Permissible detonating cord for coal mine, and cord maker thereof

A detonating cord and coal mine technology, applied in the direction of detonating cord, fuse manufacturing, etc., can solve the problems of gas explosion, low flame-extinguishing dose, hidden dangers of coal mine safety production, etc., and achieve the effect of reducing mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

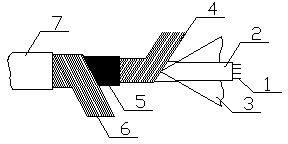

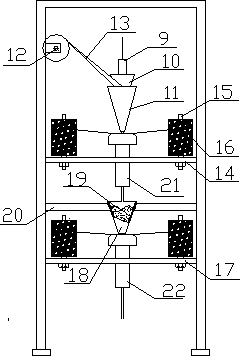

[0014] A detonating cord permitted for coal mines, comprising a drug core 2 and a core wire 1, the number of the core wires 1 is four, the drug core 2 is a mixed explosive, and the formula weight ratio of the drug core 2 is: PETN Or RDX is 93%-97%, chlorinated paraffin 70 is 3%-7%, the particle size of the drug core 2 is 22 mesh to 60 mesh, and the charge amount of the drug core 2 is 11g / m~13 g / m; the drug core 2 is covered with a polypropylene film 3, the polypropylene film 3 is 15mm-22mm wide and 0.05-0.10mm thick; the polypropylene film 3 is covered with an inner chemical fiber 4. There is a flame suppressant layer 5 outside the inner chemical fiber 4, and the flame suppressant layer 5 is formed by concentrically wrapping the drug core with the flame suppressant B, and the formula weight ratio of the flame suppressant B is: alkali metal 60% to 80% of halides, 20% to 40% of halogenated hydrocarbons, particle size of 22 mesh to 60 mesh; then wrap and fix the flame suppressa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com