Synthesis method and synthesis container of phosphorus-silicon-cadmium polycrystal

A synthesis method and polycrystal technology are applied in the field of preparation methods and used containers, which can solve the problems that the synthesis cannot be guaranteed to be sufficient and complete, the single crystal cannot satisfy the device fabrication, and the materials cannot be sufficiently mixed, etc., so as to achieve convenient mechanical oscillation and good explosion-proof performance. function, the effect of reducing the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

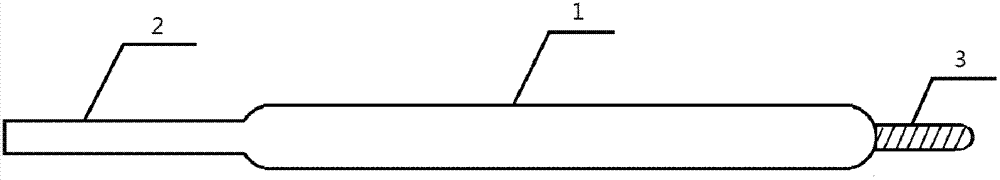

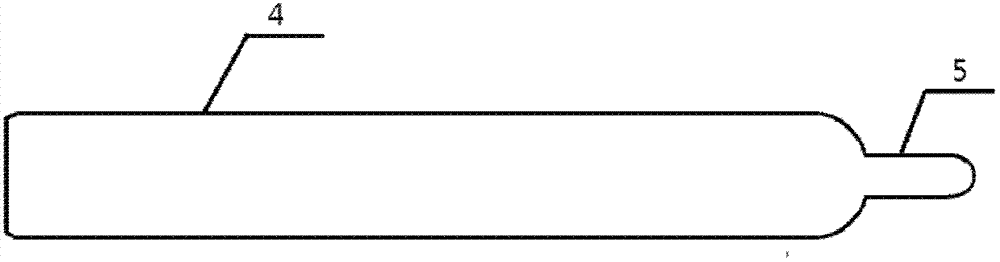

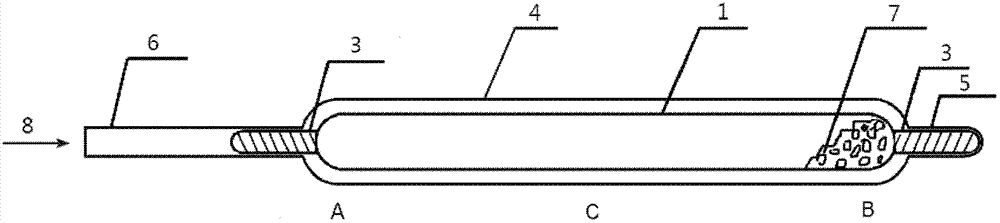

[0038] In this embodiment, the shape and structure of the synthetic container are as Figure 4 As shown, it is composed of an inner crucible 1 and an outer crucible 4. The initial state of the inner crucible is a quartz tube with one end open and one end closed, the closed end is provided with a support rod 3, and the open end is connected with a feed pipe 2, such as figure 1 shown. The initial state of the outer crucible 4 is a quartz tube with one end open and one end closed by the support sleeve 5. Its inner diameter is greater than the outer diameter of the inner crucible, and its length is greater than the length of the inner crucible. Crucible set up to match the support rods, such as figure 2 shown.

[0039] The working state of the inner crucible is a quartz tube with both ends closed, and the two closed ends are provided with support rods 3. The working state of the outer crucible 4 is a quartz tube with both ends closed by support sleeves 5. Their assembly The m...

Embodiment 2

[0043] In this embodiment, the raw materials silicon (Si), cadmium (Cd), and phosphorus (P) used are all 6N grades. When batching, the molar ratio of each raw material is Si:Cd:P=1:1:2, and the amount of phosphorus The amount added increases by 0.5% on the basis of the weight calculated by the above-mentioned molar ratio. According to the above-mentioned ratio, cadmium is 11.76145 grams, silicon is 2.93980 grams, and phosphorus is 6.51391 grams.

[0044] The synthesis container used for synthesis is the synthesis container described in Example 1, and the structure of the two-zone heating tube furnace used for synthesis is shown in Figure 5 , Figure 6 and Figure 7 , including a furnace body 12, heating elements 13 installed at both ends of the furnace body, and a bracket 17 hinged to the furnace body through a hinge 18. During synthesis, the furnace body can be tilted and rotated as required. The ends are high temperature zone I and high temperature zone II respectively, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com