Gas tank storing room

A technology for storage rooms and gas tanks, applied in gas/liquid distribution and storage, fixed-capacity gas storage tanks, pressure vessels, etc., can solve the threat to the life and property safety of practitioners, no leakage and explosion-proof measures, and no warehouse Centralized storage and other issues to achieve the effect of preventing production safety accidents, avoiding random handling, and ensuring the safety of life and property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

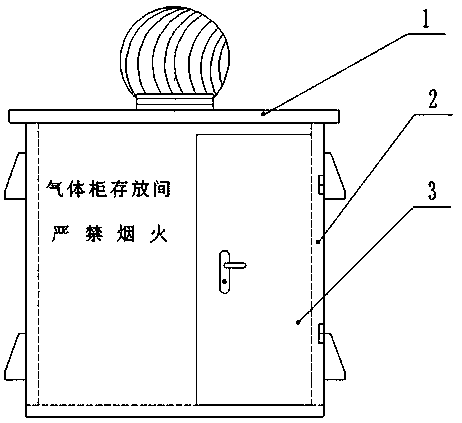

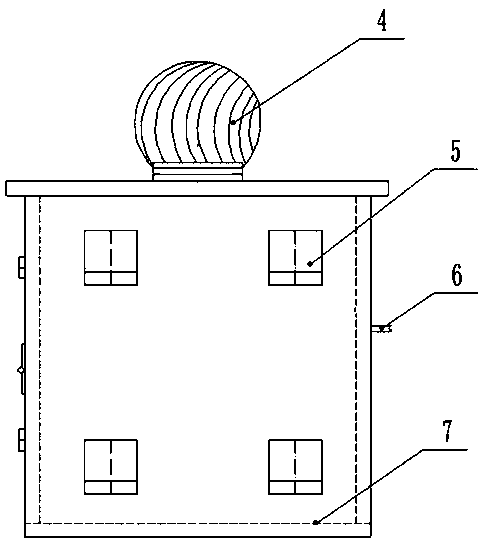

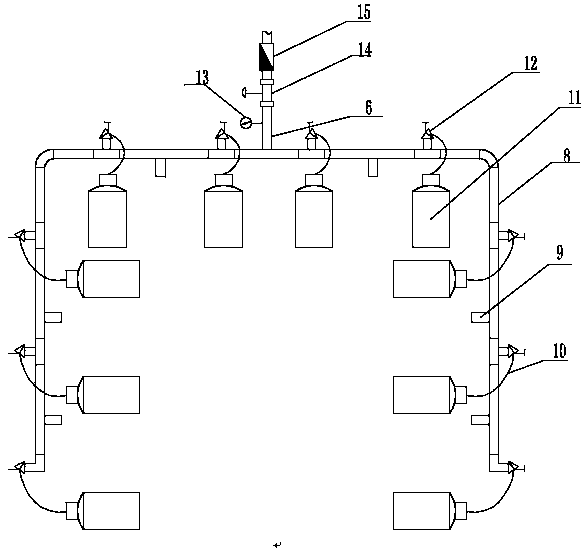

[0016] Such as figure 1 , 2 , 3, a kind of gas tank storage room of the present invention comprises a board room body, and a confluence main pipe 8 is set up in the board room body, and several gas storage tanks 11 are placed around the confluence main pipe 8, and the connection between the gas storage tanks 11 and the confluence main pipe 8 An air guide hose 10 is connected between them, and an angle valve 12 is arranged on the air guide hose 10. The middle part of the confluence main pipe 8 is connected with an air supply main pipe 6 extending out of the board room body. The air supply main pipe 6 is provided with a pressure gauge 13 and a main valve 14. And fire stop valve 15, have rainproof ventilating window 5 and fireproof insulation door 3 on the board room body side wall, the board room top is provided with air vent, and described air vent place is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com