Antistatic treatment of eco-friendly cold firework chemical and preparation method thereof

A friendly, antistatic technology, applied in the direction of non-explosive/non-thermal agent components, explosives, offensive equipment, etc., can solve the problems of smoke pollution, static electricity, accumulation, etc., to achieve improved antistatic performance, low combustion temperature, and fewer steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

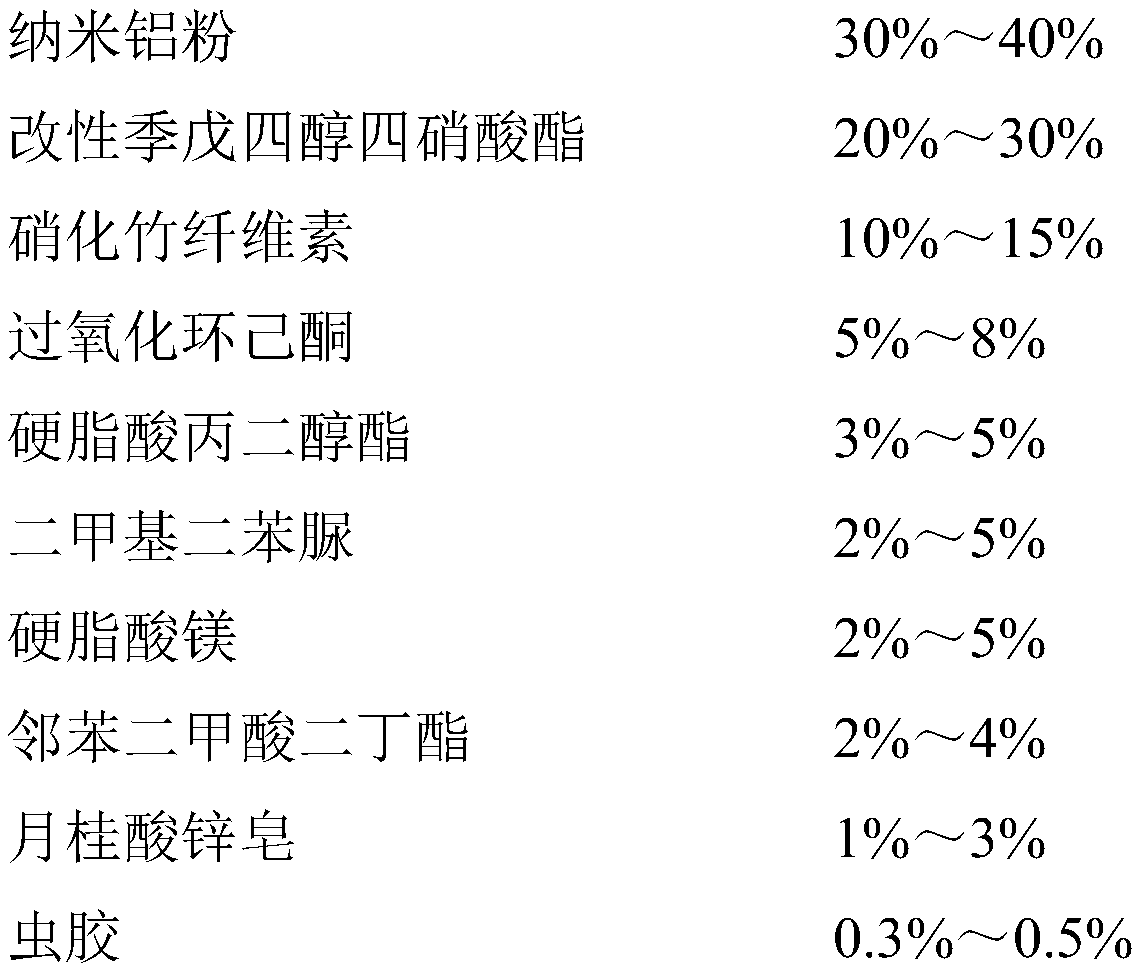

[0027] An eco-friendly antistatic smokeless and sulfur-free cold smoke flower agent, the mass percentage of each component is as follows:

[0028]

[0029] Take 31.23g of nitrobamboo cellulose powder and divide it into two groups of A and B, wherein 8.23g of group A and 23g of group B, and dissolve the nitrobamboo cellulose powder of group A in 82.3g of ethyl acetate, and stir under ultrasonic dispersion conditions 2.5 hours, then continue under stirring state, add 2.73g zinc laurate soap powder and 7.39g magnesium stearate powder, stir, make nitrocellulose mixed sol;

[0030] Add 50g of pentaerythritol tetranitrate powder and 3.5g of titanate coupling agent to 500g of acetone and disperse ultrasonically for 40 minutes to obtain mixed solution C; transfer mixed solution C to an ice-water bath for stirring; then add 1.2g of polyethylene Add the alcohol butyral adhesive to the mixed solution C and stir for 3.5 hours; transfer the reaction device to an oil bath at 80°C and let...

Embodiment 2

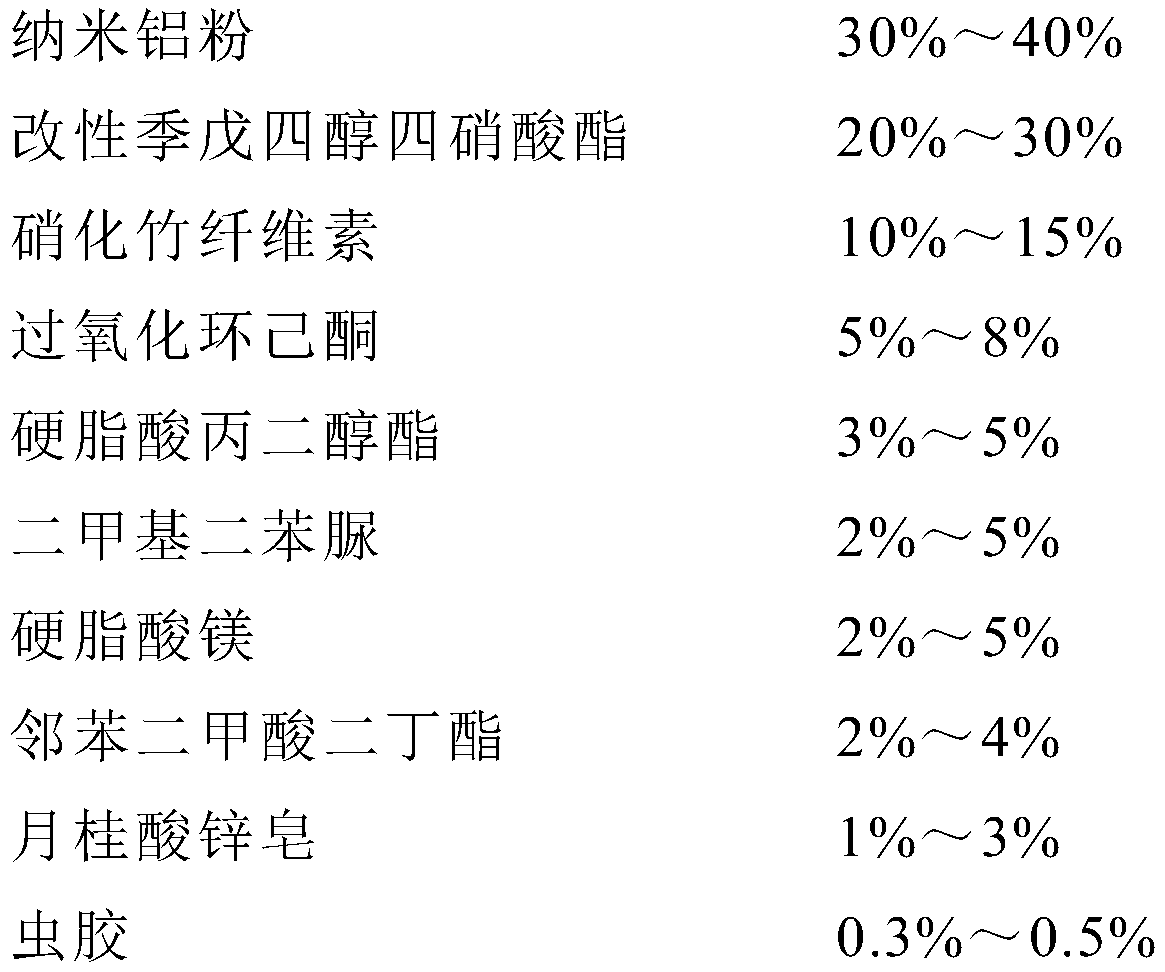

[0038] An eco-friendly antistatic smokeless and sulfur-free cold smoke flower agent, the mass percentage of each component is as follows:

[0039]

[0040] Take 5.32kg of nitrobamboo cellulose powder and divide it into two groups of A and B, wherein 1.32kg of group A and 4kg of group B, and dissolve the nitrobamboo cellulose powder of group A in 13.2kg of ethyl acetate, and stir under the condition of ultrasonic dispersion 2 hours, then continue under stirring state, add 1.01kg zinc laurate soap powder and 1.66kg magnesium stearate powder, stir, make nitrocellulose mixed sol;

[0041] Add 10kg of pentaerythritol tetranitrate powder and 0.7kg of titanate coupling agent to 100kg of acetone, and disperse it ultrasonically for 45 minutes to obtain a mixed solution C; transfer the mixed solution C to an ice-water bath for stirring; then add 0.22kg of polyethylene Add the alcohol butyral adhesive to the mixed solution C and stir for 4 hours; transfer the reaction device to an oil...

Embodiment 3

[0049] An eco-friendly antistatic smokeless and sulfur-free cold smoke flower agent, the mass percentage of each component is as follows:

[0050]

[0051] Take 19.53kg of nitrobamboo cellulose powder and divide it into two groups, A and B, wherein group A is 4.53kg and group B is 14kg. Dissolve the nitrobamboo cellulose powder in group A in 45.3kg of ethyl acetate and stir under ultrasonic dispersion conditions 2.5 hours, then continue under stirring state, add 2.38kg zinc laurate soap powder and 5.18kg magnesium stearate powder, stir, make nitrocellulose mixed sol;

[0052] Add 36kg of pentaerythritol tetranitrate powder and 1.92kg of titanate coupling agent to 360kg of acetone and disperse ultrasonically for 50 minutes to obtain mixed solution C; transfer mixed solution C to an ice-water bath for stirring; then add 0.75kg of polyethylene Add the alcohol butyral adhesive to the mixed solution C and stir for 4 hours; transfer the reaction device to an oil bath at 75°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

| Surface resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com