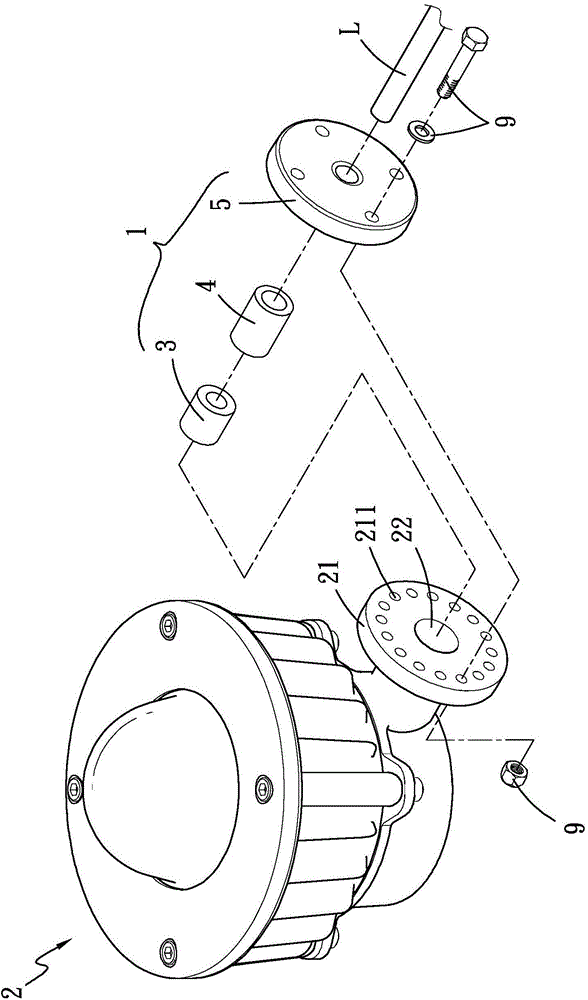

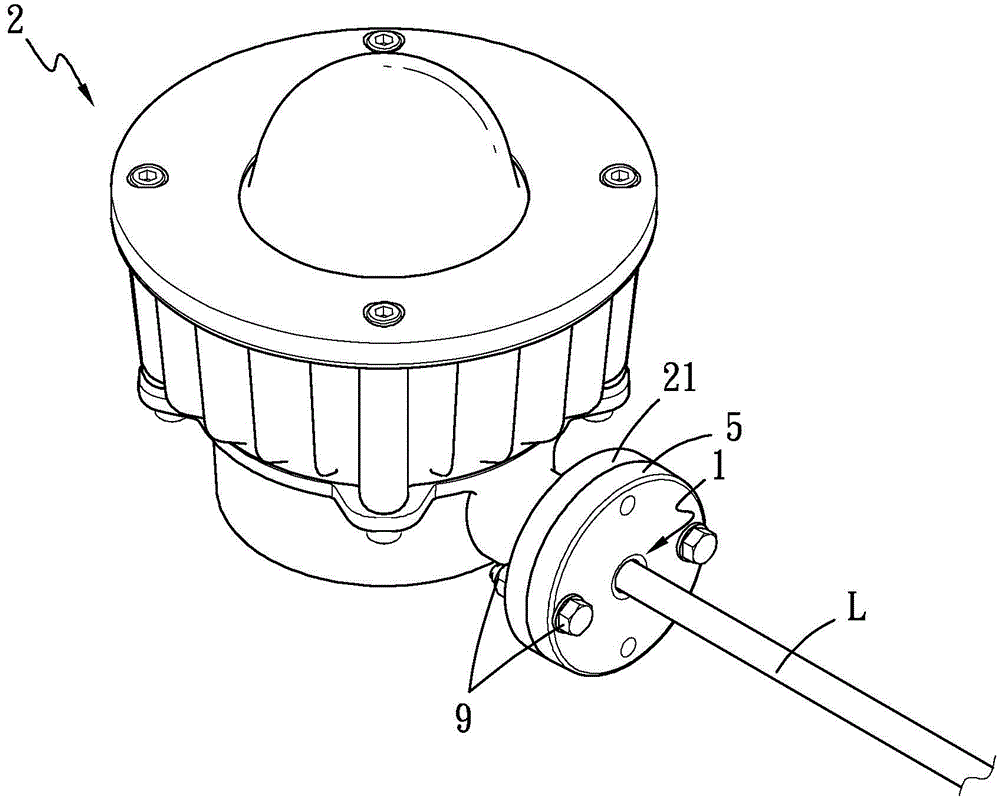

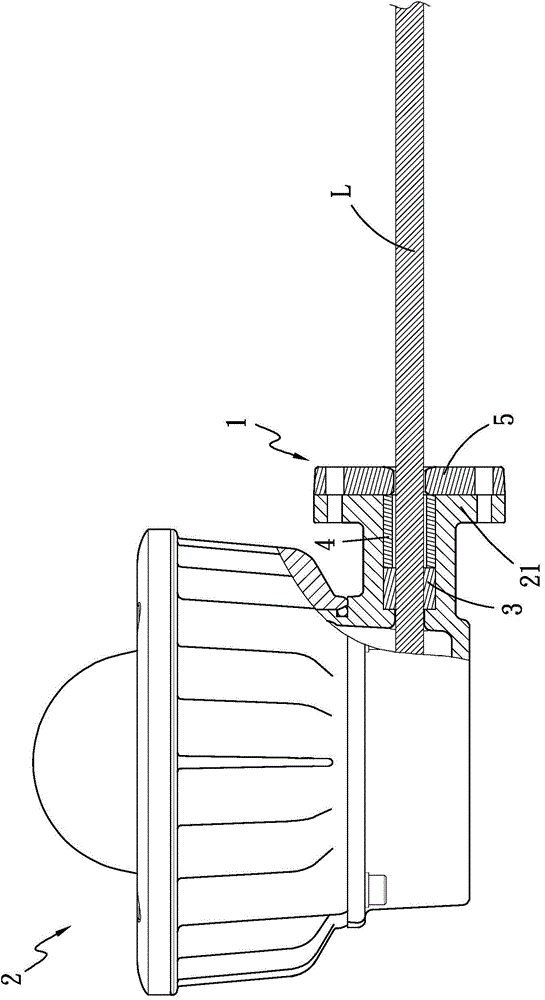

[0041] Below in conjunction with the accompanying drawings, explain in detail how the structure of the present invention is combined and used. It should be easier to understand the purpose, technical content, characteristics and effects of the present invention. Before describing the present invention in detail, it is necessary to first It should be noted that in the following description, the implementation of different aspects of the same components is represented by the same symbols, and the explosion-proof lamp connector 1 of the present invention is suitable for passing through the cable L and connecting to an explosion-proof Lamp 2 (see figure 1 ) at a through hole 22 of a joint part 21, the joint part 21 is used for connecting another explosion-proof lamp in series or for direct or indirect fixing on the wall, and the through hole 22 is for the cable L to be routed to the explosion-proof lamp Used for the electronic control module inside the lamp 2.

[0042] Please ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com