Novel neon gas protection explosive welding method and explosive welding structure

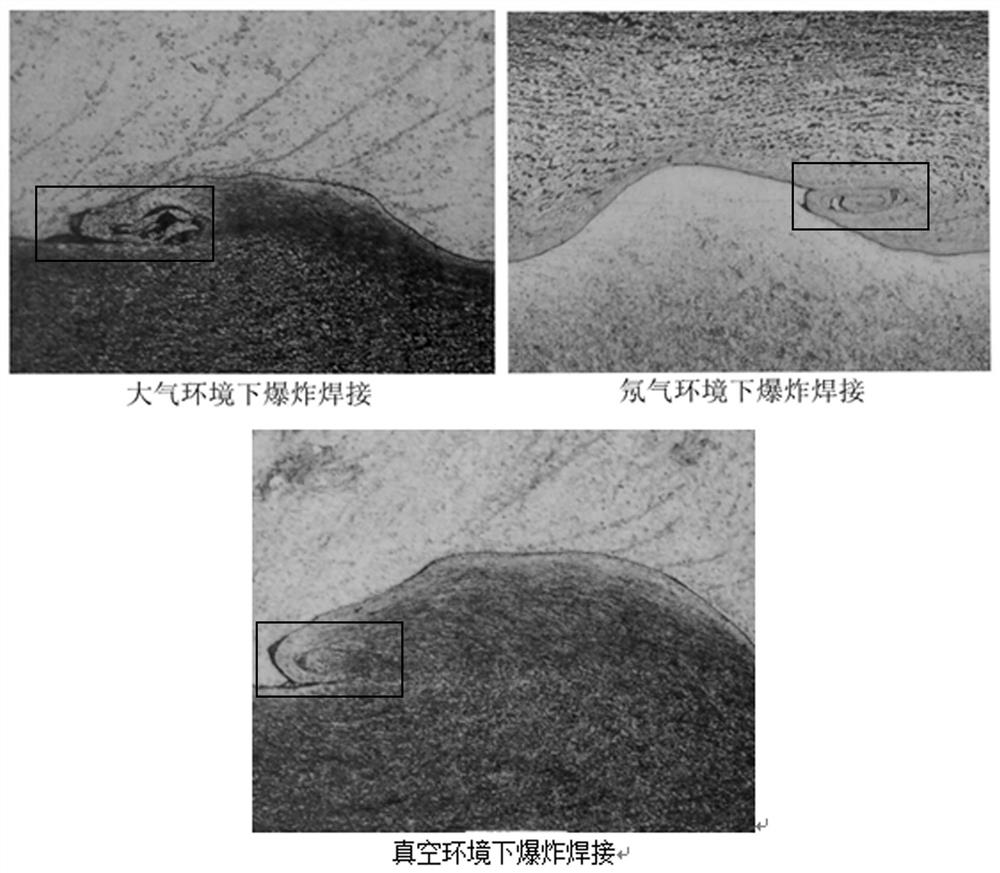

An explosive welding and neon gas technology, which is applied in the field of neon gas-protected new explosive welding method and explosive welding structure, can solve the problems of delamination fracture and cracking of welded workpieces, so as to avoid interface melting, reduce the risk of cracking, and improve The effect of weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: a kind of neon gas protection novel explosive welding method comprises the steps:

[0039] S1 Cleaning: Clean the surface of the substrate and the double board to be bonded respectively;

[0040] S2 Assembly: Assemble the base plate and double plate cleaned in step S1 according to the principle of “the base plate is on the bottom, the double plate is on the top, and the surface to be welded is opposite”, and a gap support is placed between the base plate and the double plate. The base plate is carbon steel, Stainless steel or nickel-based alloy; double plate is one or more of titanium, zirconium, tantalum, niobium, aluminum, magnesium;

[0041] S3 dispensing medicine and detonator: arrange medicine and detonator on the upper surface of the doubler board;

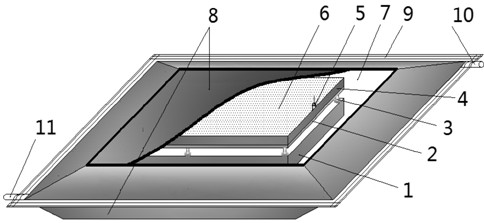

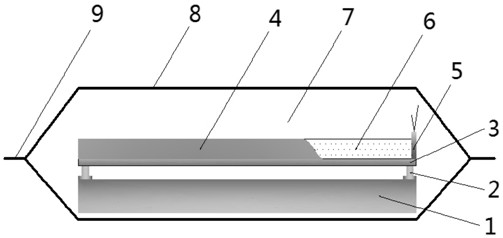

[0042] Preparation of S4 welded closed space: Use aluminum-plastic hot-melt film to seal the assembled substrate and double board of S3 to form a closed space, and reserve air extraction / inflation ports...

Embodiment 2

[0051] Embodiment 2: a kind of neon gas protection novel explosive welding method, comprises the steps:

[0052] S1 Cleaning: Clean the surface of the substrate and the double board to be bonded respectively;

[0053] S2 Assembly: Assemble the base plate and double plate cleaned in step S1 according to the principle of “the base plate is on the bottom, the double plate is on the top, and the surface to be welded is opposite”, and a gap support is placed between the base plate and the double plate, wherein the base plate is carbon steel; Double plate is titanium, zirconium alloy;

[0054] S3 dispensing medicine and detonator: arrange medicine and detonator on the upper surface of the doubler board;

[0055] Preparation of S4 welded closed space: Use aluminum-plastic hot-melt film to seal the assembled substrate and double board of S3 to form a closed space, and reserve air extraction / inflation ports, gas composition / pressure detection at diagonal positions Mouth; Aluminum-pla...

Embodiment 3

[0064] Embodiment 3: a kind of neon gas protection novel explosive welding method comprises the following steps:

[0065] (1) Before performing explosive welding, it is necessary to clean up the oxide skin on the surface of the base plate and the double plate to be combined. Usually, the surface of ordinary steel plate is polished with 80-mesh impeller; the surface of titanium, zirconium, tantalum, and niobium is polished with 40-mesh impeller. , to prevent metal surface oxidation; aluminum and magnesium plates are treated with stainless steel wire wheels. During the polishing process, the compression strength is not higher than 0.4MPa to prevent metal surface oxidation and severe scratches on the surface.

[0066] (2) Preparation of closed space for explosive welding: the closed space is composed of aluminum-plastic hot-melt film, which is divided into upper and lower pieces; after leveling the site for explosive welding, lay the lower aluminum-plastic hot-melt film on the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com