An industrial pure pu foam alcoholysis recovery method and special recovery feeding device

The technology of a feeding device and a recycling method is applied in the field of industrial pure PU foam alcoholysis recovery and special recycling feeding device, which can solve the problems of slow recycling feeding and high polyol VOC index, and achieve improved quality, accurate feeding, Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

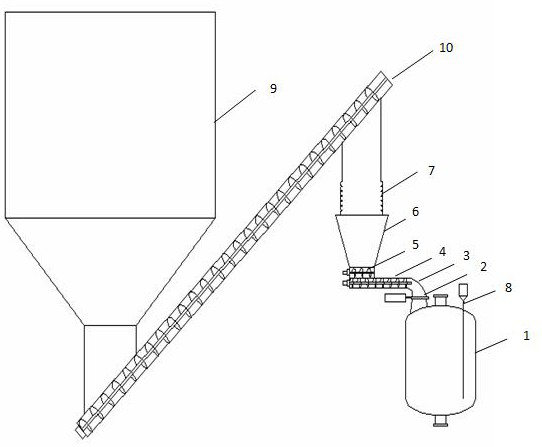

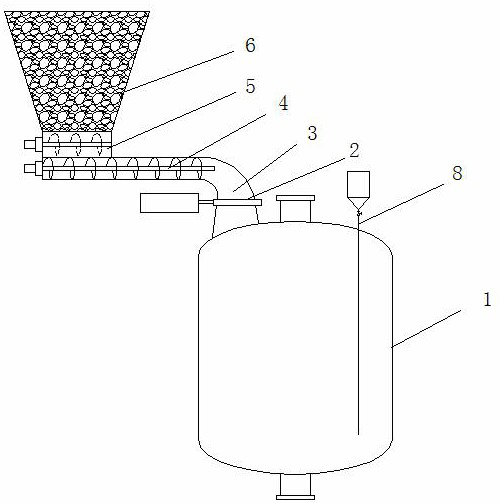

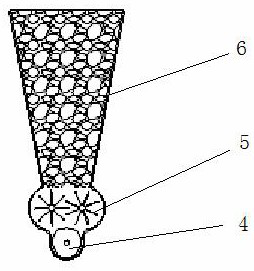

[0044] Example 1, see figure 1 , 2 3. According to the design requirements, select the weighing bin 9 and the screw conveyor 10 of appropriate specifications, both of which are conventional equipment, and connect the two; connect the screw conveyor 10 with the feed funnel 6 through the soft connection 7 Auxiliary feed double-screw feed conveyor 5 is installed at the lower end of feeding funnel 6, and auxiliary feed double-screw feed conveyor 5 is delayed compared to screw conveyor 10; The main feeding screw conveyor 4 is connected, the main feeding screw conveyor 4 is connected with the feeding variable diameter elbow 3, the diameter of the interface between the two is Φ200, the inner wall of the feeding variable diameter elbow 3 is polished and sprayed with Teflon coating layer, the surface energy of the inner wall is lower than 20dyn / cm; the feed reducing elbow 3 is communicated with the reactor 1 through the pneumatic gate valve 2, and the interface between the feed reduci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com