Preparation method of pentaerythritol tetraacetate

A pentaerythritol tetraacetate and pentaerythritol technology are applied in the field of preparing and synthesizing pentaerythritol tetraacetate, which can solve the problems of high temperature performance damage of oil products, and achieve the effects of low product, low hydroxyl value and low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

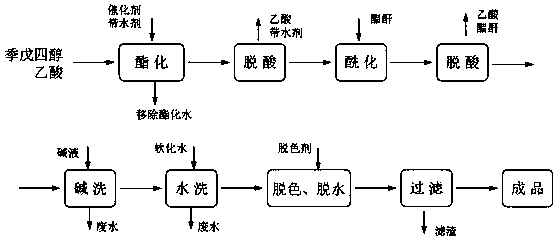

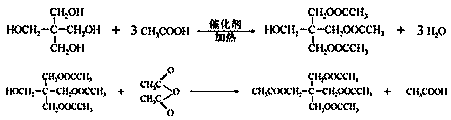

Method used

Image

Examples

Embodiment 1

[0033] Add 1.0kg of solid pentaerythritol (a sample provided by Jiangsu Yixing Sanmu Chemical Industry Co., Ltd.) and 2.5kg of industrial acetic acid into a 5L reactor (equipped with a packing column), start stirring, then add 7g of concentrated sulfuric acid and 400mL of isopropyl acetate, and heat up. Start the esterification reaction. The esterification water produced during the reaction process is continuously separated from the lower part of the water separator after being condensed with the evaporation of isopropyl acetate, and the isopropyl acetate in the upper layer is refluxed to the esterification kettle. The esterification was carried out for 8 hours, and basically no water was generated in the reaction, and the esterification reaction reached the end point, and the reaction was stopped.

[0034] The material is transferred to the deacidification kettle, and the vacuum pump is turned on to remove excess acetic acid and isopropyl acetate, which can be reused in the a...

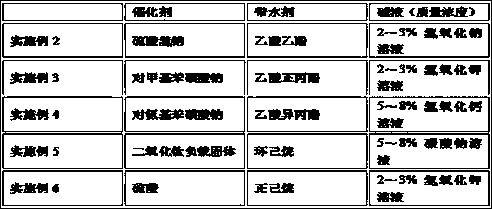

Embodiment 2~6

[0038] Embodiment 2~6: with reference to embodiment 1, catalyst, water-carrying agent, lye parameter are as shown in the table below:

[0039]

[0040] The relevant index of the pentaerythritol tetraacetate of gained is shown in the following table:

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com