Patents

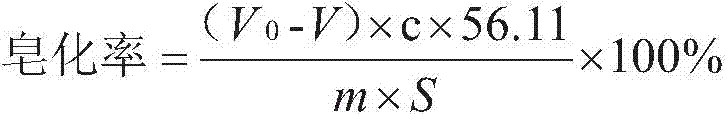

Literature

50 results about "Pentaerythritol tetranitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pentaerythritol tetranitrate (PETN), also known as PENT, PENTA, TEN, corpent, or penthrite (or—rarely and primarily in German—as nitropenta), is an explosive material. It is the nitrate ester of pentaerythritol, and is structurally very similar to nitroglycerin. Penta refers to the five carbon atoms of the neopentane skeleton. PETN is a powerful explosive material with a relative effectiveness factor of 1.66. When mixed with a plasticizer, PETN forms a plastic explosive. Along with RDX it is the main ingredient of Semtex.

Method for preparing high-quality energetic crystal material fine particles

ActiveCN102320903AReduce crystal defectsReduced Shockwave SensitivityExplosive working-up apparatusShock waveFOX-7

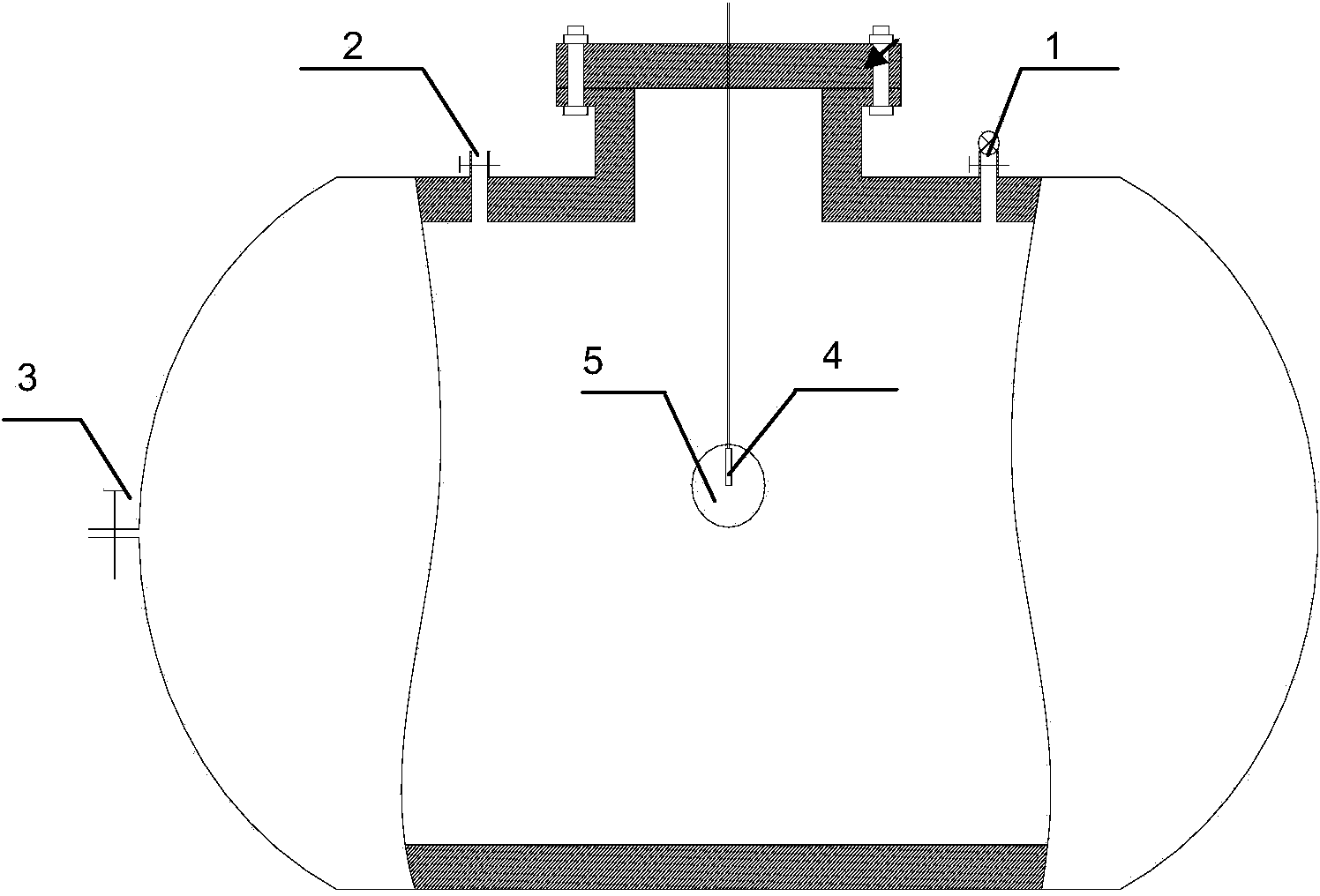

The invention relates to a method for preparing high-quality energetic crystal material fine particles. Various high-quality energetic crystal material fine particle products, such as pentaerythritol tetranitrate (PETN), cyclotrimethylene trinitramine (RDX), cyclotetramethylenetetranitramine (HMX), hexanitrohexaazaisowurtzitane (CL-20), DADNE (FOX-7), ammonium perchlorate (AP), and the like can be prepared by adopting an ultrasound solvating-out crystallization method in the traditional solvating-out crystallization process. The high-quality energetic crystal material fine particle product prepared by the preparation method disclosed by the invention has subglobular particle form, narrow granularity distribution, average particle diameter of 5-50 microns or so, transparent crystals, high particle density, crystal theoretical density of more than 99.9 percent and obviously reduced shock wave sensitivity and is used for pouring or pressing PBX (Plastic-bonded explosives). The method for preparing the high-quality energetic crystal material fine particles has the advantages of simple process flow and mild reaction conditions and is suitable for mass industrialized production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

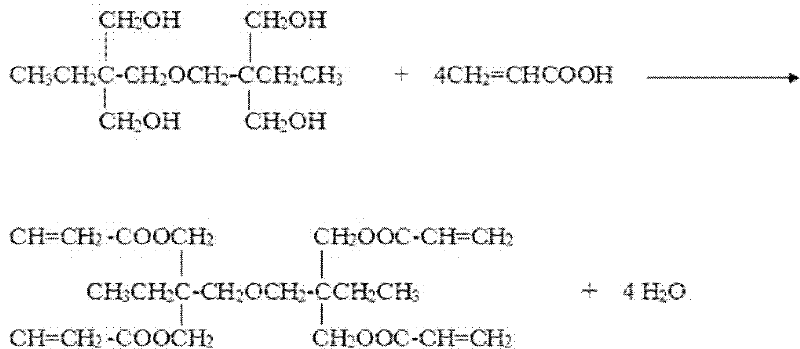

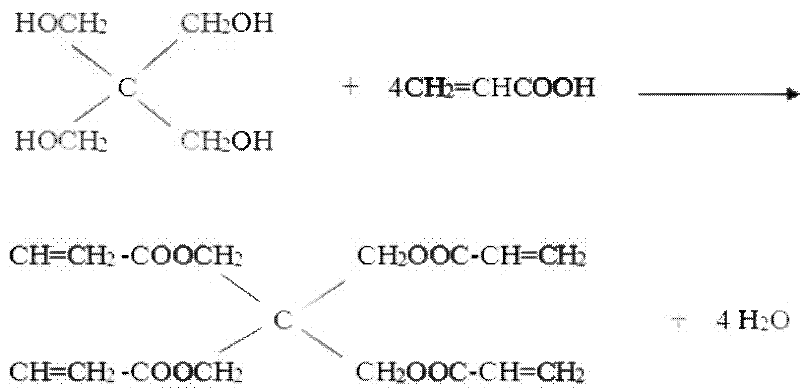

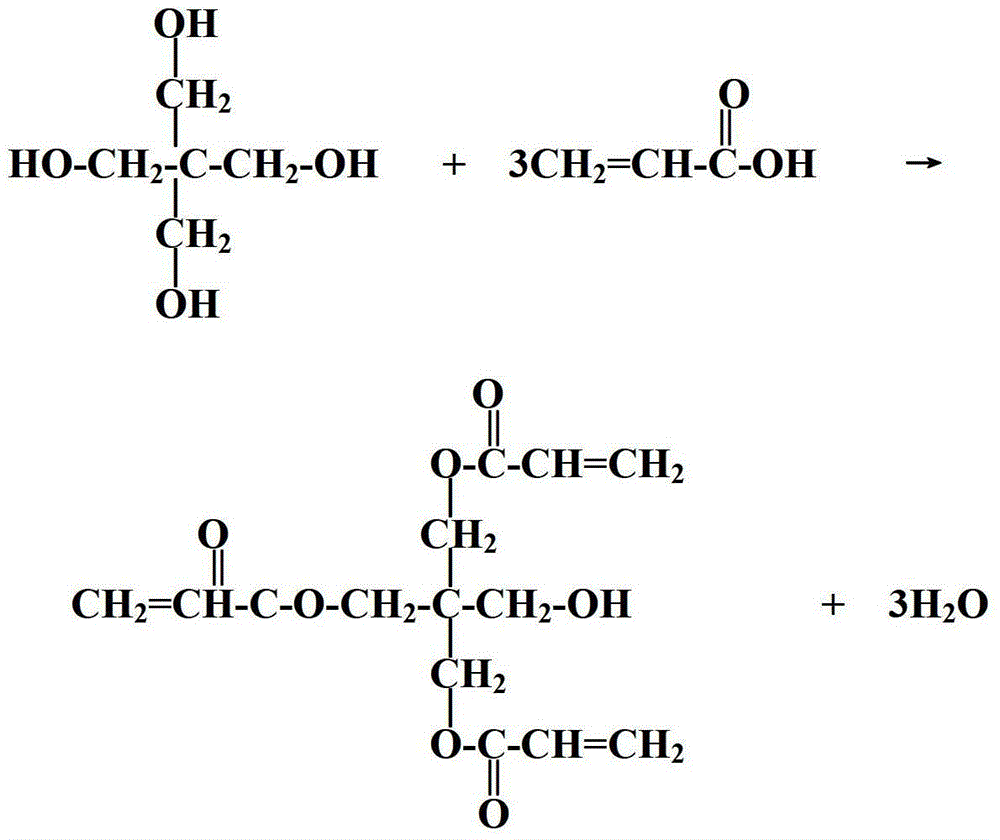

Cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester

ActiveCN102643197ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSorbentSolvent

The invention belongs to the field of photo-curing material, and relates to a cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester. The method specifically comprises the following steps of: (1) dehydrating di-trimethylolpropane / pentaerythritol, crylic acid, catalyst, solvent, polymerization inhibitor and antioxygen by means of esterification and backflow; (2) adding sheet alkali and a small quantity of water to neutralize; (3) adding magnesium polysilicate adsorbent to adsorb and neutralize the generated salt; (4) dehydrating in a pressure reducing way, and removing solvent; (5) carrying out filter pressing, filtering out the magnesium polysilicate and salt adsorbed by the magnesium polysilicate; (6) adding alkaline calcium bentonite and calcium oxide, to remove color, trace moisture and trace acid; (7) carrying out filter pressing; and (8) detecting the indexes of a product. The invention belongs to a cleaning production method for the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester, which is good in economic benefit and environmental benefit, so that the problem of organic waste water pollution when the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester is produced can be basically solved.

Owner:JIANGSU LITIAN TECH

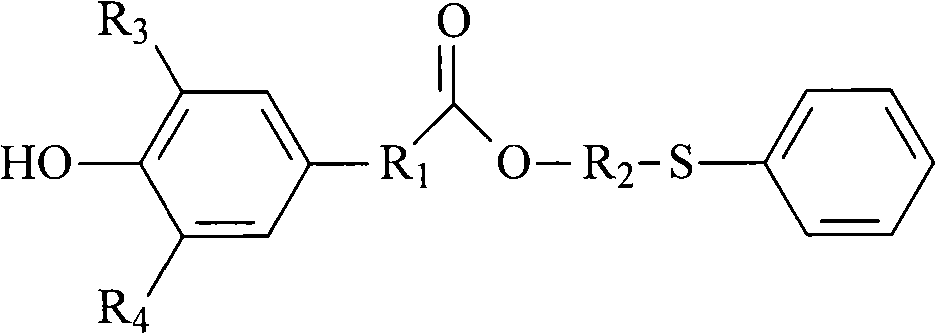

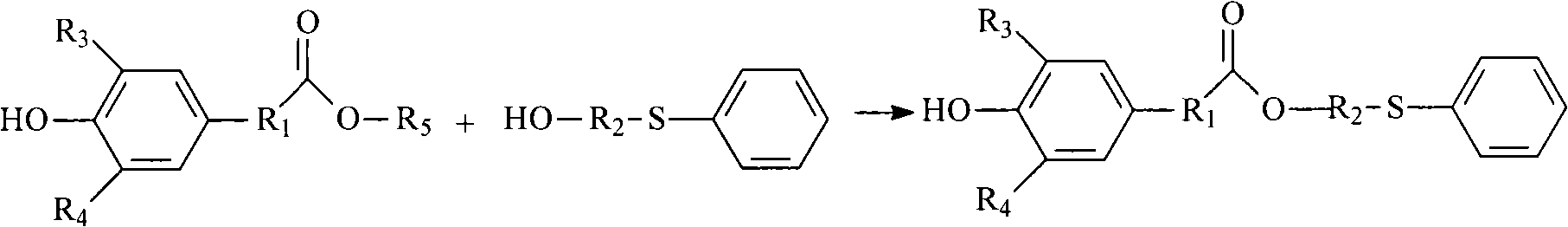

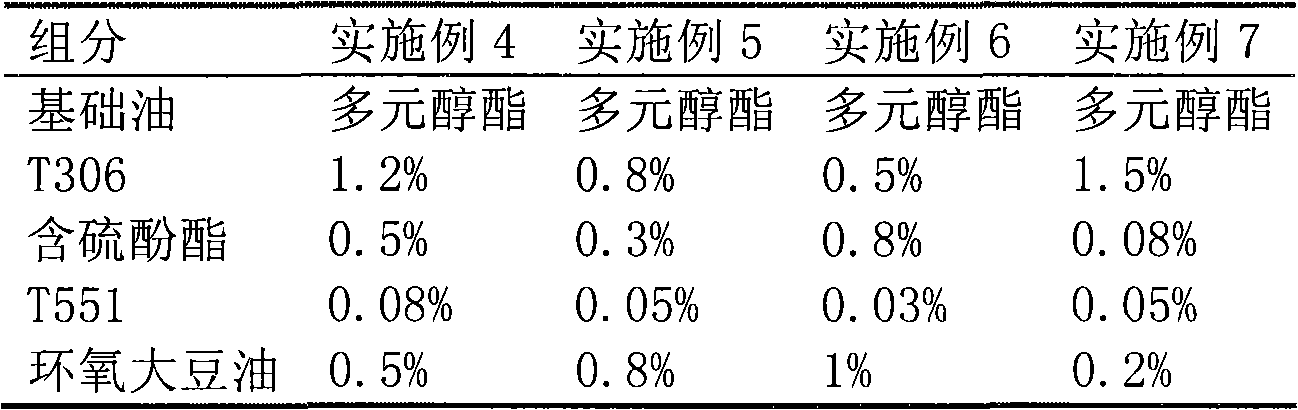

Refrigerator oil composition

InactiveCN101851545AImprove Oxidation StabilityProlonged oxidation induction periodAdditivesPolyolesterPentaerythritol

The invention relates to a refrigerator oil composition, which comprises polyol ester, (3,5-dialkyl-4-hydroxyphenyl) carboxylic thiophenyl alkyl ester, an antiwear agent, a metal passivator and an acid catching agent, wherein the polyol ester is pentaerythritol tetranitrate generated by reacting pentaerythritol with a mixture of isononanoic acid and diethyl caproic acid. The refrigerator oil composition provided by the invention has excellent oxidation stability. Compared with that of the refrigerator oil using the conventional antioxidant, the oxidative induction time of the refrigerator oil composition is obviously prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

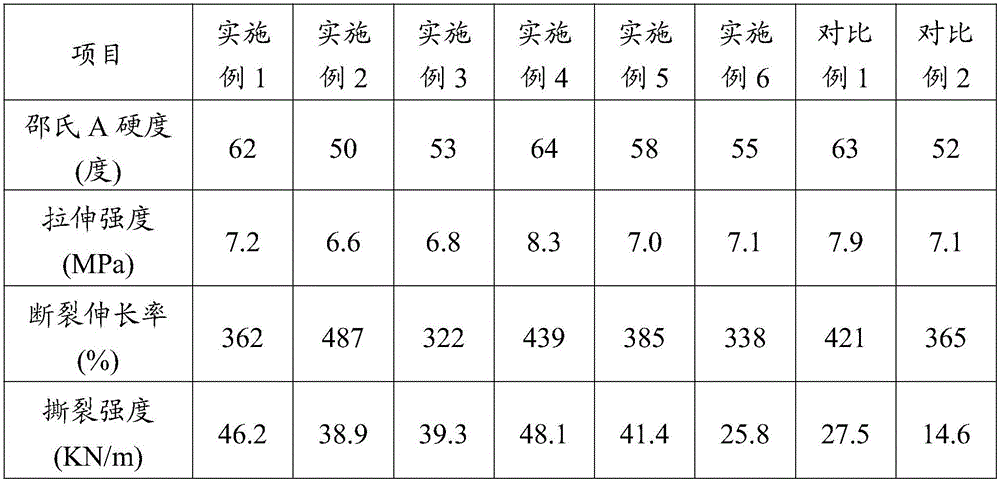

High-tearing-intensity high-temperature vulcanized silicon rubber, and preparation method and application thereof

The invention relates to high-tearing-intensity high-temperature vulcanized silicon rubber, and a preparation method and application thereof. Preparation raw materials of the high-tearing-intensity high-temperature vulcanized silicon rubber comprise the following ingredients including vulcanizing-agent-free mixing materials, polyvinyl cross linking auxiliary agents and vulcanizing agents; the vulcanizing-agent-free mixing materials comprise the following ingredients including methyl vinyl silicon rubber raw rubber, filling materials and structuring prevention agents; the polyvinyl cross linking auxiliary agents are selected from at least one from triallyl isocyanurate, tetravinyl tetramethylcyelo tetrasiloxane, ethoxylated trimethylolhexane triacylate, ethoxylated pentaerythritol Tetraacrylate, ditrimethylolpropane acrylate, propoxylated pentaerythritol tetraacrylate, dipentaerythritol pentaacrylate, propoxylated glyceryl triacrylate, pentaerythritol tetraacrylate, tri(trimethylolpropane) tetraacrylate, propoxylated tri(trimethylolpropane) tetraacrylate and triallyl cyanurate.

Owner:GUANGZHOU BAIYUN CHEM IND

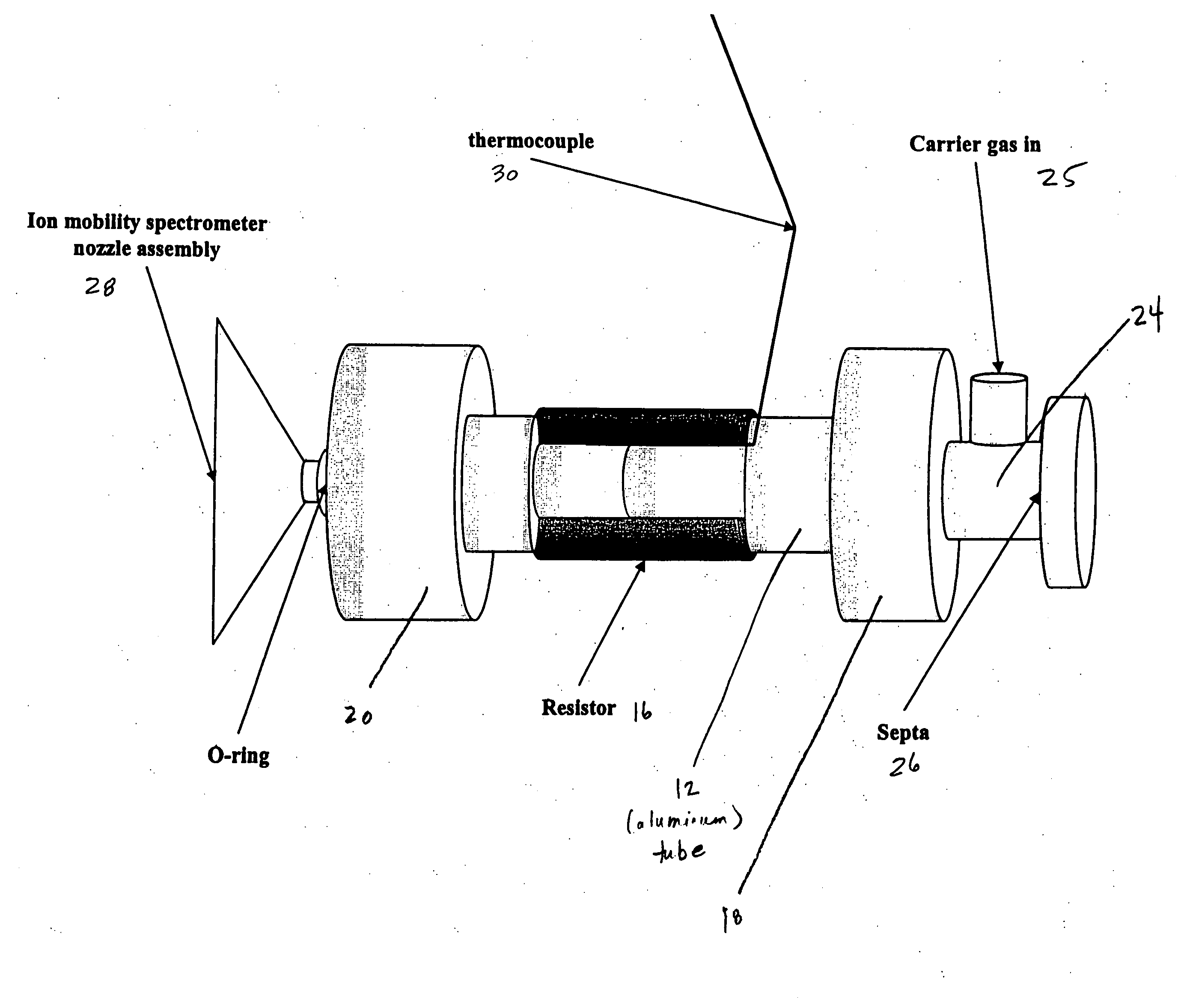

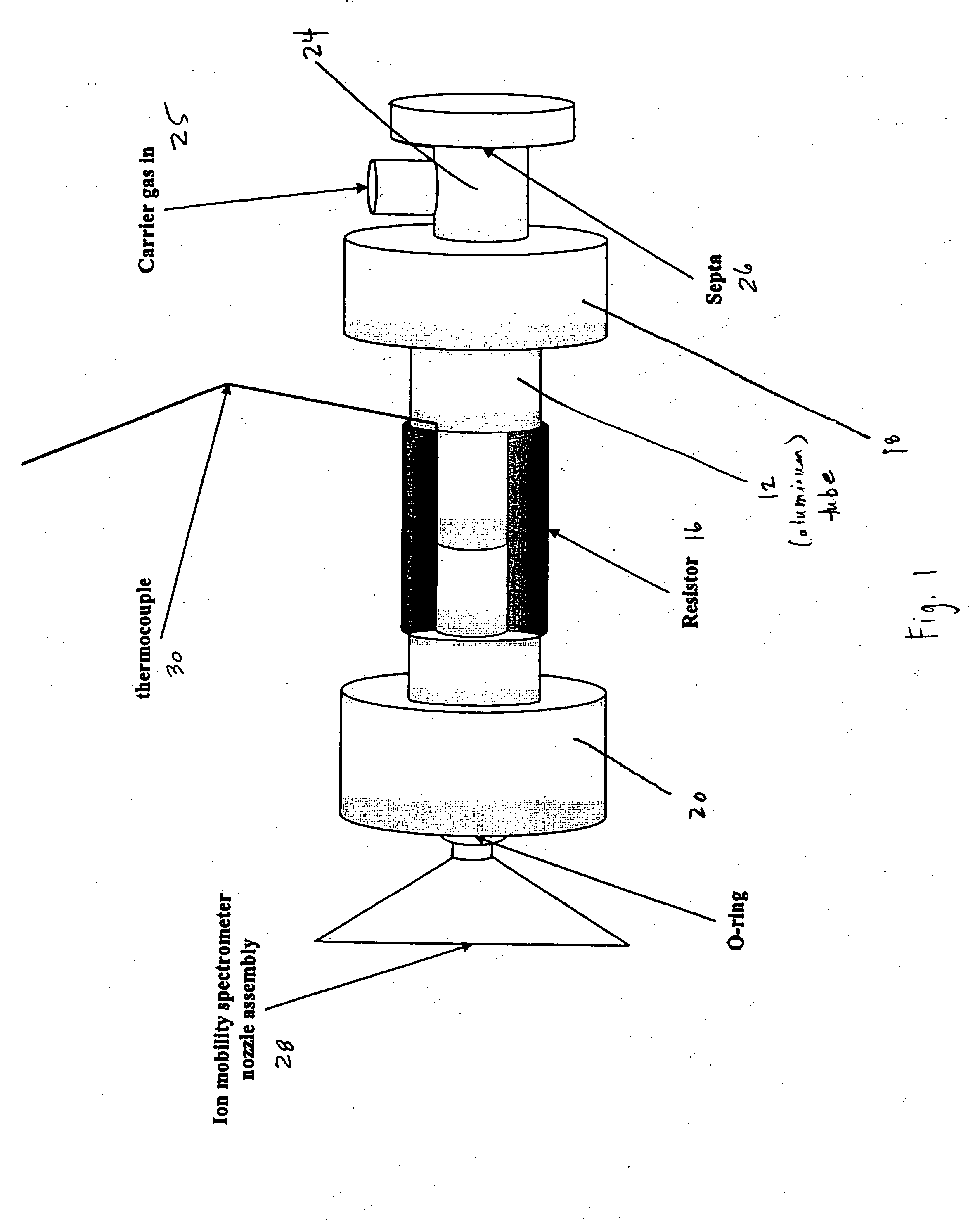

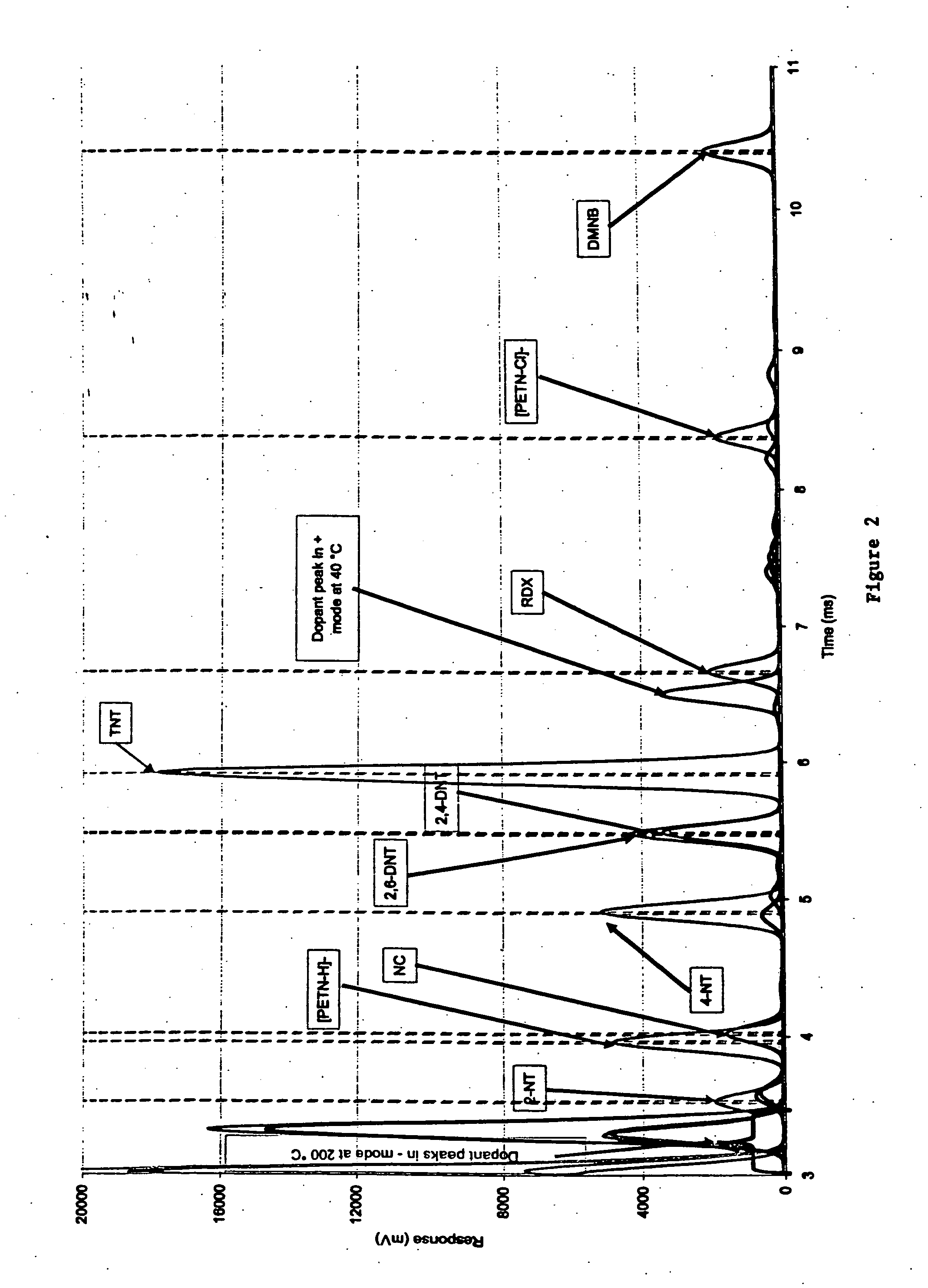

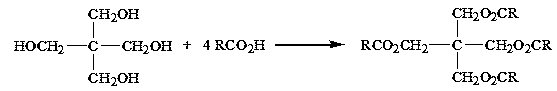

Method and apparatus for Detecting Explosives

An interface that couples SPME to IMS has been constructed and evaluated for the detection of the following detection taggants: 2-nitrotoluene (2-NT), 4-nitrotoluene (4-NT), and 2,3-dimethyl-2,3-dinitrobutane (DMNB). The interface was also evaluated for the following common explosives: smokeless powder (nitrocellulose, NC), 2,4-dinitrotoluene (2,4-DNT), 2,6-dinitrotoluene (2,6-DNT), 2,4,6-trinitrotoluene (2,4,6-TNT), hexahydro-1,3,5-trinitro-s-triazine (RDX), and pentaerythritol tetranitrate (PETN). The resultant SPME-IMS interface was found to extract volatile constituent chemicals and detection taggants in explosives from a headspace for subsequent detection in a simple, rapid, sensitive, and inexpensive manner.

Owner:FLORIDA INT UNIV RES FOUND

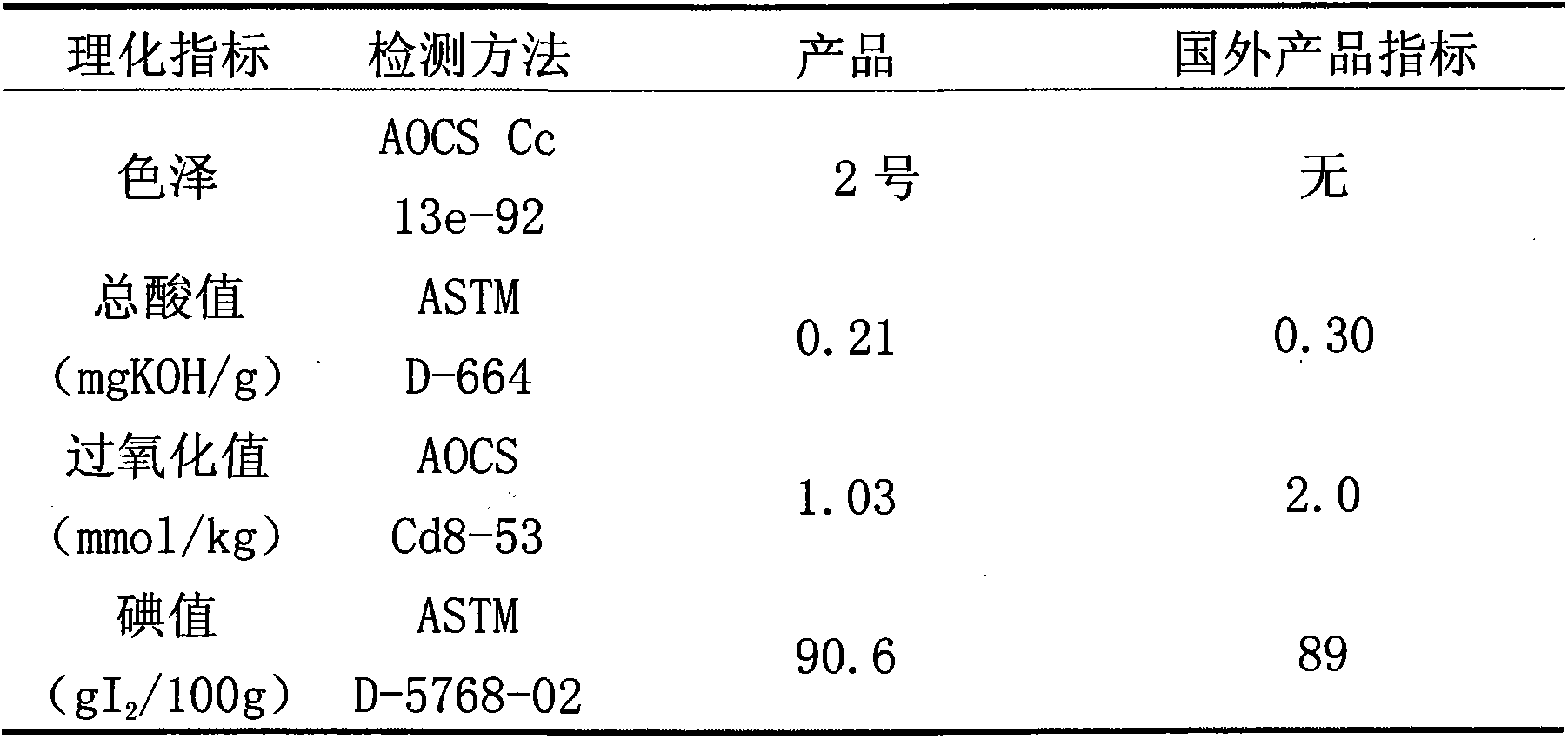

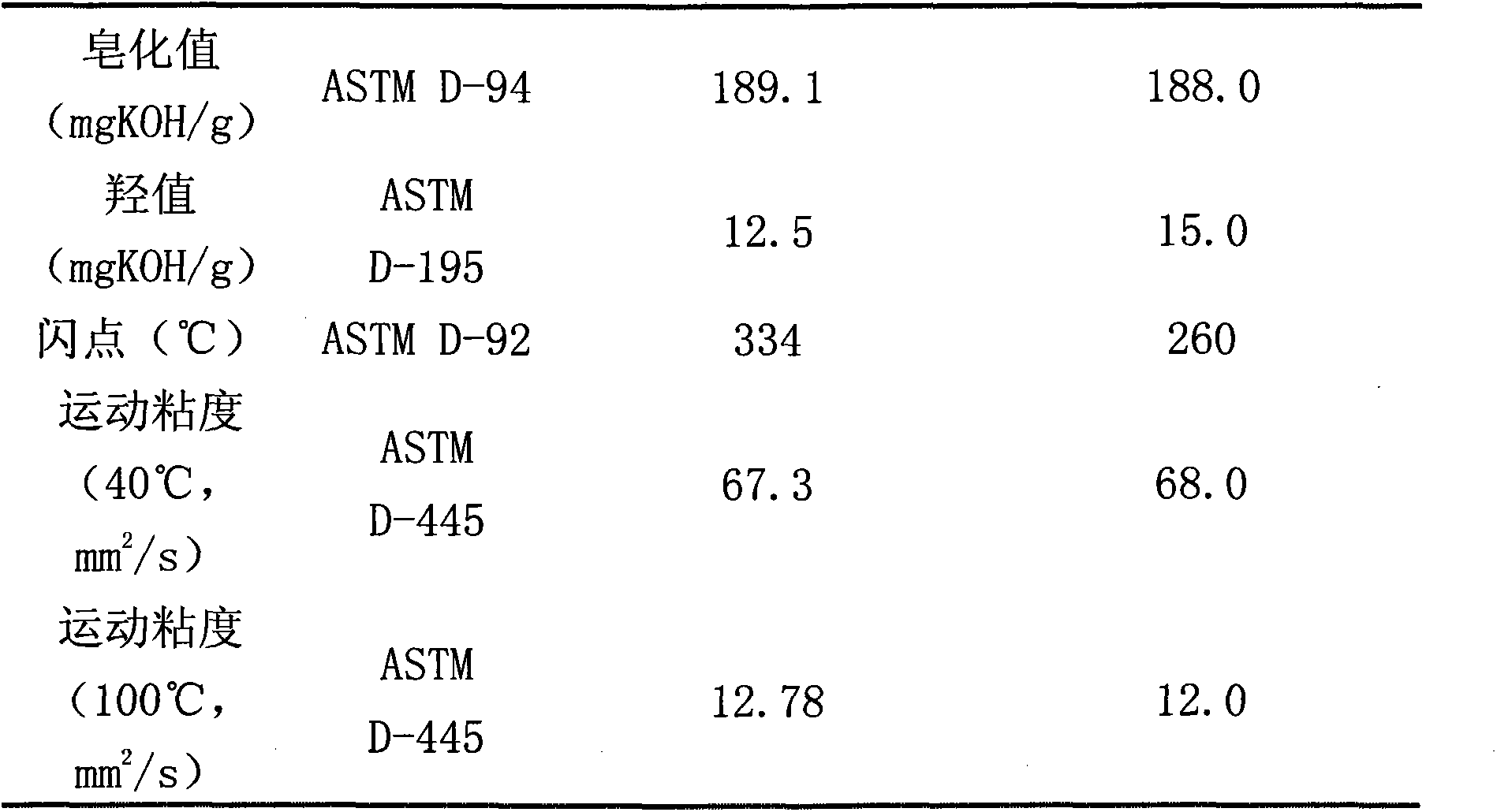

Process for producing pentaerythritol oleate

InactiveCN101245006AEasy to separateNo pollutionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDistillationOleic Acid Triglyceride

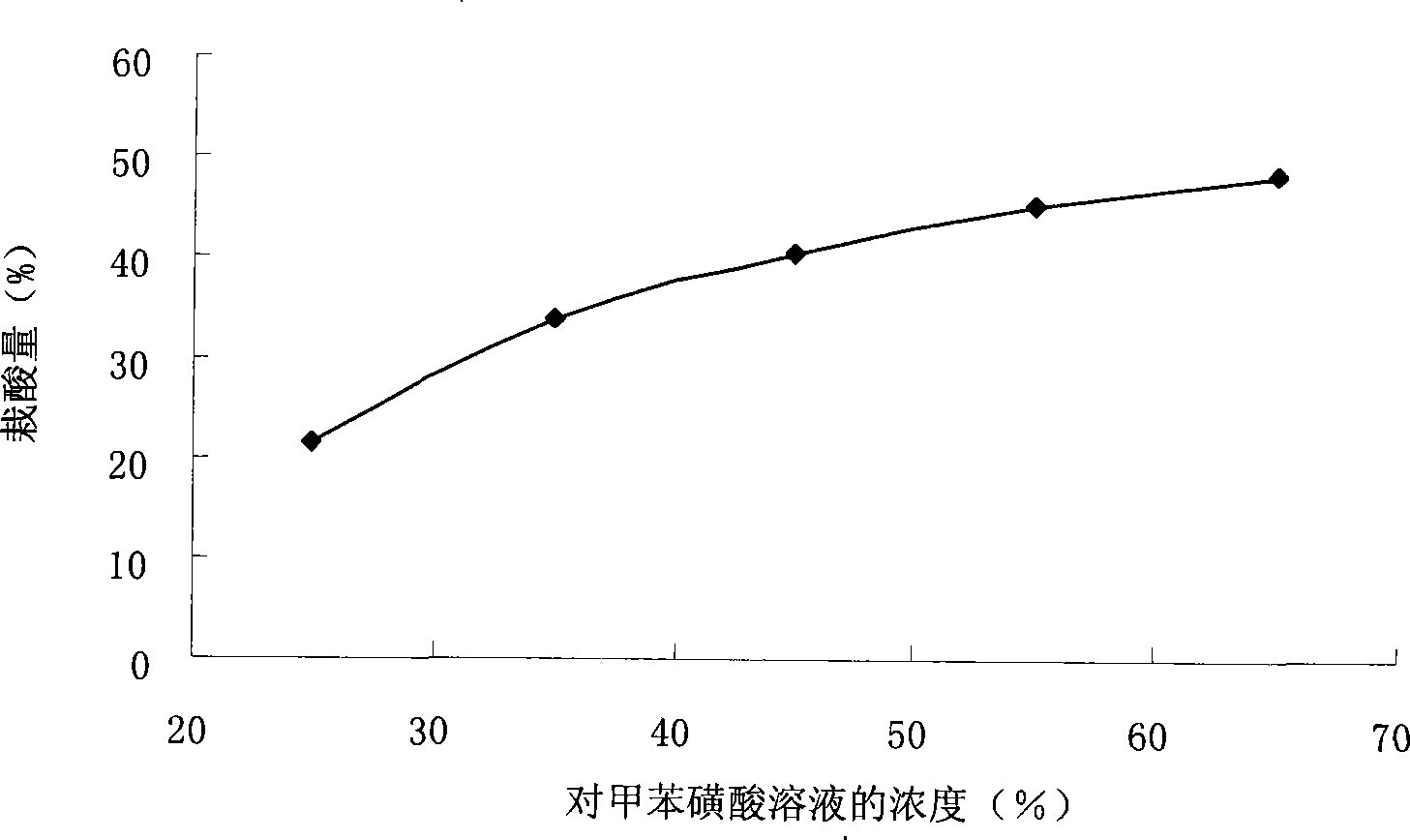

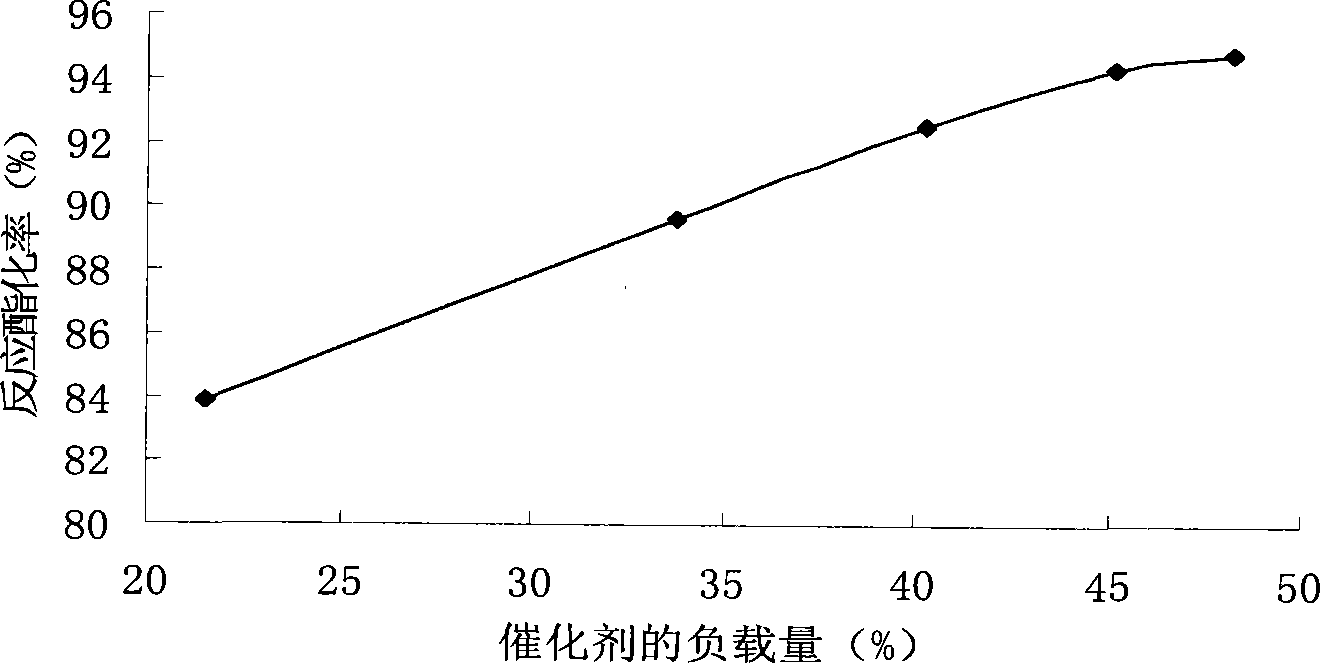

A preparation method of pentaerythrite oleate belongs to the technical field of the synthesis of the foundation oil of biological degradable lubricating oil; the invention provides an improved preparation method of pentaerythrite oleate, which adopts p-toluene sulfonic acid carried by activated carbon as catalyst, oleic acid and pentaerythritol are regarded as raw material for esterification so as to obtain primary products of the pentaerythrite oleate, then molecule distillation treatment is adopted to obtain the products of pentaerythrite oleate; the preparation method of the pentaerythrite oleate chooses economical activated carbon as the load to carry p-toluene sulfonic acid, the activated carbon can be obtained from a plurality of resources, impregnation method is used as the loading method, the method adopts the p-toluene sulfonic acid carried by activated carbon to catalyze reactions for the first time, which has the advantages of obvious catalyzing performance, the catalyst being easy to be separated from products, no acid waste water pollution being caused, and little pollution being caused to environment, and the catalyst is one of environmental-protection catalyst; the pentaerythrite oleate is beneficial for environmental protection, can prolong the service life of machines, and has good safety and renewable capacity.

Owner:JIANGNAN UNIV

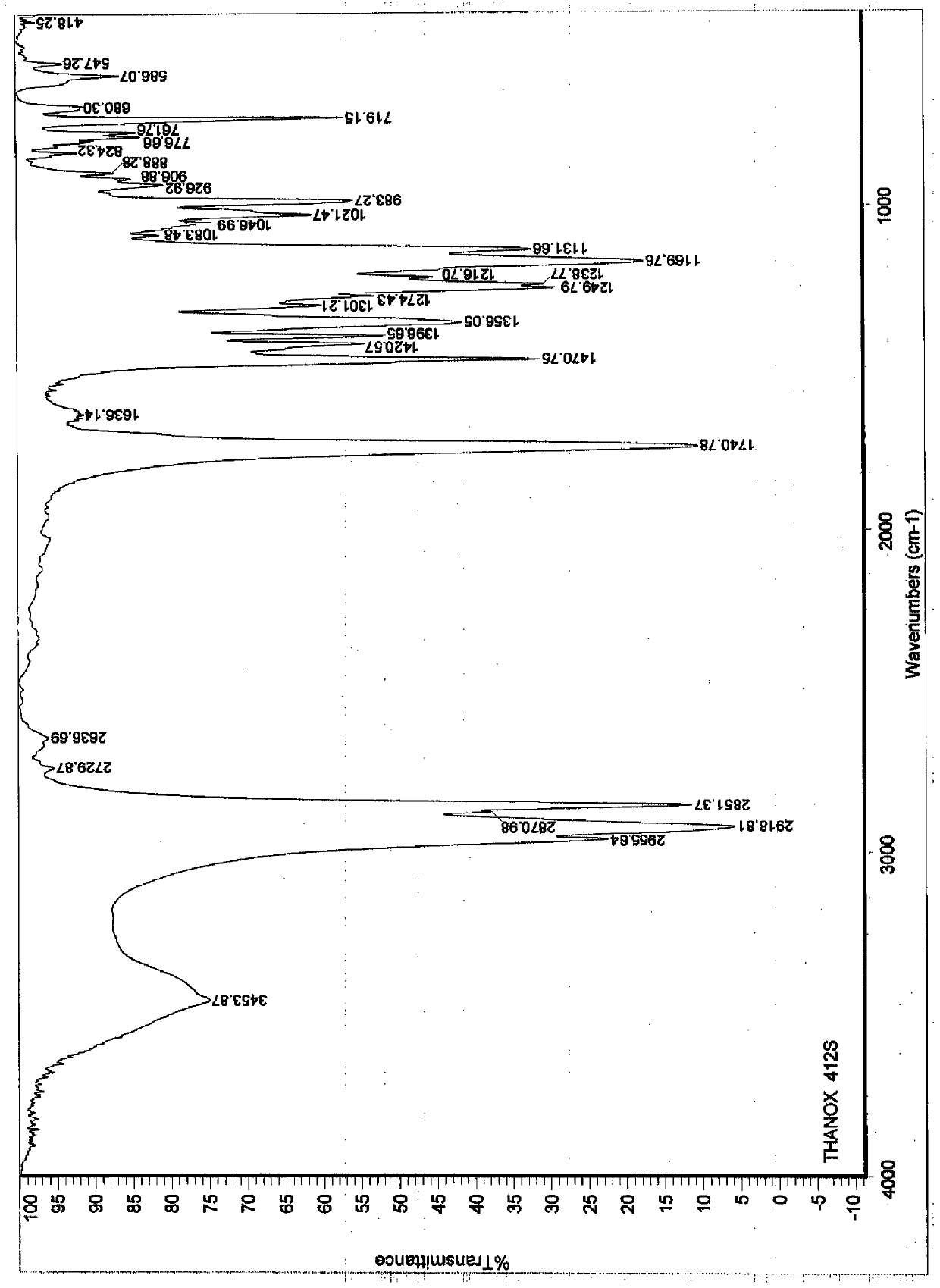

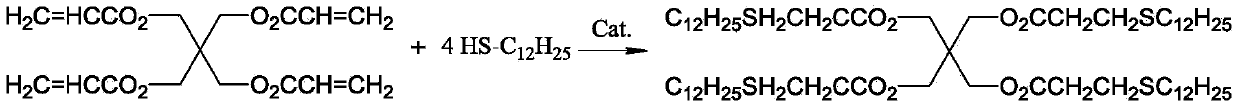

Preparation method of pentaerythritol tetra(3-n-dodecylthiopropionate)

The invention provides a preparation method of pentaerythritol tetra(3-n-dodecylthiopropionate), which initially provides a one-step synthesis method of pentaerythritol tetra(3-n-dodecylthiopropionate) from pentaerythritol tetraacrylate and 1-dodecyl mercaptan. The method comprises the following steps: adding 1-dodecyl mercaptan and a catalyst into a reactor, dropwisely adding pentaerythritol tetraacrylate at 40-60 DEG C to react, distilling out excessive 1-dodecyl mercaptan under reduced pressure, adding formic acid or glacial acetic acid to regulate the pH value to 6-7, adding a crystallization solvent to recrystallize, filtering, and drying to obtain the white crystalline powder product. Compared with the prior art, the novel method provided by the invention has the advantages of simple technique, low equipment and operation cost, energy saving, environmental protection, high product quality and high yield.

Owner:RIANLON

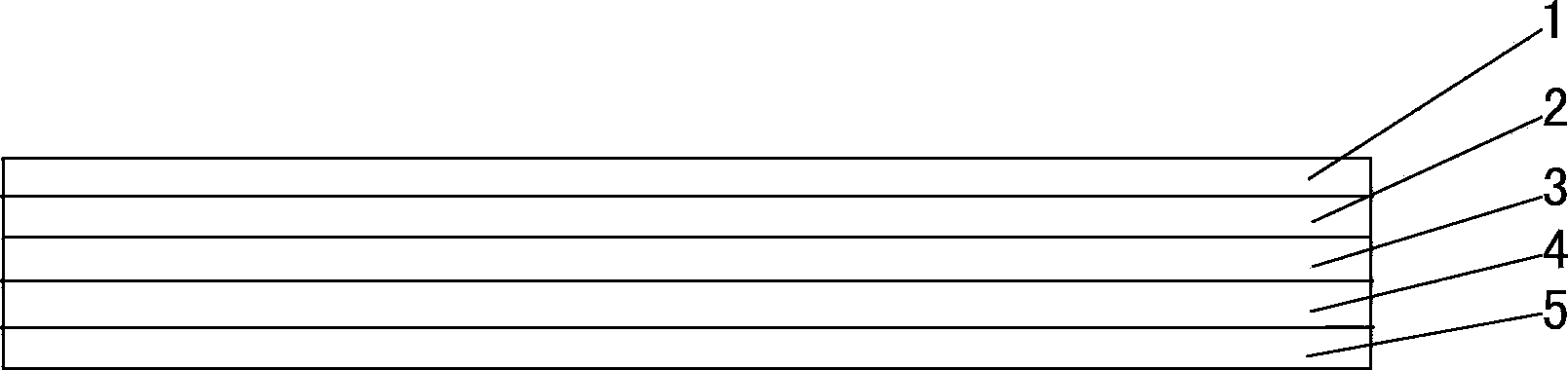

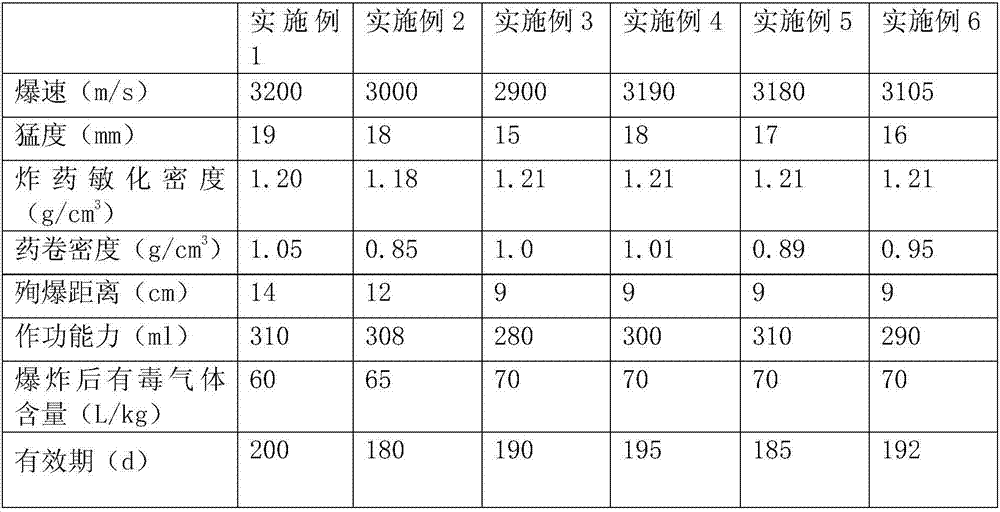

High-barrier-property BOPET (biaxially-oriented polyethylene terephthalate) packaging film and production method thereof

ActiveCN103407257AHigh barrierGood heat sealing performanceFlexible coversWrappersPolyethylene terephthalate glycolBoPET

The high-barrier-property BOPET packaging film is characterized by comprising two PET polyester layers, two PETN (pentaerythritol tetranitrate) polyester layers and an MMT (methylcyclopentadienyl manganese tricarbonyl) modified PET polyester sandwich layer. The high-barrier-property BOPET packaging film is sequentially composed of a PET polyester layer, a PETN polyester layer, an MMT modified PET polyester sandwich layer, a PETN polyester layer and a PET polyester layer from top to bottom. The production method of the high-barrier-property BOPET packaging film is characterized by comprising the following steps: respectively drying PET slices, PETN slices and an MMT modified PET slice by an blast dryer, and extruding through a five-layer coextrusion die head respectively by using three corresponding double screw extruders; carrying out piece casting, longitudinal stretching, lateral stretching, traction rolling and cutting to obtain the high-barrier-property BOPET packaging film. Compared with the prior art, the invention can greatly enhance the barrier property of the packaging film, has the advantages of excellent heat sealability, excellent mechanical properties, high safety, no toxic or harm and low cost, can easily implement industrial production, and can be widely used in the field of packaging of oxygen / water-sensitive foods and drugs.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH

Preparation of pentaerythritol tetraoctyl stearate

ActiveCN101298417AHigh yieldHigh purityOrganic compound preparationCarboxylic acid esters preparationIsostearic acidPentaerythritol

The invention relates to a preparation method of tetraisostearate: the mol ratio of pentaerythritol to isostearic acid is 1: 4.0 to 4.4; the temperature is raised to the range of 160 to 240 DEG C under normal pressure and reacted for 10 to 24 hours by distillation, wherein, the adding amount of a catalyst is 0.1 to 1 percent of the weight of the isostearic acid; after esterification is finished, the temperature is decreased to 50 to 90 DEG C; a nonpolar solvent and a polar solvent are added; the adding amounts of the nonpolar solvent and the polar solvent are respectively 5 to 80 percent and 5 to 80 percent of the weight of the isostearic acid; aqueous slkali is added for alkali washing neutralization; the adding amount is 0.5 to 3 percent of the weight of the isostearic acid; the concentration of the aqueous slkali is 5 to 30 percent; an organic phase is washed to neutral by water; the solvents and water are removed by reduced pressure distillation; then the product is obtained after filtration; each step is carried out under the protection of nitrogen; the preparation method of the invention has high yield; the obtained product has the advantages of light color, low acid value, high purity and being ideally applied to the cosmetic industry.

Owner:广州星业科技股份有限公司

Liquid fuel additive

InactiveCN1730625AThe equipment process is simpleSimple production processLiquid carbonaceous fuelsFuel oilLiquid fuel

The invention discloses a liquid fuel additive comprising puffing agent P 5-10%, pentaerythritol tetranitrate 10-15%, triethanolamine 4-8%, oleinic acid 2-4%, trinitro-methane 1.2-7.2%, propene oxid 0.8-4.8%, ethylene glycol dinitrate 3-13%, diethyleneglycol dinitrate 1-5%, triethylene glycol dinitrate 1-3%, dinitromethane 2-4%, tetranitromethane 1-3%, aluminum dust 2-7%, ammonium nitrate 8-30%, guanidine nitrate 5-15%, potassium permanganate 8-14%, and hydrogen peroxide 2-8%.

Owner:马劳主

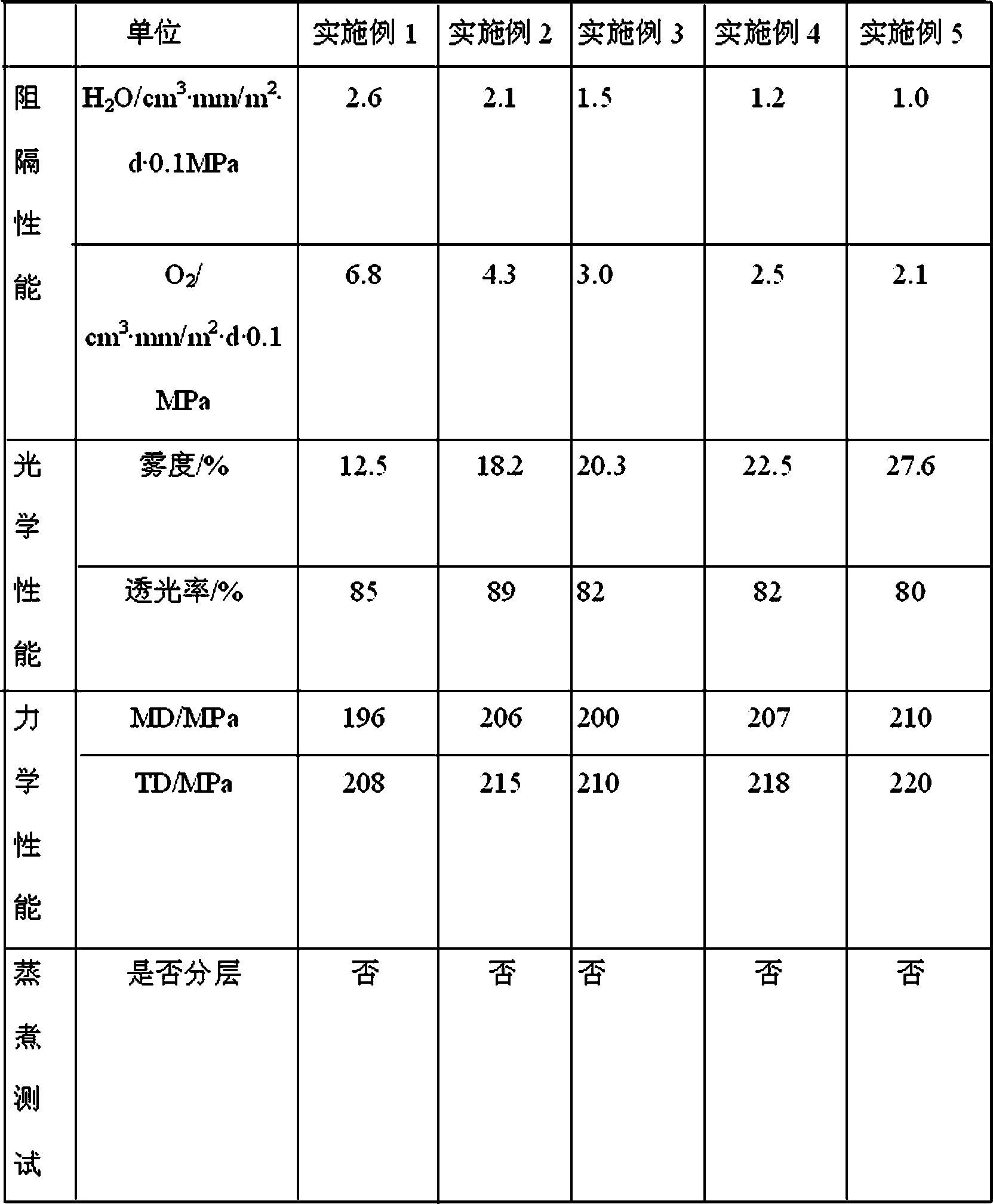

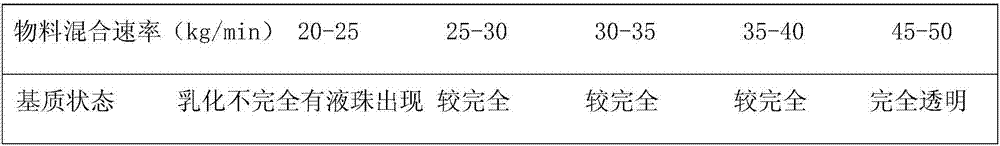

Gelatinous emulsion explosive for drilling shaft and preparation method of gelatinous emulsion explosive

InactiveCN105753617AGood explosion temperatureGood detonation velocityExplosive ingredient compoundingEmulsion explosiveOil phase

The invention relates to gelatinous emulsion explosive for a drilling shaft. The gelatinous emulsion explosive comprises the following components: ammonium nitrate, ammonium sulfate, ammonium chloride, ammonium carbonate, ammonium bicarbonate, ammonium thiosulfate, ammonium thiocyanate, sulfamic acid, ammonium phosphate, ammonium sulfate-nitrate, ammonium phosphate-nitrate, calcium ammonium nitrate, ammonium acetate, ammonium oxalate, ammonium tartrate, ammonium citrate, sodium nitrate, calcium nitrate, urea, dicyandiamide, glycine, methionine, lysine, an ethylene vinyl acetate copolymer, pentaerythritol tetranitrate, trinitrotoluene, nitrogen triiodide, potassium perchlorate, ammonium perchlorate, aluminum powder, titanium powder, iron powder, copper powder, zinc powder, tin powder, mixed rare earth, oil phase, an adhesive additive, a flame inhibitor, a composite gelatinizing agent, an emulsifier, a sensitizing agent, a stabilizing agent, micro hollow spheres and water. Due to addition of raw materials such as the flame inhibitor, the stabilizing agent and the mixed rare earth, the primary explosion sensitivity of the explosive is improved, the detonation resistance and the stability of the explosive are improved, and safe production of mines can be relatively well ensured.

Owner:宜兴市阳生化工有限公司

Antistatic plastic for automotive interior parts

The application relates to antistatic plastic for automotive interior parts. The plastic is prepared from the following raw materials: polypropylene resin, high-density polyethylene resin, POE (Polyolefin Elastomer), polyethylene glycol oleate, sodium allysulfonate, chlorinated paraffin, glass fiber, pentaerythritol stearate, ethylene-glycidyl methacrylate, brucite powder, calcium sulfate, siliconcarbide, carbon nanotube, TiO2 nanoparticle, barium stearate, flame retardant, a composite antioxidant, talcum powder and dispersing agent.

Owner:佛山豆萁科技有限公司

High-stability emulsion explosive for smooth blasting and preparation method of emulsion explosive

InactiveCN107353174AGuaranteed Detonation CapabilityGuaranteed explosive effectNon-explosive/non-thermic compositionsEmulsion explosiveMethylamine nitrate

The invention discloses an emulsion explosive for high-stability smooth surface blasting. The emulsion explosive comprises the following components in parts by mass: solid ammonium nitrate: 30-40 parts, sodium nitrate: 7-9 parts, methylamine nitrate: 10‑13 parts, aluminum powder: 8‑10 parts, water: 7‑11 parts, density regulator: 7‑9 parts, stearic acid: 5‑7 parts, crosslinking agent: 4‑6 parts, foaming paste : 1-3 parts, composite emulsifier: 2-4 parts, sensitizer: 5-7 parts, pentaerythritol tetranitrate: 0.5-1 part; the present invention also designs a kind of emulsified explosive with high stability smooth blasting The preparation method is simple and easy, the preparation cost is low, and the prepared emulsion explosive has good detonation sensitivity and explosive performance, good stability and uniform quality.

Owner:宜兴市阳生化工有限公司

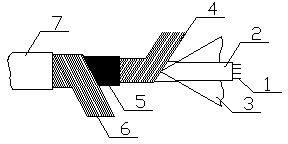

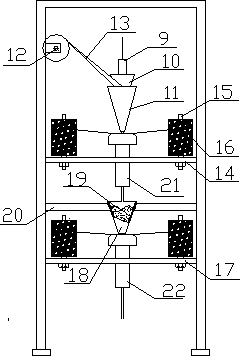

Permissible detonating cord for coal mine, and cord maker thereof

InactiveCN103772079ALower explosion temperatureLow mechanical sensitivityFuse manufactureFuse detonationFiberPentaerythritol tetranitrate

The invention relates to a permissible detonating cord for a coal mine. The core of the detonating cord is mixed type explosive and comprises the following formulas in percentage by weight: 93%-97% of PETN (pentaerythritol tetranitrate) or RDX and 3%-7% of flame inhibitor A; the core is coated with a flame inhibitor B, the formula of the flame inhibitor B is as follows in percentage by weight: 60%-80% of alkaline metal halide, and 20-40% of halogenated hydrocarbon. A cord production machine for producing the detonating cord comprises a rack, a first coil and a second coil are arranged on the rack and are respectively provided with a forming die and a fibrous scaffold, and an explosive feeding device is arranged on the forming die of the second coil. The flame inhibitor is added in the core and the core is coated with the flame inhibitor, so as to omit the asphalt coating, so that the detonating cord is safe and reliable, and the hidden safety hazard of the coal mine can be eliminated; the flame inhibitor feeding device is additionally arranged on the basis of the existing detonating cord production machine, so that the mass production of the detonating cord can be realized.

Owner:云南燃二化工有限公司

Preparation method of pentaerythritol oleate

InactiveCN104230706AQuick responseEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPentaerythritolDistillation

The invention discloses a preparation method of pentaerythritol oleate, which comprises the following steps: preparing a catalyst; sequentially adding oleic acid, pentaerythritol and the catalyst into a reaction kettle to obtain a pentaerythritol oleate primary product, wherein the mole ratio of the oleic acid to the pentaerythritol is (3.95-4.05):1, and the catalyst accounts for 0.75-0.85 wt% of all the materials; and distilling the pentaerythritol oleate primary product at 210 DEG C under the vacuum degree of 9Pa while controlling the acid value at 0.25mg KOH / g, thereby obtaining the pentaerythritol oleate. The oleic acid and pentaerythritol ester are catalyzed by a chemical process in a solvent-free inert gas system to synthesize the pentaerythritol oleate; the product is separated and purified by molecular distillation; and the method has the characteristics of high reaction speed and low product cost, is simple to operate, and has wide application range in industrial production of pentaerythritol oleate at present.

Owner:ANQING ZHONGCHUANG BIOENG

Medicine composition for treating vaginitis as well as gel and preparation method thereof

InactiveCN101757119AIncreased sensitivityConvenient treatmentHydroxy compound active ingredientsEster active ingredientsPremature agingSide effect

The invention relates to the field of traditional Chinese medicines, in particular to a medicine composition for treating vaginitis, which comprises the following components in percentage by weight: 0.1-20.0 percent of blue lotus essential oil, 0.1-20.0 percent of borneol essence, 0.5-5.0 percent of vitamin E, 0.5-15.0 percent of arginine and 0.5-1.0 percent of nitroglycerin or pentaerythritol tetranitrate. The invention also provides a gel of the medicine composition and a preparation method thereof. The medicine composition and the gel thereof can improve the blood circulation around vagina and prevent premature aging of epithelial cells of the vagina, and have no side effect and potential risk on human bodies after long-time use. In the invention, antibiosis experiments show that the medicine composition can inhibit the growth of various pathogenic bacteria, acute skin irritancy tests show that no toxic reaction is found, the microbiological indices of the medicine composition reach the standard, and no pathogenic bacteria exists, thereby the invention has a wide application prospect.

Owner:湖南天龙制药有限公司

Method for producing pentaerythritol stearate by taking swill-cooked dirty oil as raw material

InactiveCN104557535ATake advantage ofSubstantial production costsOrganic compound preparationCarboxylic acid esters preparationPentaerythritolDistillation

The invention discloses a method for producing pentaerythritol stearate by taking swill-cooked dirty oil as a raw material, belonging to the technical field of preparation of chemical products. The method comprises the following steps: preparing to-be-treated swill-cooked dirty oil into a swill-cooked dirty oil pretreatment solution, preparing swill-cooked dirty oil pretreatment liquor, distilling in a distillation tower, transferring the liquor into a fractionating tower for fractionating, thereby obtaining stearic acid; and cooling the stearic acid, adding pentaerythritol and stannous chloride, uniformly stirring, heating and carrying out an esterification reaction. According to the method disclosed by invention, the swill-cooked dirty oil is taken as the raw material, and the traditional stearic acid preparation raw material, namely palm oil is replaced, so that the swill-cooked dirty oil can be fully utilized, and the production cost of the finished pentaerythritol stearate can be greatly reduced.

Owner:吴俊荣

Tire with tread of rubber composition which contains 1,3-bis-(citraconimidomethyhl) benzene or pentaerythritol triacrylate

InactiveUS20020173577A1Reduce heating rateReduce temperature rise rateSpecial tyresTyre tread bands/patternsBenzenePentaerythritol

The invention relates to a tire with a tread of a sulfur cured diene-based rubber composition which contains 1,3-bis-(citraconimidomethyl) benzene or pentaerythritol triacrylate.

Owner:DEEVERS SUSAN LYNN

Method for preparing pentaerythritol triacrylate

ActiveCN103333066ANo pollution in the processHigh yieldOrganic compound preparationCarboxylic acid esters preparationPentaerythritolDistillation

The invention relates to a method for preparing pentaerythritol triacrylate. The method comprises the following steps that pentaerythritol and acrylic acid are added into an esterification reaction container, then, solid acid catalysts are added, polymerization inhibitors are added, the reaction is carried out under the conditions of certain temperature and vacuum degree, then, solid acid catalysts are filtered out, the remained acrylic acid is removed through distillation, and the pentaerythritol triacrylate is obtained. Compared with the prior art, the method has the beneficial effects that volatile organic compounds are not contained, the product yield is high, the products are environment-friendly green products, no pollution is caused on the environment, and the quality of the products is improved.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

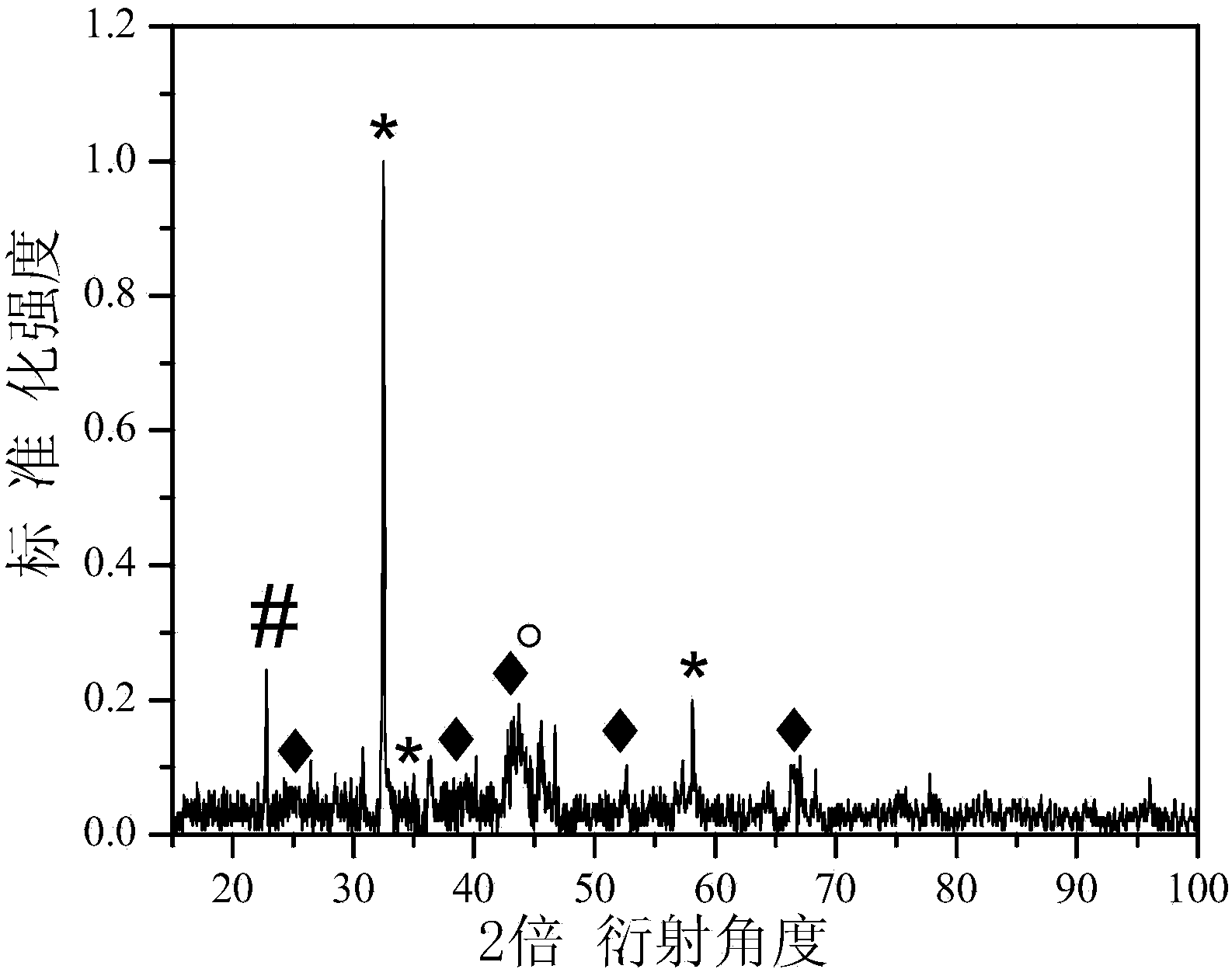

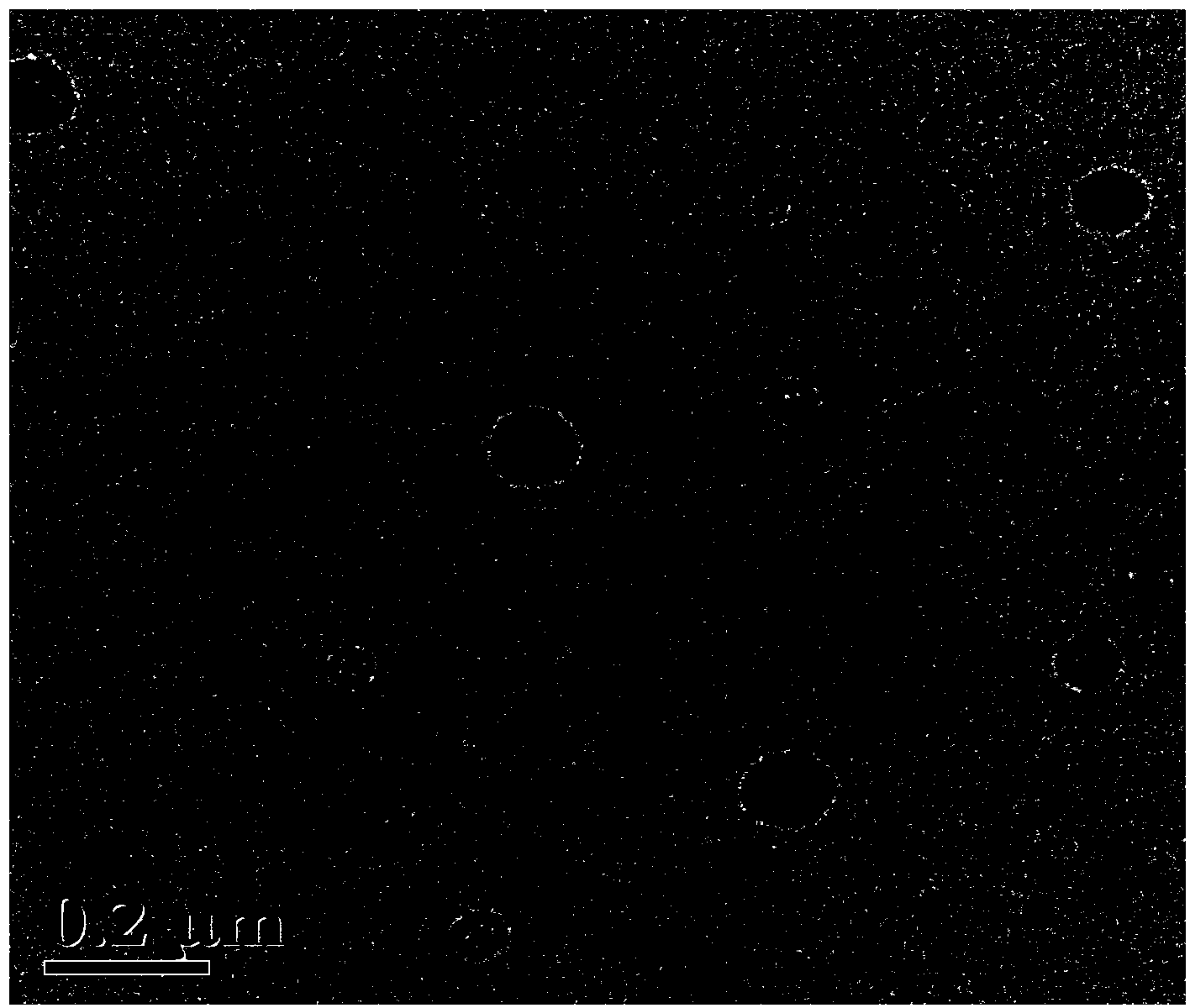

Detonation preparation method for alumina-adhered diamond nano composite particle material

InactiveCN104028171AGood particle dispersionEasy to prepareOther chemical processesUltra-high pressure processesDetonationAluminium hydroxide

The invention discloses a detonation preparation method for an alumina-adhered diamond nano composite particle material, belonging to the technical field of explosion processing. The method is characterized in that the alumina-adhered diamond nano composite particle material is prepared by using a detonation method; when the surfaces of diamond particles are boronized and the diamond particles are mixed with an aluminum salt solution, the particles are subjected to ultrasonic or homogenizing dispersion, the calcination time of the boronized particles is 30 minutes to 1 hour, and the temperature is 400-450 DEG C. Aluminum nitrate, aluminum hydroxide or sodium metaaluminate is adopted as aluminum salt; a negative oxygen balance explosive such as RDX, PETN (pentaerythritol tetranitrate) and an emulsion explosive is properly adopted as a detonation explosive; in an explosion container, water or a series of non-oxidation gas such as carbon dioxide and nitrogen difficultly reacting with oxygen is adopted as a protective medium. The method has the effects and the advantages that the particle dispersion is good; the size of the particles is 50-200nm; the thickness of a coating layer is about 1-2nm; the preparation method is simple and low in cost. The alumina-adhered diamond nano composite particle material is applicable to being directly used as a polishing abrasive material of gem, a silicon wafer and an LED (light emitting diode) substrate, and can be deeply processed into various diamond grinding tools.

Owner:DALIAN UNIV OF TECH

A kind of method utilizing hydrogenated oil to prepare pentaerythritol stearate

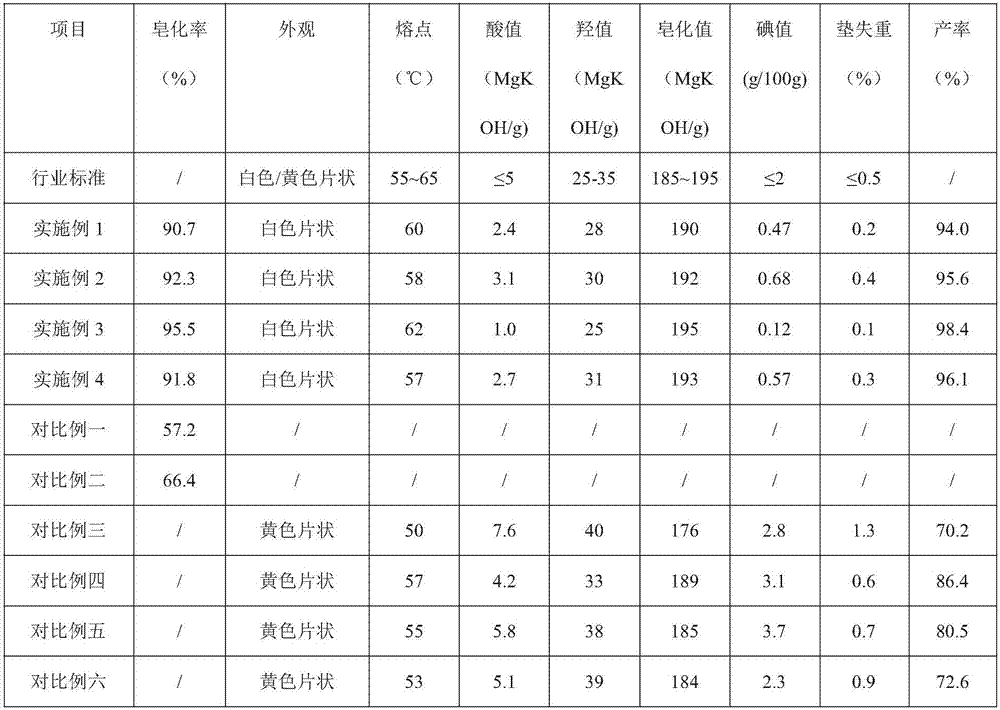

ActiveCN105753698BHigh saponification rateHigh acid valuePreparation from carboxylic acid saltsOrganic compound preparationDistillationStearic acid

The invention discloses a method for preparing pentaerythritol stearate from hydrogenated oil.The method includes the following steps that S1, a sodium hydroxide solution is added to hydrogenated palm oil, microwave processing is conducted, a reaction is conducted under stirring, and saponified matter is obtained; S2, a sulfuric acid solution is added to the saponified matter till the pH value is 1 to 2, the material is transferred into a distillation tower, and stearic acid is obtained after distillation is completed; S3, stearic acid, pentaerythritol and a catalyst are put, the material is heated, negative pressure is controlled, and a reaction is conducted; S4, then the vacuum degree is increased to 0.07-0.09 mpa, the material is heated to 155-165 DEG C, and a reaction is conducted for 130-150 min under heat preservation at constant pressure; S5, cooling is conducted after an esterification condensation reaction is completed, kieselguhr is added for decoloration and deordorization, the material enters a plate-and-frame filter press, filter cakes are removed, filtrate is taken and subjected to powder spraying, bead spraying and slicing, and packaging and storage are conducted.The method is stable, reliable, high in yield and capable of achieving industrial production, and the prepared pentaerythrityl tetrastearate product is good in whiteness, low in acid value and high in purity.

Owner:GUANGZHOU CARDLO BIOCHEM TECH

Enhanced heat-resistant PA66 composite

An enhanced heat-resistant PA66 composite comprises the following raw materials: by mass, 60-80 parts of PA66, 5-8 parts of silicon carbide whiskers, 0.6-0.8 part of pentaerythritol tetrastearate, 0.1-0.2 part of a coupling agent, 0.1-0.3 part of an antioxidant. The coupling agent is N-(beta-aminoethyl)-gamma-aminopropyl trimethoxy silane, gamma-methacryloxy propyl trimethoxy silane or tetraisopropyl di(dioctylphosphate) titanate. The antioxidant is pentaerythritol ester tetra-[beta-(3,5-ditert-butyl-4-hydroxyphenyl )propionate] or tris-(2,4-di-tert-butylphenyl) phosphite. The silicon carbide whiskers are uniformly dispersed in the PA66, so that heat resistance, abrasion resistance and impact resistance strength of the PA66 composite are significantly increased.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

Synthesis process of pentaerythritol tetra(2-ethylhexanoate)

InactiveCN107778177AHigh purityImprove catalytic performancePhysical/chemical process catalystsOrganic compound preparationPentaerythritolPentaerythritol tetranitrate

The invention relates to a method for synthesizing esters, in particular to a method for synthesizing pentaerythritol tetra(2-ethylhexanoate). The synthesis method comprises the following steps: preparation of a solid superacid catalyst; synthesis of the pentaerythritol tetra(2-ethylhexanoate); post-processing of the product. The method has the advantages of being simple in synthesis route of thepentaerythritol tetra(2-ethylhexanoate), mild in conditions and easy in control. The raw material is rich in source and low in cost, so that the production cost is directly lowered. The synthesized pentaerythritol tetra(2-ethylhexanoate) has above 99% of purity and 80% of yield. The synthesis route is suitable for industrial production.

Owner:PANJIN HONGDING CHEM CO LTD

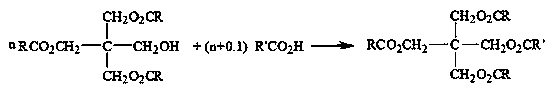

Pentaerythritol tetraester

ActiveUS8772530B2Good compatibilityOrganic compound preparationCarboxylic acid esters preparationPentaerythritolPentaerythritol tetranitrate

Owner:KH NEOCHEM CO LTD

Pentaerythritol tetraester

InactiveUS8664430B2Good compatibilityOrganic compound preparationCarboxylic acid esters preparationPentaerythritolAlcohol

A pentaerythritol tetraester which is a mixed ester of pentaerythritol and carboxylic acids is provided, wherein the carboxylic acids comprise isobutyric acid and 2-ethylhexanoic acid and the molar ratio of isobutyric acid to 2-ethylhexanoic acid in the carboxylic acids is 36 / 64 to 83 / 17. The pentaerythritol tetraester may be used in a refrigerant oil or the like which exhibits excellent miscibility with a difluoromethane refrigerant among other properties.

Owner:KH NEOCHEM CO LTD

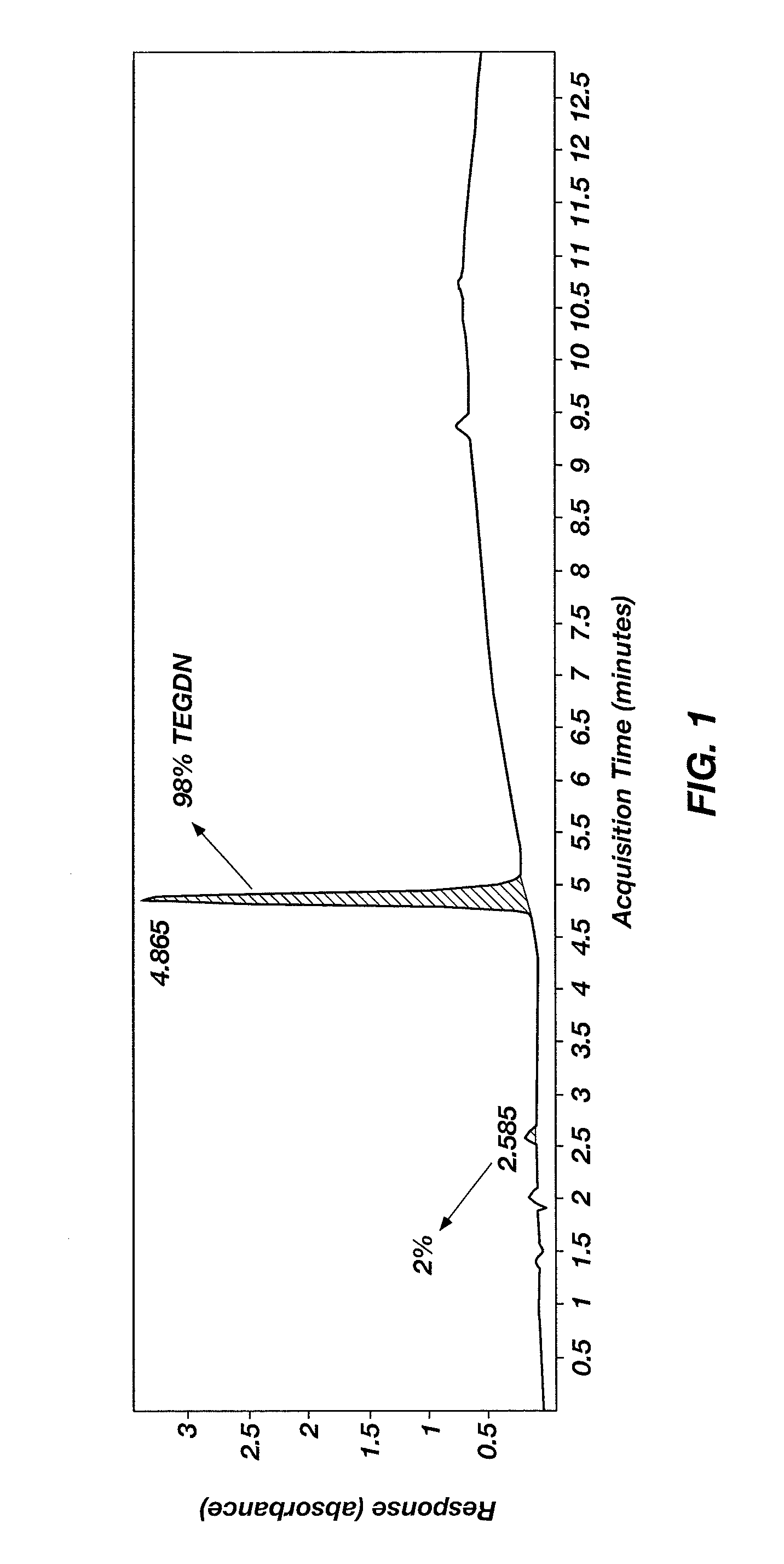

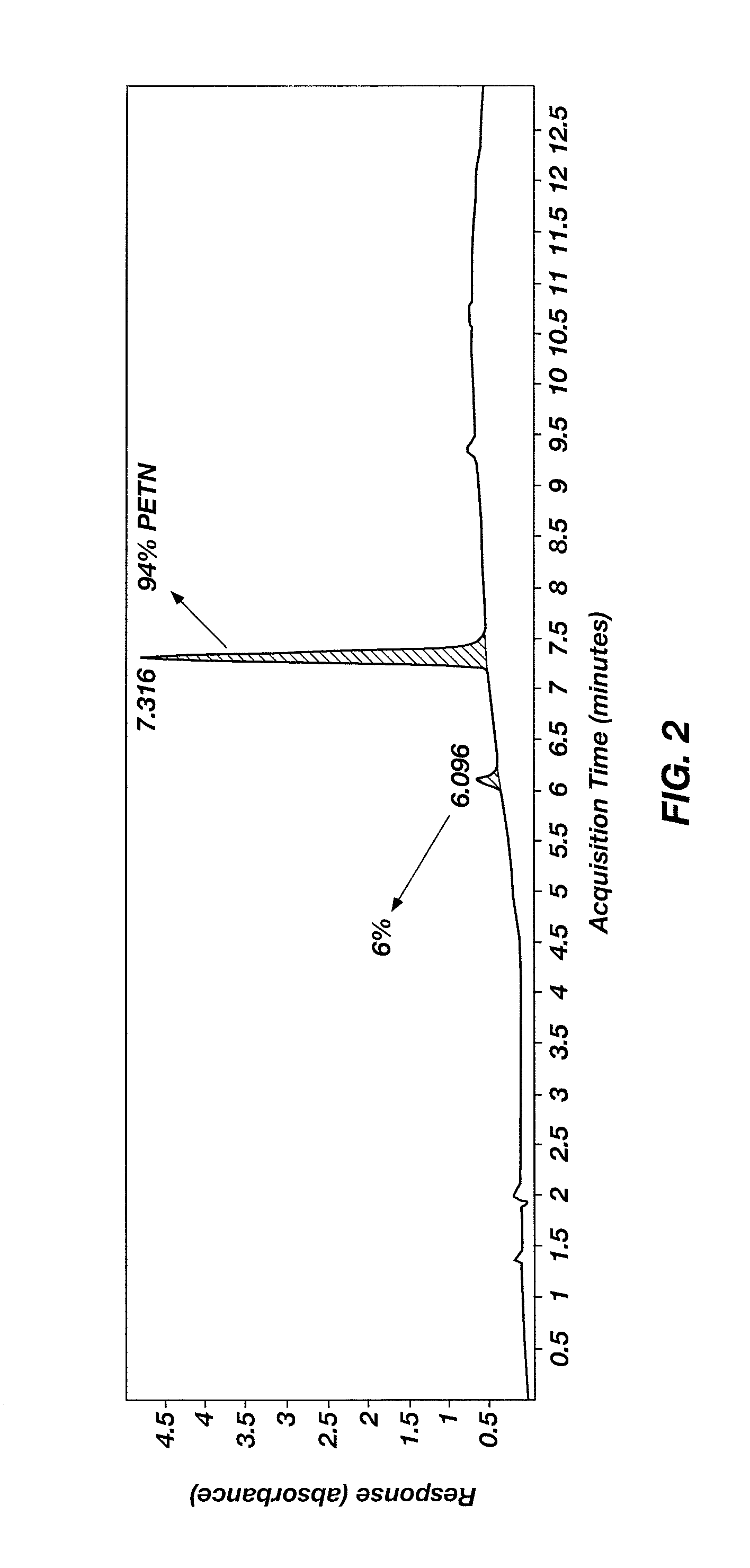

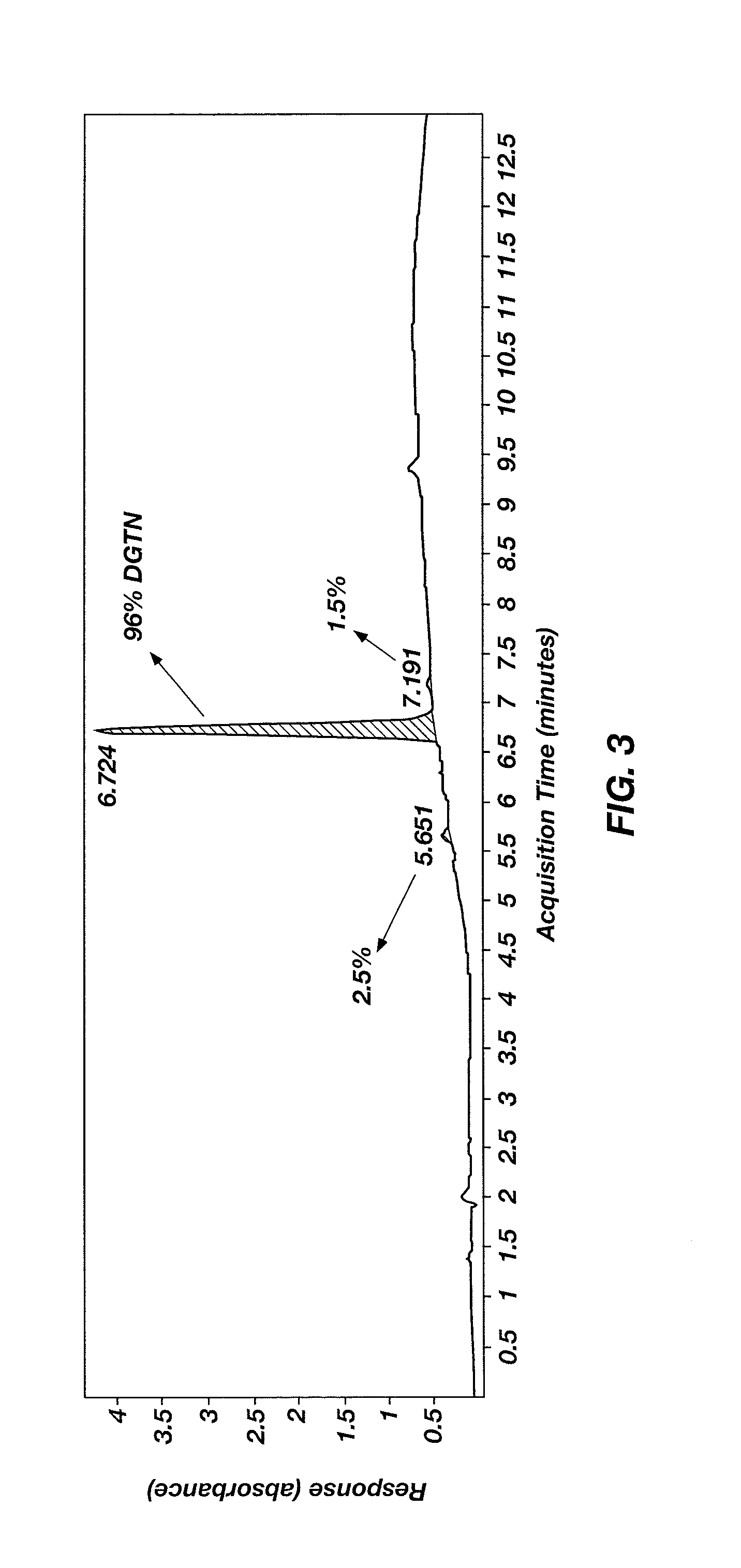

Methods of producing nitrate esters

Methods of forming a nitrate ester include combining at least one nitrate salt and sulfuric acid to form a nitrating solution and adding an aliphatic polyol to the nitrating solution. Nitrate esters formed by this method may be, for example, triethylene glycol dinitrate (TEGDN), pentaerythritol tetranitrate (PETN), diglycerol tetranitrate (DGTN), 1,1,1-tris(methylol)ethane trinitrate (TMETN), 1,2,4-butanetriol trinitrate (BTTN), nitroglycerin (NG), diethylene glycol dinitrate (DEGDN), ethylene glycol dinitrate (EGDN), metriol trinitrate (MTN), nitrocellulose (NC), or 1,2-propanediol dinitrate (PDDN).

Owner:NORTHROP GRUMMAN SYST CORP

Method for preparing high-quality pentaerythritol oleate

InactiveCN108689841AImprove qualityImprove product qualityOrganic compound preparationCarboxylic acid esters preparationPentaerythritolOrganic layer

The invention discloses a method for preparing high-quality pentaerythritol oleate. The method is characterized by comprising the following steps of step 1, adding oleic acid and pentaerythritol according to a molar ratio of oleic acid to pentaerythritol being less than 4, adding a catalyst and a water carrying agent, and reacting; step 2, adding excessive micromolecular weight carboxylic acid, and enabling insufficiently reacted carboxylic acid to completely react, so as to obtain a micromolecular weight carboxylic ester mixture of pentaerythritol tetraoleate and pentaerythritol trioleate; step 3, after the action is completed, cooling to room temperature, washing by water, and removing the water carrying agent at an organic layer under the vacuum condition, so as to obtain the light yellow oily transparent liquid pentaerythritol oleate. Obtained pentaerythritol oleate has the advantages that the quality is high; only about 1.02% to 8.36% of pentaerythritol trioleate acetate is contained, the acid value is smaller than 0.1mgKOH / g, and the quality is better than the quality of the equivalent varieties on market; the price of the raw material is low, the raw material is easy to obtain, the operation is simple and convenient, and the industrialization is easy to realize.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Novel PET (polyethylene terephthalate) strap with multi-layer structure

InactiveCN105882089AImprove wear resistanceImprove folding resistanceSynthetic resin layered productsDomestic articlesPolyesterPolyethylene terephthalate

The invention discloses a novel PET (polyethylene terephthalate) strap with a multi-layer structure. The novel PET strap comprises a PET polyester layer, a PETN (pentaerythritol tetranitrate) polyester layer, a PET modified layer and a PET film sequentially from outside to inside. The novel PET strap has excellent wear resistance, folding resistance, pinhole resistance, tear resistance and the like; the heat shrinkage is quite low and is only 1.25% after the strap is placed at the temperature lower than 120 DEG C for 15 min; the PET strap has good antistatic property. The novel PET strap with the structure has very high toughness, high wear resistance and good antistatic property, can still guarantee work in a complex environment and is particularly suitable for packaging products such as electronic products, high precision instruments and the like.

Owner:铜陵永泰包装材料科技有限公司

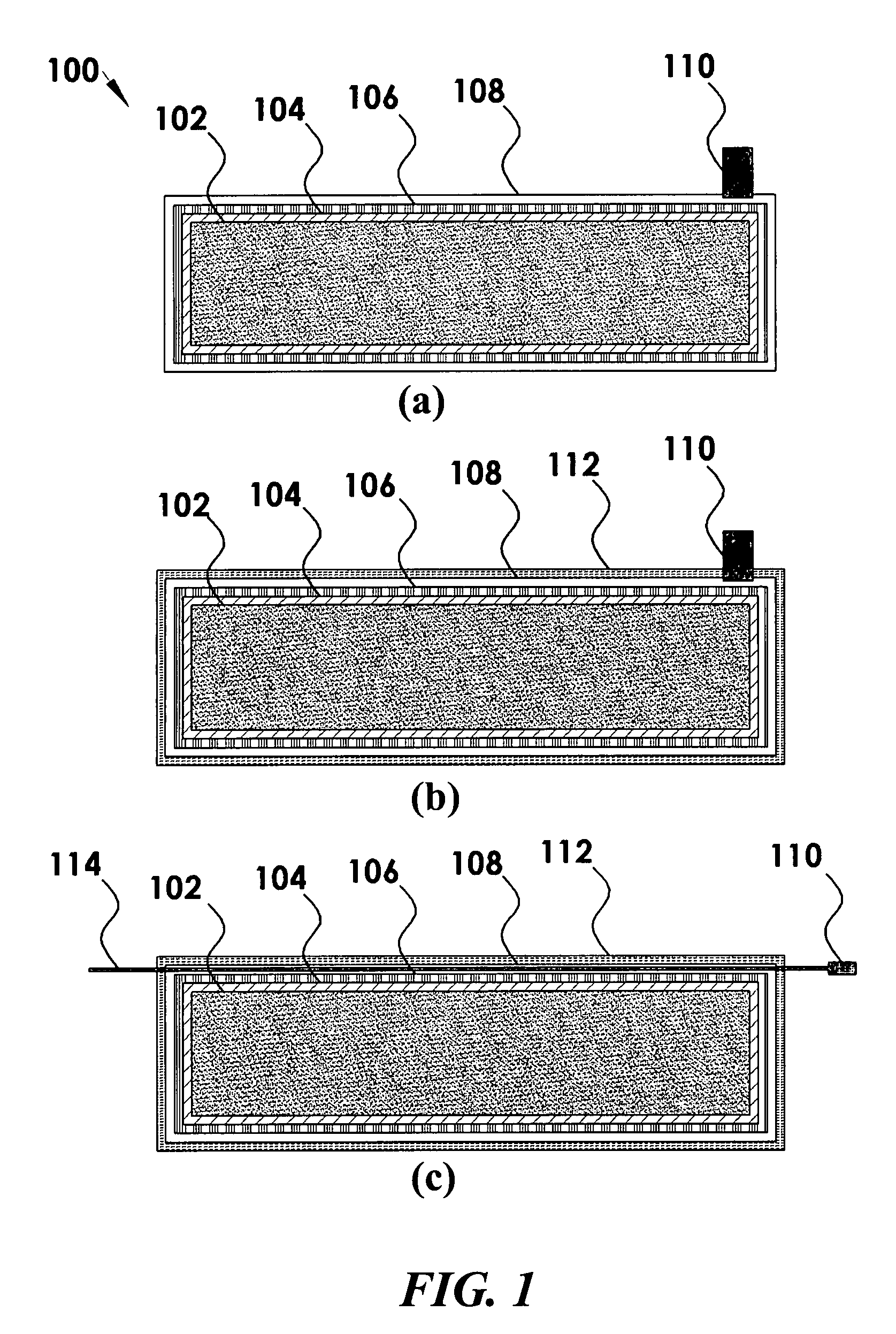

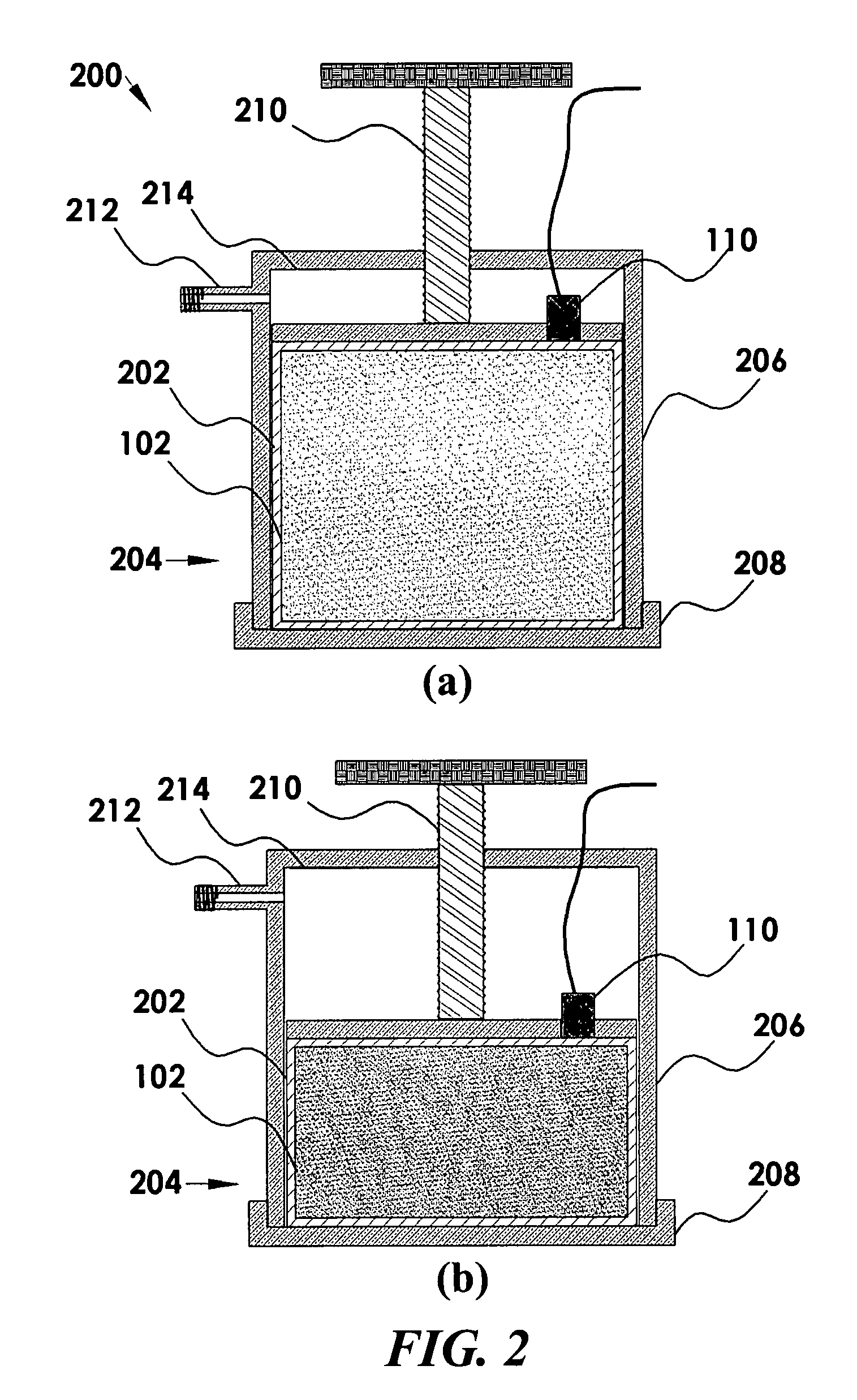

Flexible dilute explosive device

ActiveUS7789982B1Low costShorten the timeNon-explosive fillers/gelling/thickening agentsLoomsVolumetric Mass DensityEngineering

A flexible dilute explosive device is provided that includes an explosive material, such as pentaerythritol tetranitrate (PETN), combined with a non-reactive matrix material, such as light-weight polymer beads, and the combination is held in flexible packaging. The flexible packaging includes fabric, antistatic, evacuated and plastic housings. The flexible dilute explosive device can be applied to any contoured shape in the field. It has a total density that is typically between 5 to 10% greater than its explosive density and can be reliably detonated at lower explosive densities. By using different packaging methods, the flexible dilute explosive device can be made to have a fixed explosive density, or a field tailored explosive density using a variable volume housing. It can have a reduced explosive density by adding inert foam blocks to the combination, having an overall volumetric explosive density reduced to 2.5 lb / ft3 (0.04 g / cm3).

Owner:ACCURATE ENERGETIC SYST LLC

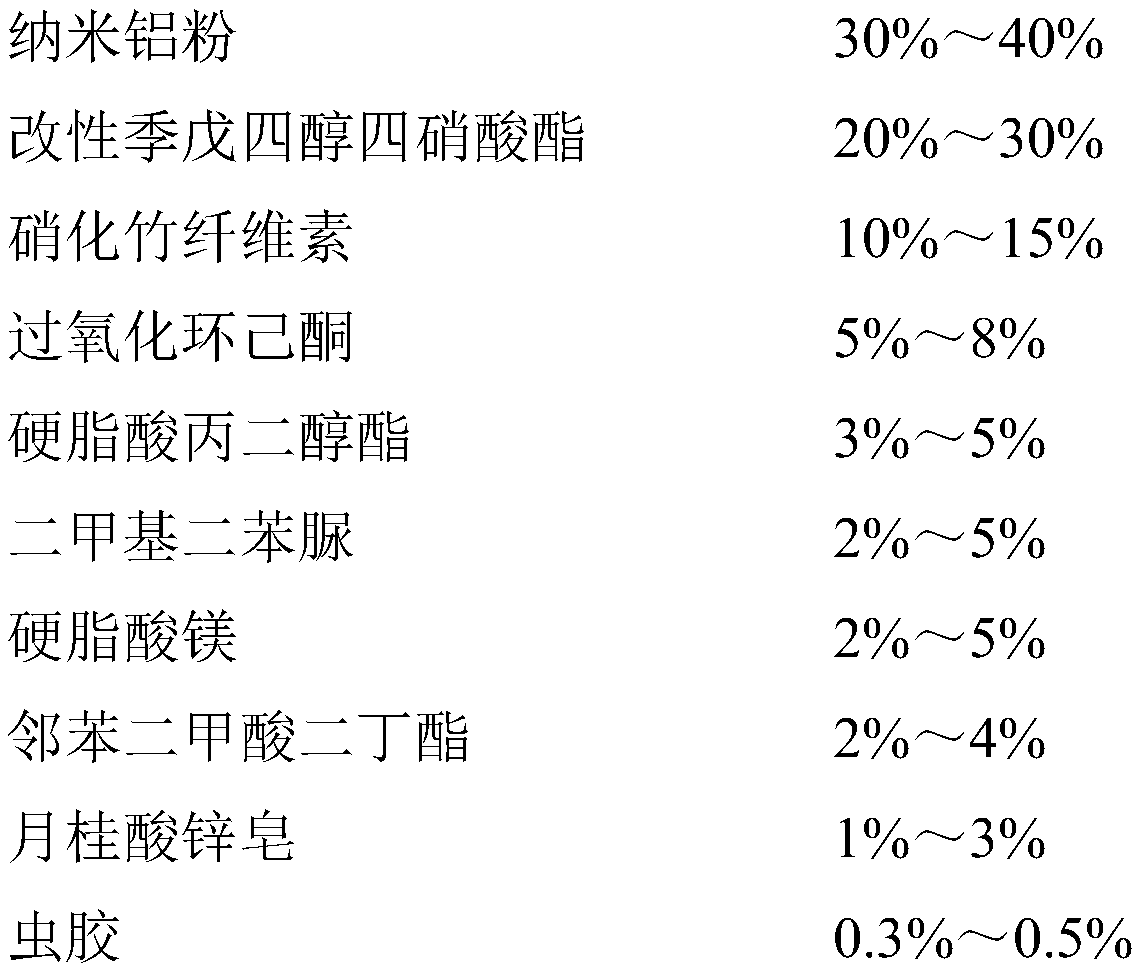

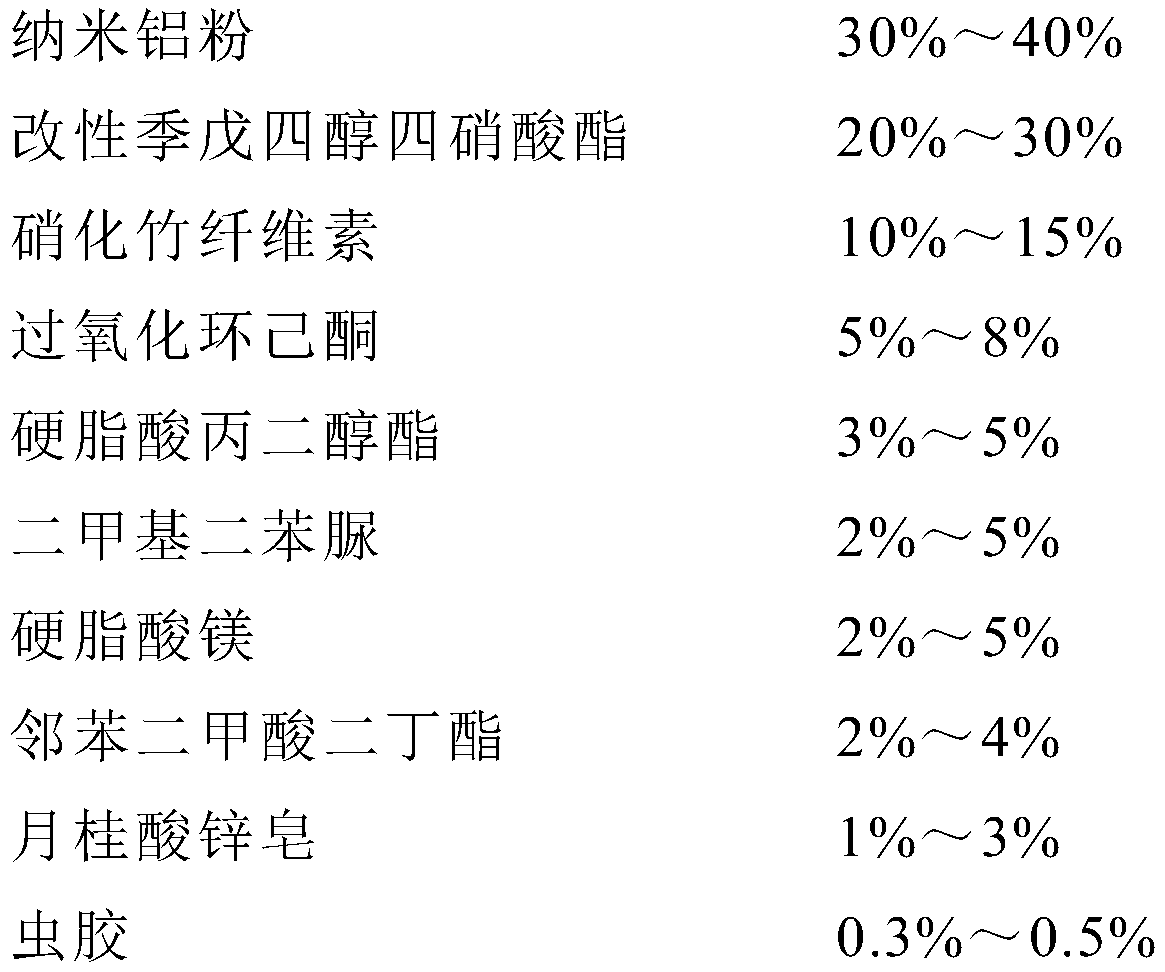

Antistatic treatment of eco-friendly cold firework chemical and preparation method thereof

PendingCN111056886ANothing producedAchieve preparationNitrated pentaerythritol explosive compositionsNon-explosive/non-thermic compositionsCelluloseCyclohexanone

The invention relates to an eco-friendly antistatic smokeless sulfur-free cold firework chemical, and belongs to the field of environment-friendly pyrotechnic compositions. The cold firework chemicalcomprises the components: nano aluminum powder, modified pentaerythritol tetranitrate, nitrobamboo cellulose, cyclohexanone peroxide, propylene glycol stearate, dimethyl diphenyl urea, magnesium stearate, dibutyl phthalate, zinc laurate soap and shellac. The nano aluminum powder and the modified pentaerythritol tetranitrate powder are used as main components, so that safety and reliability are realized, and the combustion temperature is low; the components do not contain chlorine elements and sulfur elements, cyclohexanone peroxide is introduced, sufficient combustion is guaranteed, no toxic or harmful smoke is generated, and preparation of the smokeless and sulfur-free cold firework chemical can be truly achieved.

Owner:江西吉润花炮新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com