High-barrier-property BOPET (biaxially-oriented polyethylene terephthalate) packaging film and production method thereof

A packaging film and high-barrier technology, applied in the high-barrier BOPET packaging film and its production field, can solve the problems of low barrier properties of ordinary PET packaging films, achieve excellent heat-sealing performance and mechanical properties, easy to industrialize production, improve The effect of barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

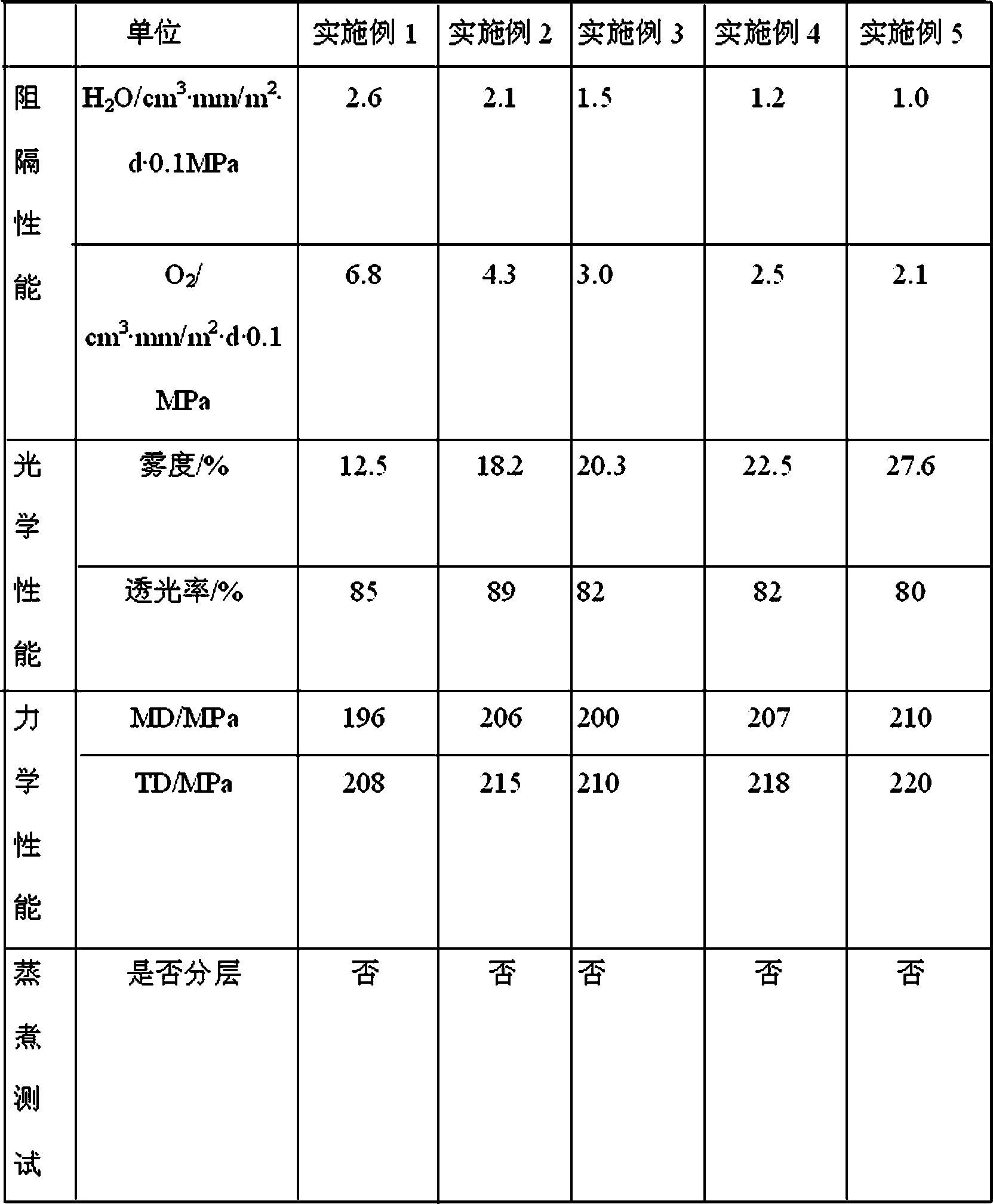

Examples

Embodiment 1

[0018] PET slices, PETN slices, and MMT modified PET slices are dried by a blower dryer, respectively, and then extruded by three corresponding twin-screw extruders through a five-layer co-extrusion die, and then sequentially passed through casting, Longitudinal stretching, transverse stretching, traction winding, slitting to produce high barrier BOPET packaging film.

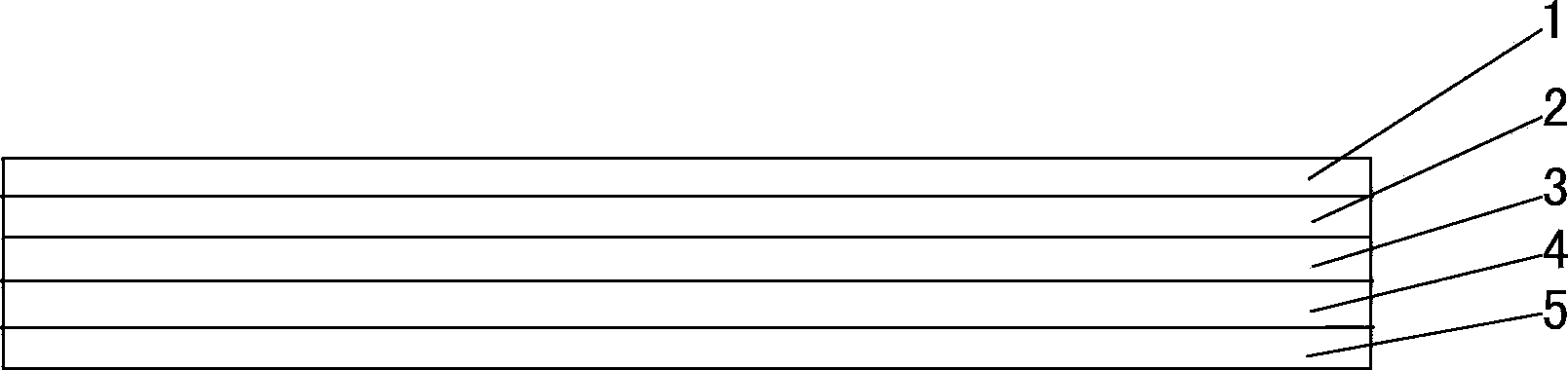

[0019] Such as figure 1 As shown, the high-barrier BOPET packaging film made above includes two layers of PET polyester layers, two layers of PETN polyester layers, one layer of MMT modified PET polyester core layer, and the first PET polyester layer from top to bottom. Ester layer 1, first PETN polyester layer 2, MMT modified PET polyester core layer 3, second PETN polyester layer 4, second PET polyester layer 5.

[0020] The PET chips are selected from PET chips with a melting point of 200° C. and a viscosity of 0.65 dl / g (Sinopec Shanghai Petrochemical Co., Ltd.).

Embodiment 2

[0025] The difference between this example and Example 1 is that: the PET chips with a melting point of 180° C. and a viscosity of 0.65 dl / g (Sinopec Shanghai Petrochemical Co., Ltd.) are selected.

[0026] The PETN chips are made of PEN chips with a mass content of 20% (Dongguan Qiyuan Plastic Raw Material Co., Ltd.), PET chips with a mass content of 80% and a melting point of 180°C and a viscosity of 0.65dl / g (Sinopec Shanghai Petroleum Co., Ltd. Chemical Co., Ltd.).

[0027] The mass content of MMT (Zhejiang Fenghong Clay Chemical Co., Ltd. DK0) in the MMT blend-modified PET chips is 0.3%, and the mass percentage content of PET is 99.7%.

[0028] The drying temperature of the PET chips is 120°C, the drying temperature of the PETN chips is 150°C, the drying temperature of the MMT blended modified PET chips is 140°C, and the drying time is 4 hours. The temperature of the extruder 1 is 260°C, and the temperature of the extruder 2 The temperature of extruder 3 is 275°C...

Embodiment 3

[0030] The difference between this example and Example 1 is that the PET chips (Sinopec Shanghai Petrochemical Co., Ltd.) with a melting point of 210° C. and a viscosity of 0.70 dl / g are selected for the PET chips.

[0031] The PETN chips are made of PEN chips with a mass content of 20% (Dongguan Qiyuan Plastic Raw Material Co., Ltd.), PET chips with a mass content of 80% and a melting point of 210°C and a viscosity of 0.70dl / g (Sinopec Shanghai Petroleum Co., Ltd. Chemical Co., Ltd.).

[0032] The mass content of MMT (Zhejiang Fenghong Clay Chemical Co., Ltd. DK0) in the MMT blended modified PET polyester layer is 1%, and the mass percentage content of PET is 99%.

[0033] The drying temperature of the PET chips is 120°C, the drying temperature of the PETN chips is 130°C, the drying temperature of the MMT blended modified PET chips is 130°C, and the drying time is 4 hours. The temperature of the extruder 1 is 240°C, and the temperature of the extruder 2 The temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com