Medium-low detonation velocity liquid explosive and preparation process thereof

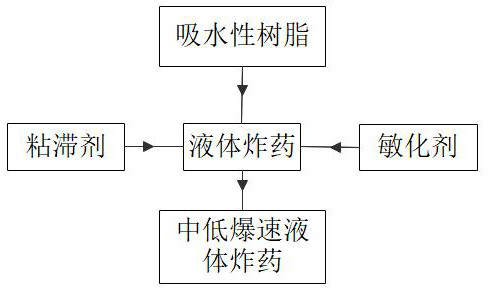

A liquid explosive and low detonation velocity technology, which is applied in the direction of explosive processing equipment, explosives, explosive composite components, etc., can solve the problems of low detonation and detonation sensitivity, uneven distribution of the system, poor fluidity, etc., and achieve uniform energy density, The effect of reducing the cost of use and uniform distribution of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

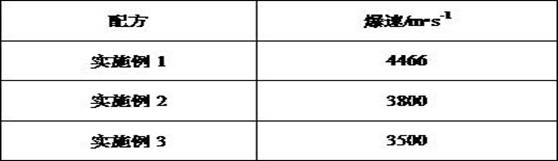

[0028] Add 4.5g of cellulose acetate to 72g of nitromethane, let it stand, and stir evenly after it is completely dissolved, add 20.00g of water-absorbent resin after absorbing water and swell, stir evenly, add 3.50g of glass microspheres, and stir evenly. The measured detonation velocity is shown in Table 1.

Embodiment 2

[0030] Add 4g of cellulose acetate to 62.5g of nitromethane, let it stand still, and stir evenly after it is completely dissolved, add 30.00g of water-absorbent resin after absorbing water and swell, stir evenly, add 3.50g of glass microspheres, and stir evenly. The measured detonation velocity is shown in Table 1.

Embodiment 3

[0032] Add 3.5g of cellulose acetate to 53g of nitromethane, let it stand still, stir evenly after it is completely dissolved, add 40.00g of water-absorbent resin after absorbing water and swell, stir evenly, add 3.50g of glass microspheres, and stir evenly. The measured detonation velocity is shown in Table 1.

[0033] Table 1 The detonation velocity of various formula liquid explosives

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com