Deadweight flattening-type dehydrator for dehydration section of laver one-step processing unit

A dehydration device and rack technology, applied in the direction of dehydration preservation of fruits/vegetables, application, food processing, etc., can solve the problems of unclean dehydration, increase of drying energy consumption, etc., to reduce production costs and energy consumption, and shorten drying time , the effect of reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

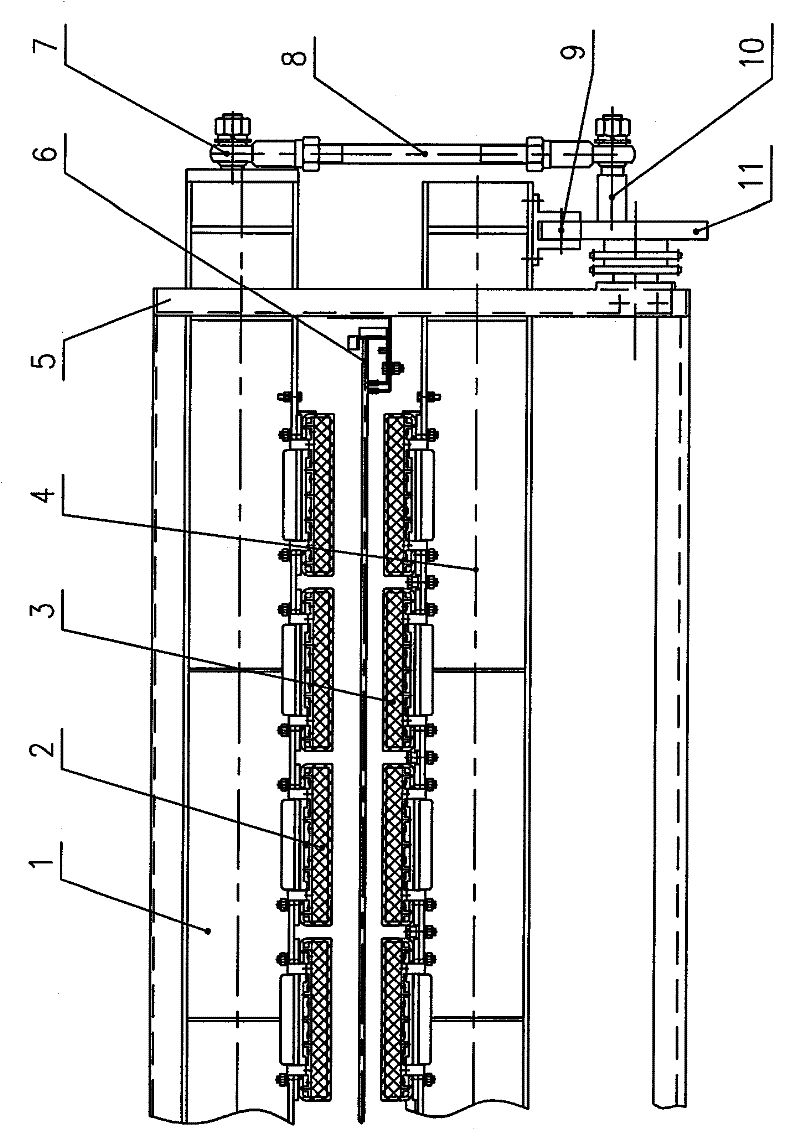

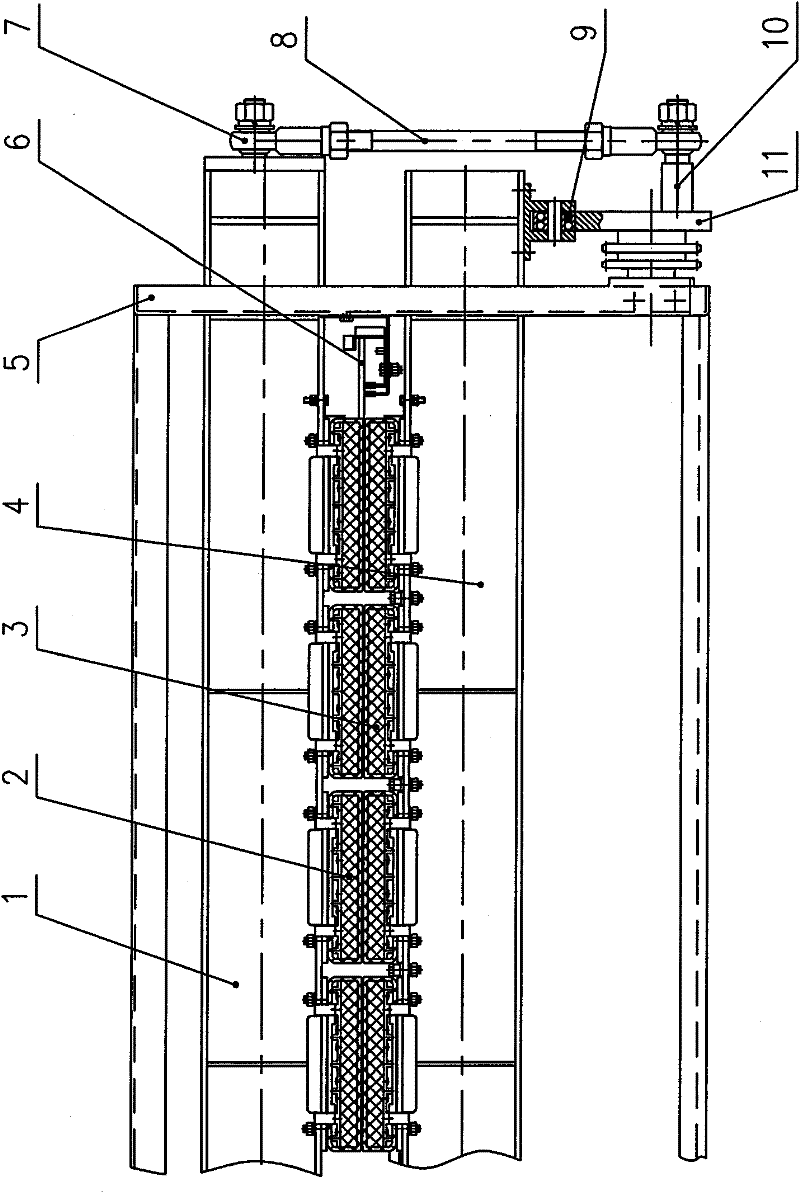

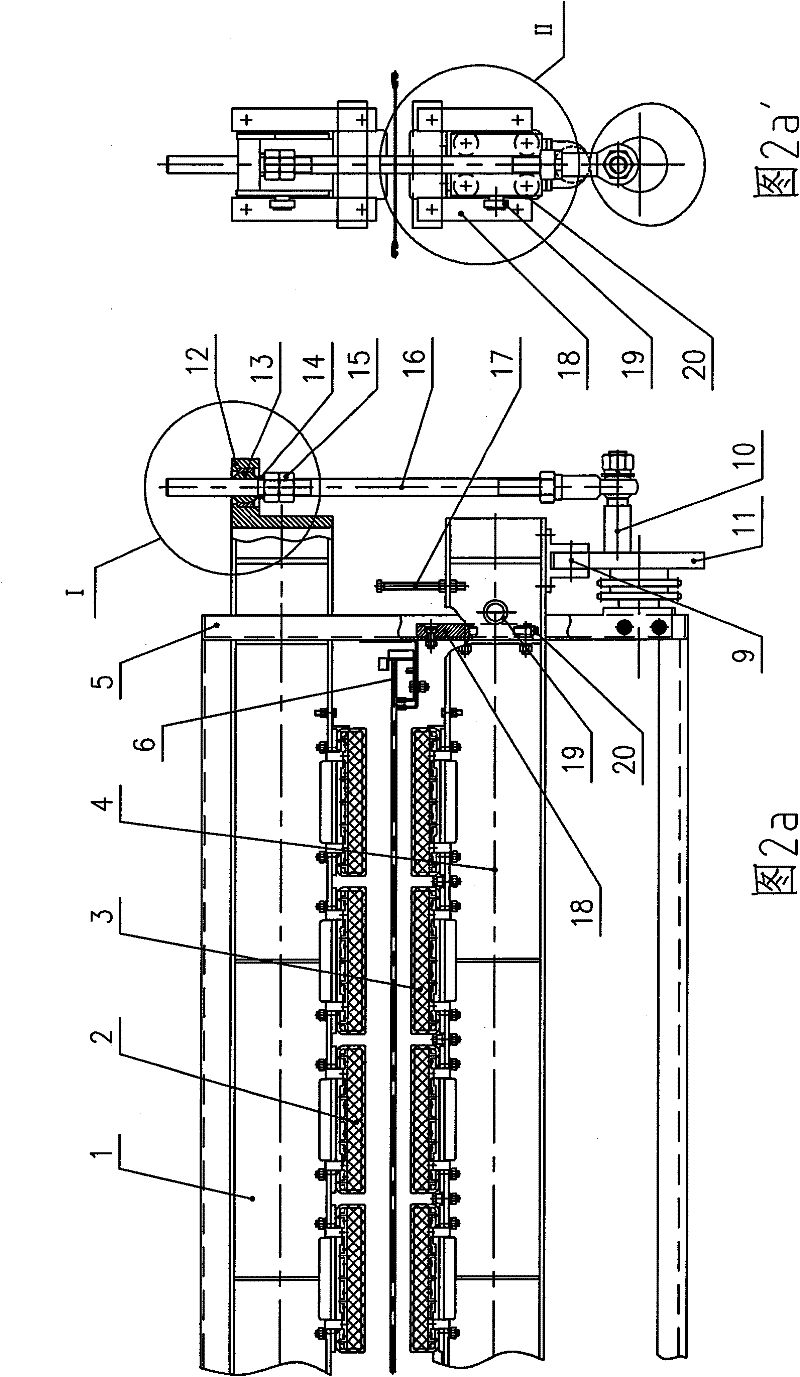

[0039] Such as Figure 2a As shown, the present invention provides a self-weight rolling type vegetable cake dehydration device. In order to prolong the dehydration time of vegetable cakes and properly and effectively control the dehydration time, the device changes the mutual constraint relationship of the existing dehydration devices and saves The straight shank joint bearing 7 located at the upper end of the original tie rod 8 replaces the original tie rod 8 with a top rod 16 with a smooth outer circle at the upper end, and a bracket or bearing seat 12 is added at the end of the upper dehydration beam 1, and the bracket or bearing seat 12 is inlaid with Spherical joint bearing 13, the upper end or first end of push rod 16 passes through the inner hole of spherical joint bearing 13, and the lower end or second end of push rod 16 can be connected with the eccentric wheel shaft 10 of eccentric cam 11 for example by joint bearing , and the eccentric cam 10 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com